Preparation method for cottonseed meal protein fodder

A technology of protein feed and cotton meal, which is applied in the field of preparation of cotton meal protein feed, can solve the problems of low content of essential amino acids such as methionine, little consideration, and poor protein quality, so as to reduce the content of free gossypol and improve the ratio of amino acids , the effect of increasing protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

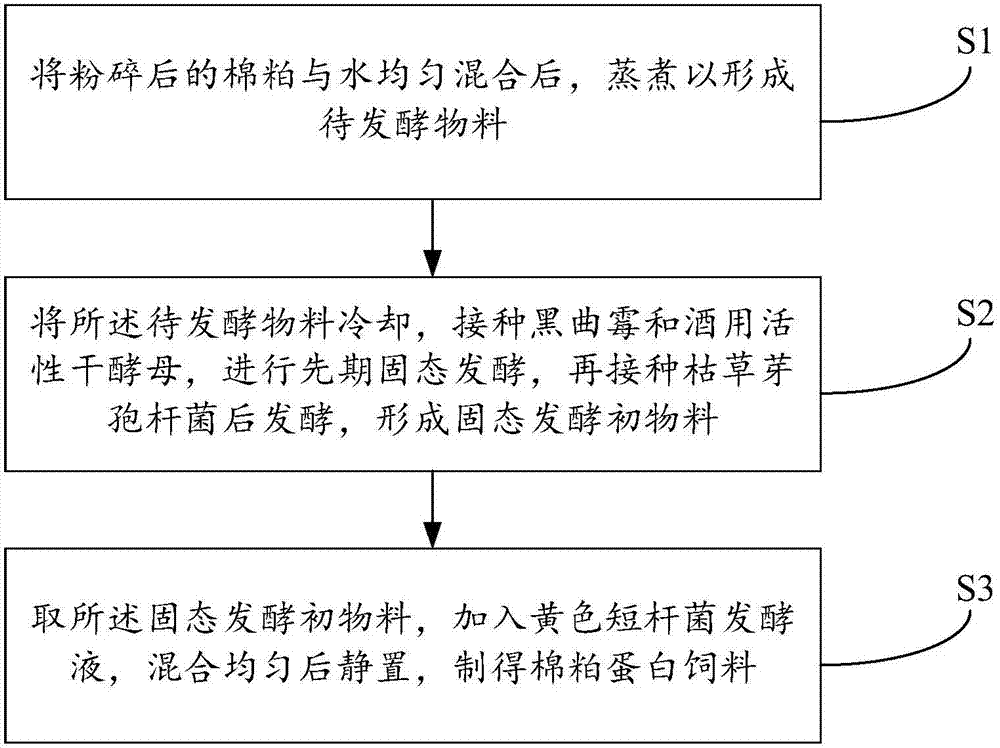

[0031] Aiming at the defects of low cottonseed meal protein content in the prior art, low removal rate of other anti-nutritional factors except free gossypol, and high production cost, the present invention proposes a preparation method of cottonseed meal protein feed, such as figure 1 shown, including the following steps:

[0032] Step S1, after uniformly mixing the pulverized cottonseed meal with water, steaming to form the material to be fermented;

[0033] Optionally, step S1 includes: mixing 100 parts (parts by mass) of pulverized cottonseed meal with water and then cooking, wherein the weight-to-volume ratio of the cottonseed meal to water is 5:4 to 1:1, and the cooking temperature is The temperature is 120~122℃, and the cooking time is 15~20min.

[0034] Step S2, cooling the material to be fermented, inoculating Aspergillus niger and active dry yeast for wine, performing solid-state fermentation in advance, and then inoculating Bacillus subtilis for fermentation to for...

