Metal printing UV varnish and coating method thereof

A metal and varnish technology, applied in the direction of epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high cost of VOC pollution discharge fees, VOC treatment costs, bubbles, shrinkage cavities, etc., to meet most of the curing requirements Necessary, high photocuring efficiency, effect of increasing gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

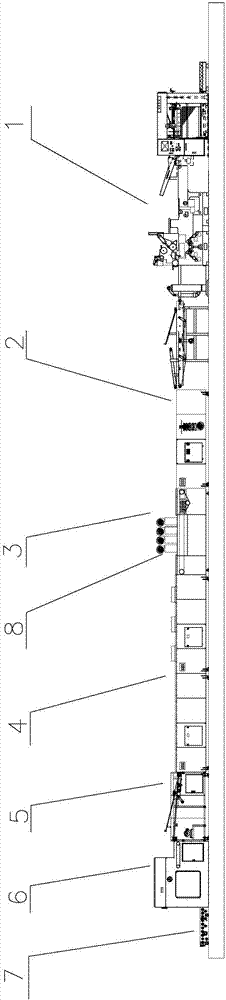

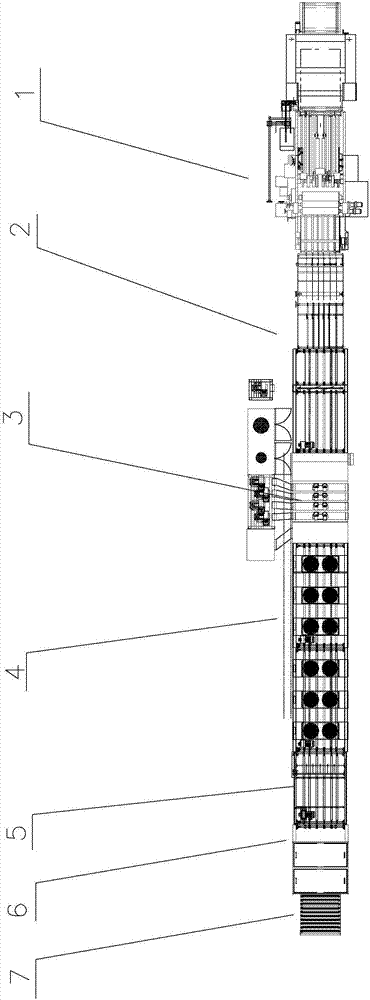

Image

Examples

Embodiment 1

[0041] A metal printing UV varnish, including the following components by mass percentage:

[0042] Light curing resin prepolymer (modified epoxy acrylic resin) 45%,

[0043] Active monomer (20% ethoxy acrylate, 10% hexanediol diacrylate, 10% acryloyl morpholine) 40%,

[0044] Photoinitiator (TPO(75980-60-8) 8%, active amine 2%) 10%,

[0045] Acrylic leveling agent 2%,

[0047] Modified PTFE wax 1%.

Embodiment 2

[0049] A metal printing UV varnish, including the following components by mass percentage:

[0050] Light curing resin prepolymer (modified polyurethane acrylic resin) 30%,

[0051] Active monomer (15% trihydroxy acrylate, 20% hydroxyethyl methacrylate, 10% tripropylene glycol diacrylate) 45%,

[0052] Photoinitiator (TPO-L(84434-11-7) 5%, active amine 5%) 10%,

[0053] Silicon leveling agent 5%,

[0055] Modified PTFE wax 5%.

Embodiment 3

[0057] A metal printing UV varnish, including the following components by mass percentage:

[0058] Light curing resin prepolymer (diallyl phthalate) 60%,

[0059] Active monomer (15% ethoxy acrylate, 15% tripropylene glycol diacrylate) 30%,

[0060] Photoinitiator (Irgacure 184(947-19-3) 5%),

[0061] Acrylic leveling agent 2%,

[0063] Modified PTFE wax 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com