Graphene enhanced water permeable brick and preparation method thereof

A graphene and permeable brick technology, applied in the field of permeable brick and its preparation, can solve the problems of increased cost, high energy consumption in the sintering process, and high repair rate, and achieve the effects of reducing cracking, excellent air permeability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

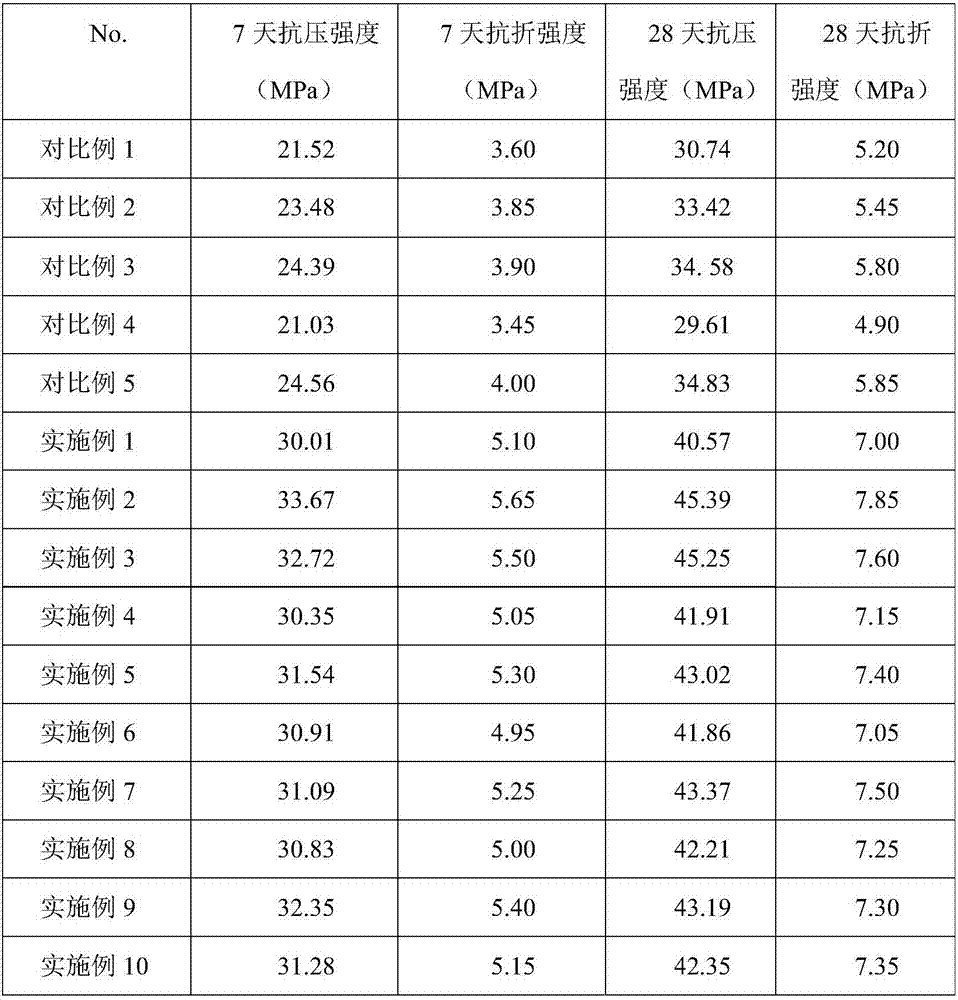

Examples

Embodiment 1

[0042] (1) Add 0.34g of polymer surfactant to 1kg of water, add 34g of graphene and 136g of graphene oxide, stir at 240r / min for 10min, then ultrasonicate at 300W for 5min, add 25.5kg of water under stirring at 240r / min , and continue to stir for 5 minutes to form a graphene carbon material dispersion.

[0043] (2) Add 159.4kg of quartz sand and 30kg of cement into the mixer, pre-mix for 1min at a speed of 120r / min, add 5.3kg of graphene carbon material dispersion and 5.3kg of water under stirring, continue stirring for 3min before using the surface layer for processing Mechanism top layer.

[0044] (3) Add 115.4kg of gravel, 40kg of fine sand and 34kg of cement into the mixer, pre-mix for 1min at a speed of 120r / min, add 2.65kg of graphene carbon material dispersion and 7.95kg of water under stirring, and continue stirring for 3min The bottom layer is made using the bottom layer processor.

[0045] (4) Put the prepared bottom layer into the mold cavity, put the surface laye...

Embodiment 2

[0047] Embodiment 2: the best embodiment

[0048] (1) Add 0.34g of polymer surfactant to 1kg of water, add 34g of graphene and 136g of graphene oxide, stir at 240r / min for 10min, then ultrasonicate at 300W for 5min, add 25.5kg of water under stirring at 240r / min , and continue to stir for 5 minutes to form a graphene carbon material dispersion.

[0049] (2) Add 155.4kg of quartz sand and 34kg of cement into the mixer, pre-mix for 1min at a speed of 120r / min, add 5.3kg of graphene carbon material dispersion and 5.3kg of water under stirring, continue stirring for 3min and use the surface layer for processing Mechanism top layer.

[0050](3) Add 115.4kg of gravel, 40kg of fine sand and 34kg of cement into the mixer, pre-mix for 1min at a speed of 120r / min, add 2.65kg of graphene carbon material dispersion and 7.95kg of water under stirring, and continue stirring for 3min The bottom layer is made using the bottom layer processor.

[0051] (4) Put the prepared bottom layer into...

Embodiment 3

[0054] (1) Add 0.34g of polymer surfactant to 1kg of water, add 34g of graphene and 136g of graphene oxide, stir at 240r / min for 10min, then ultrasonicate at 300W for 5min, add 25.5kg of water under stirring at 240r / min , and continue to stir for 5 minutes to form a graphene carbon material dispersion.

[0055] (2) Add 149.4kg of quartz sand and 40kg of cement into the mixer, pre-mix for 1min at a speed of 120r / min, add 5.3kg of graphene carbon material dispersion and 5.3kg of water under stirring, continue stirring for 3min and then use the surface layer for processing Mechanism top layer.

[0056] (3) Add 115.4kg of gravel, 40kg of fine sand and 34kg of cement into the mixer, pre-mix for 1min at a speed of 120r / min, add 2.65kg of graphene carbon material dispersion and 7.95kg of water under stirring, and continue stirring for 3min The bottom layer is made using the bottom layer processor.

[0057] (4) Put the prepared bottom layer into the mold cavity, put the surface laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com