Semi-hard type cable steel and production method thereof

A production method and cable steel technology, applied in the field of steel for cables, can solve problems such as ineffective decarburization, and achieve the effects of meeting production requirements, solving easy hardening, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

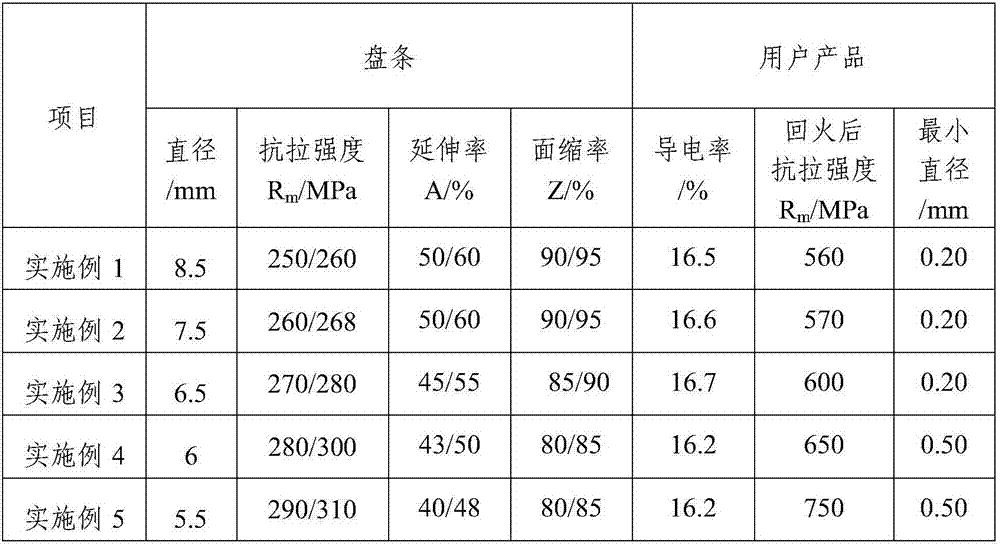

Examples

Embodiment 1

[0029] The mass percentage of the chemical composition of a semi-rigid cable steel is: C: 0.001%, Si: 0.02%, Mn: 0.10%, P: 0.020%, S: 0.010%, Als: 0.01%, the rest is Fe and not Avoid impurities, and the above elements satisfy Cu+Ni+Cr+Mo≤0.030%. Its production method comprises the following steps:

[0030] 1) Hot metal desulfurization: the mass percentage of each element in the incoming hot metal is: S ≤ 0.025%, Mn ≤ 0.30%, Cu ≤ 0.060%, Si ≤ 0.80%, and the mass percentage of sulfur in the molten iron is controlled to be S ≤ 0.001%;

[0031] 2) Converter smelting: the end-point carbon control target is 0.06%, the mass percentage of oxygen is controlled at 0.040-0.070%, the slag is blocked and the steel is tapped, the thickness of the slag layer is ≤50mm, the final slag basicity is 3.0-4.0, and the tapping temperature is controlled at 1680- 1700°C;

[0032] 3) Argon blowing: Sprinkle 0.1-0.5kg / ton of Al pellets on the slag surface, 0.1-0.3kg / ton of calcium carbide / steel, reduc...

Embodiment 2

[0041]The mass percentage of the chemical composition of a semi-rigid cable steel is: C: 0.003%, Si: 0.015%, Mn: 0.08%, P: 0.015%, S: 0.007%, Als: 0.009%, the rest is Fe and not Avoid impurities, and the above elements satisfy Cu+Ni+Cr+Mo≤0.030%. Its production method comprises the following steps:

[0042] 1) Hot metal desulfurization: the mass percentage of each element in the incoming hot metal is: S ≤ 0.025%, Mn ≤ 0.30%, Cu ≤ 0.060%, Si ≤ 0.80%, and the mass percentage of sulfur in the molten iron is controlled to be S ≤ 0.001%;

[0043] 2) Converter smelting: the end-point carbon control target is 0.06%, the mass percentage of oxygen is controlled at 0.040-0.070%, the slag is blocked and the steel is tapped, the thickness of the slag layer is ≤50mm, the final slag basicity is 3.0-4.0, and the tapping temperature is controlled at 1680- 1700°C;

[0044] 3) Argon blowing: Sprinkle 0.1-0.5kg / ton of Al pellets on the slag surface, 0.1-0.3kg / ton of calcium carbide / steel, redu...

Embodiment 3

[0053] The mass percentage of the chemical composition of a semi-rigid cable steel is: C: 0.005%, Si: 0.01%, Mn: 0.07%, P: 0.013%, S: 0.006%, Als: 0.008%, the rest is Fe and not Avoid impurities, and the above elements satisfy Cu+Ni+Cr+Mo≤0.030%. Its production method comprises the following steps:

[0054] 1) Hot metal desulfurization: the mass percentage of each element in the incoming hot metal is: S ≤ 0.025%, Mn ≤ 0.30%, Cu ≤ 0.060%, Si ≤ 0.80%, and the mass percentage of sulfur in the molten iron is controlled to be S ≤ 0.001%;

[0055] 2) Converter smelting: the end-point carbon control target is 0.06%, the mass percentage of oxygen is controlled at 0.040-0.070%, the slag is blocked and the steel is tapped, the thickness of the slag layer is ≤50mm, the final slag basicity is 3.0-4.0, and the tapping temperature is controlled at 1680- 1700°C;

[0056] 3) Argon blowing: Sprinkle 0.1-0.5kg / ton of Al pellets on the slag surface, 0.1-0.3kg / ton of calcium carbide / steel, redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com