Magnetorheological shock absorber with external coil

A magneto-rheological shock absorber and coil technology, applied in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as difficult processing, high cost of long hole processing, structural optimization, and complex piston structure , to achieve the effect of reducing the difficulty of processing and assembly, which is conducive to long-term stability and heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the drawings and specific embodiments. It should be understood that the following specific embodiments are only used for the present invention but not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions indicated in the drawings.

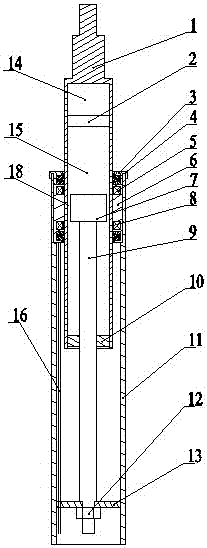

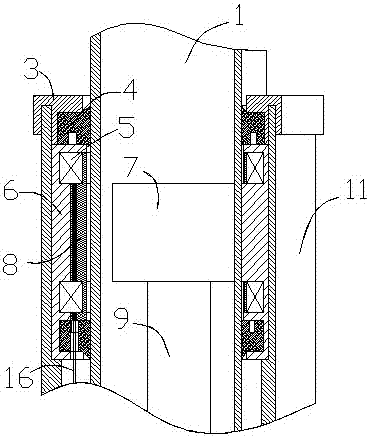

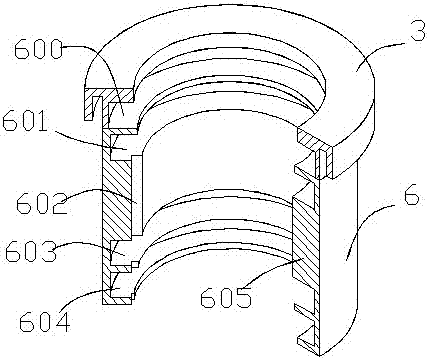

[0019] Such as figure 1 The magnetorheological shock absorber with external coil shown includes: hydraulic cylinder 1, floating piston 2, piston 7, piston rod 9, sealing cover 10, coil 5, outer cylinder 11, dust ring 4 , Outer end cover 3, bottom stopper 13, nut 12 and sleeve 6. The floating piston 2 functions to separate the compensation air chamber 14 from the hydraulic chamber 15. The piston 7 is connected to the piston rod 9 and is located inside the hydraulic cylinder block 1. The piston rod 9 passes through the sealing cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com