Steam control method of a garment steamer and the garment steamer

A control method and technology for a garment ironing machine, applied in the field of fabric ironing, can solve the problems of water spraying of the ironing head, discontinuous steam, etc., and achieve the effects of improving reliability and stability, and avoiding the discontinuous steam and water spraying of the ironing head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

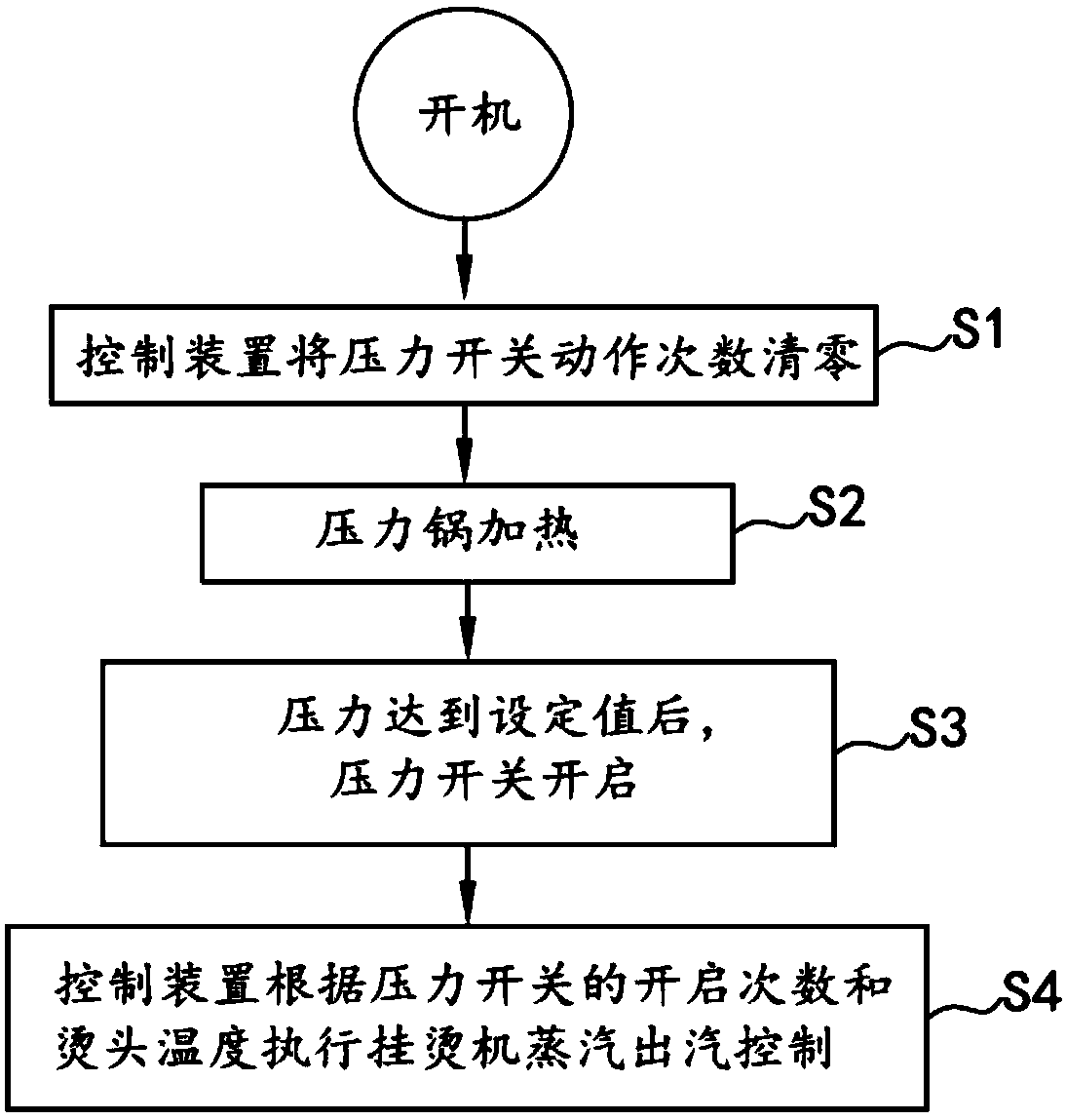

