Ultra-narrow gap TIG (tungsten inert gas) hot wire welding method

A welding method and narrow gap technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of high operation difficulty and poor processing accuracy, reduce the number of preheating times, reduce production costs, and prevent side wall fusion bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0046] In the following description, many specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways than those described here, so the present invention is not limited by the specific embodiments disclosed below.

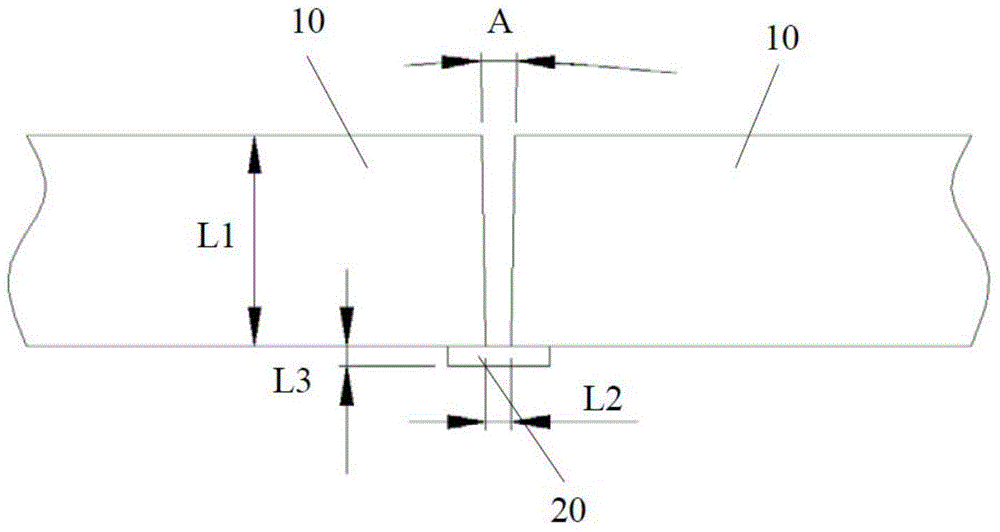

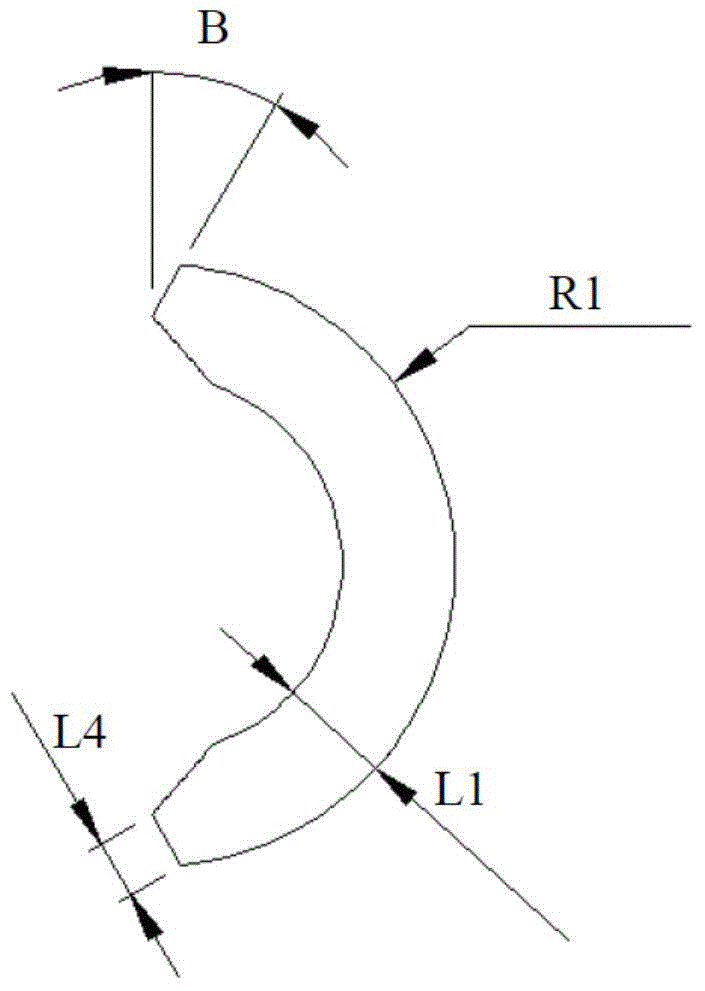

[0047] The invention proposes an ultra-narrow-gap hot wire TIG welding method, which can realize all-position high-efficiency bottoming welding of ultra-narrow-gap thick plates of high-strength steel, and is suitable for piles of large-scale marine steel structures (such as jack-up offshore oil drilling platforms) Welding manufacturing field of legs. On the basis of a large number of actual welding experiments and researches, the causes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com