Expansion process for cut tobacco

A processing technology and shredded tobacco technology, which is applied in the field of shredded tobacco expansion processing technology, can solve the problems of insufficient reduction of cigarette tar and insufficient expansion rate of shredded tobacco, etc., and achieve good expansion effect, reduce the amount of shredded tobacco, and reduce the amount of tar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

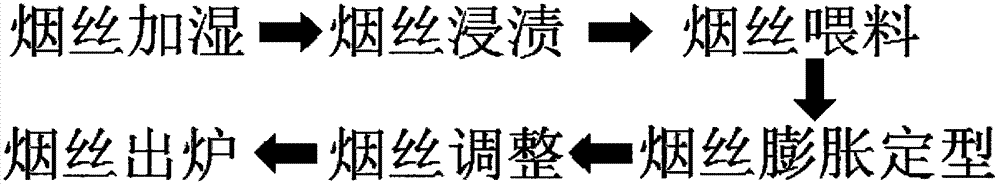

[0017] Such as figure 1 Shown, this shredded tobacco expansion processing technology comprises the steps:

[0018] (1) Humidification of shredded tobacco: use a humidifier to humidify the shredded tobacco, and use a humidity sensor to monitor the humidity of the shredded tobacco, and humidify the shredded tobacco until its moisture content is 5% to 25%;

[0019] (2) Shredded tobacco impregnation: Put moist shredded tobacco into a sealed heating container, decompress the shredded tobacco in the container so that the pressure is not higher than 6kPa, pass 30-70°C dimethyl ether vapor into the container to make The pressure is raised to 500-1100kPa, and the pressure is maintained for 20-40 minutes to fully impregnate the shredded tobacco with dimethyl ether vapor;

[0020] (3) Shredded tobacco feeding: send the shredded tobacco after impregnation to a screening feeder to apply feed liquid in proportion to improve and enhance the sensory quality of shredded tobacco;

[0021] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com