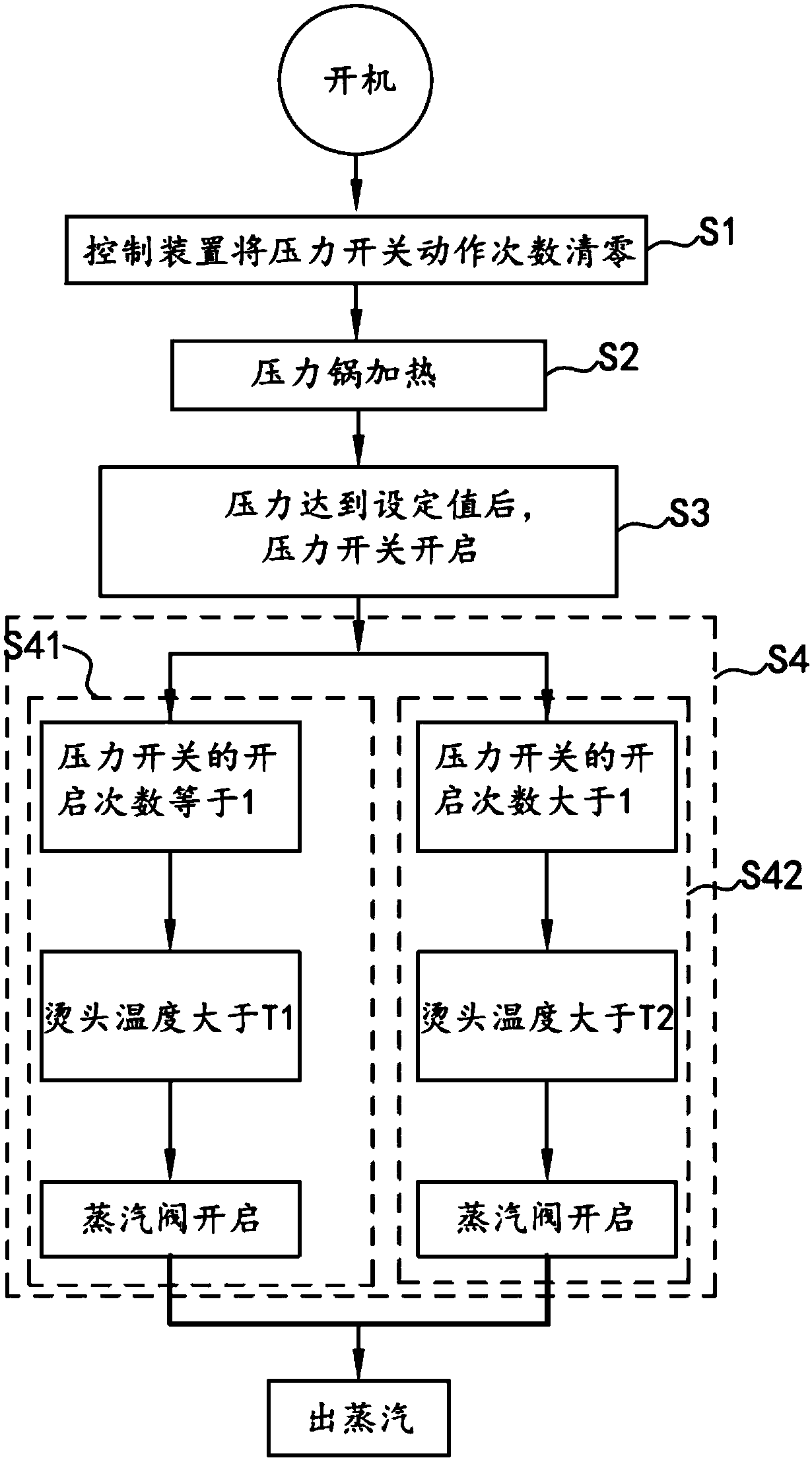

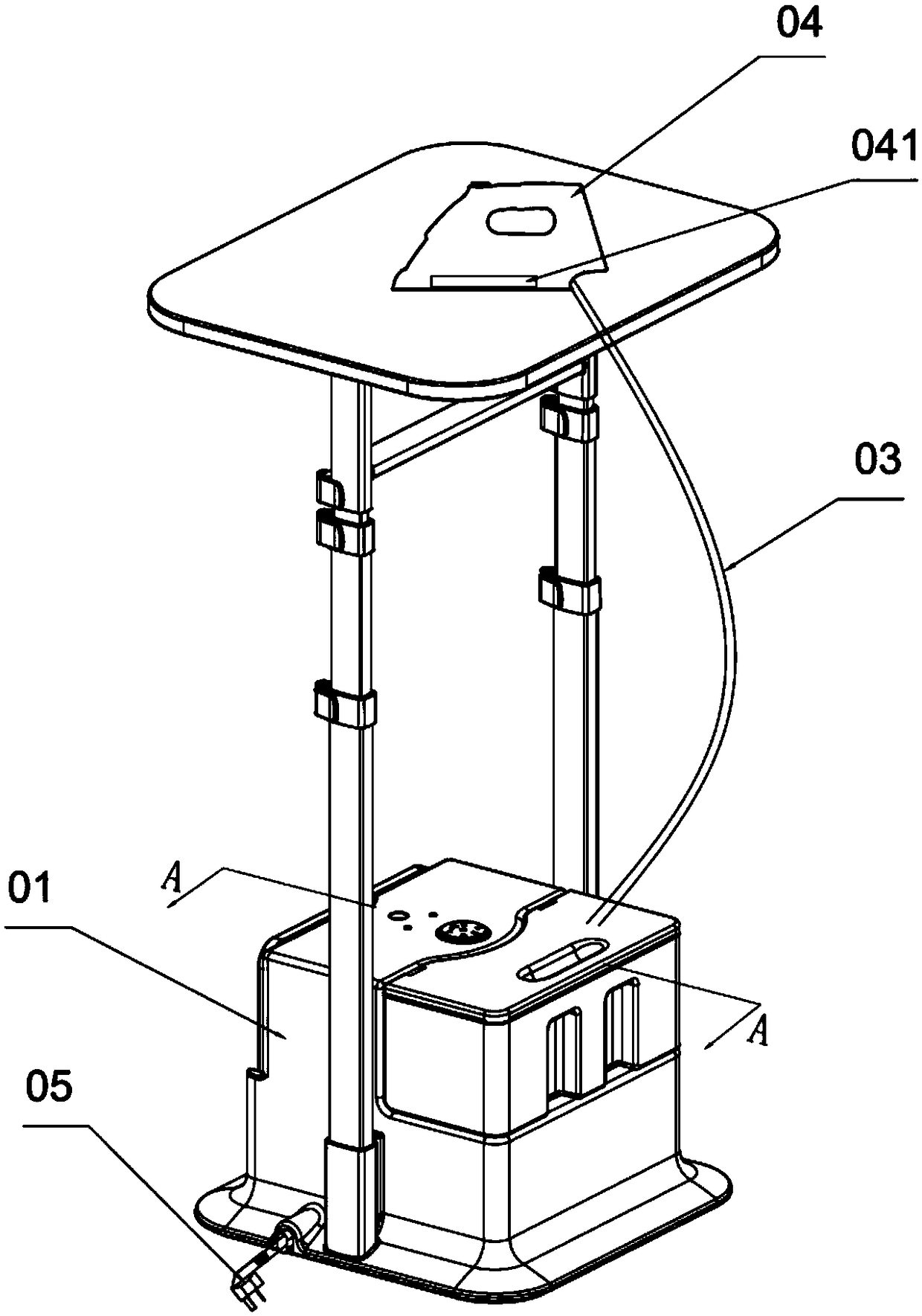

[0041] The steam control method of the garment ironing machine of the present invention, wherein the garment ironing machine refers to image 3 , including a pressure hot pot 02 for heating water into steam, a pressure switch 023 for controlling the steam outlet pressure of the pressure hot pot 02, a steam switch for controlling the steam outlet, an ironing head 04 and a reheating device for reheating the steam in the ironing head 04 For the iron heating body 041, and the control device 06 for controlling the iron heating body, the steam switch, the pressure switch 023 and the pressure hot pot 02, the control flow chart of Embodiment 1 can be found in figure 1 , the steam control method comprises the following steps:

[0042] Step S1, the control device 06 clears the number of times the pressure switch 023 operates;

[0043] Step S2, the control devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com