Embodiment 1

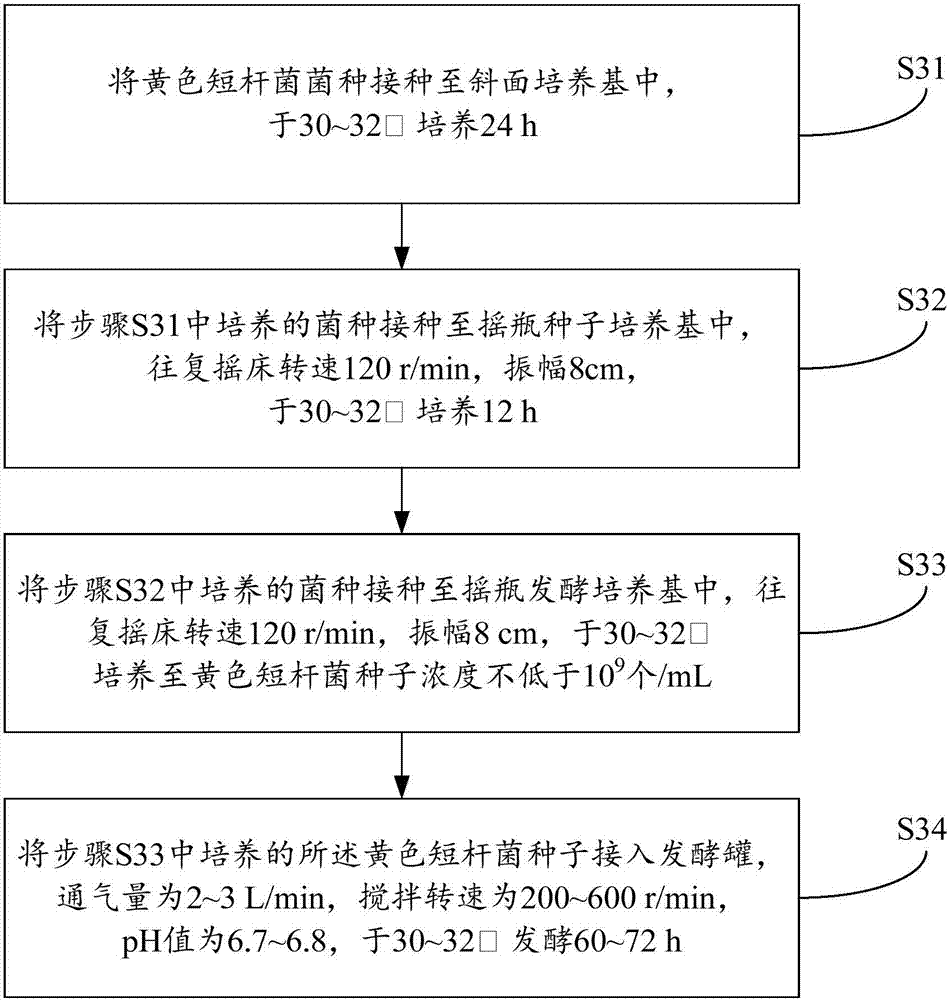

[0051] The preparation materials are as follows: Brevibacterium flavum strains are cultured on the above slope, shake flask culture, shake flask fermentation culture and fermenter fermentation to prepare the Brevibacterium flavum fermentation liquid, and the dry cottonseed meal is crushed, and set aside.

[0052] Preparation of materials to be fermented: Take 10kg of dry cottonseed meal, add water at a weight-to-volume ratio of 100:100, mix well, and steam at 121°C for 15 minutes to form materials to be fermented;

[0053] Preparation of raw materials for solid-state fermentation: Inoculate the material to be fermented (according to the weight of cottonseed dry material) with 0.4% Aspergillus niger and 0.05% active dry yeast for wine, solid-state fermentation for 27 hours in advance, and then inoculated with 1% Bacillus subtilis and then fermented for 30 hours to form a solid state The initial material for fermentation, wherein the fermentation temperature is 30°C;

[0054] Co...

Embodiment 2

[0056] The material preparation of embodiment 2 is the same as embodiment 1.

[0057] Preparation of materials to be fermented: Take 10kg of dry cottonseed meal, add water at a weight-to-volume ratio of 100:80, mix well, and cook at 121°C for 15 minutes to form materials to be fermented;

[0058] Preparation of raw material for solid-state fermentation: inoculate the material to be fermented (according to the weight of dry material of cottonseed meal) with 0.2% Aspergillus niger and 0.2% active dry yeast for wine, solid-state fermentation for 36 hours in advance, and then inoculate with 0.5% Bacillus subtilis and then ferment for 60 hours to form a solid state The initial material for fermentation, wherein the fermentation temperature is 30°C;

[0059] Cotton meal protein feed preparation: take the initial material of solid-state fermentation (sampled according to the initial material formed after solid-state fermentation of 100 parts of dry cotton meal), add 0.5 kg of Breviba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com