Wood sawing device for bridge construction

A construction and sawing technology, which is applied in the field of sawing devices for bridge construction, can solve the problems of slow cutting speed, time-consuming and labor-intensive work, and eye injuries of cutting personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

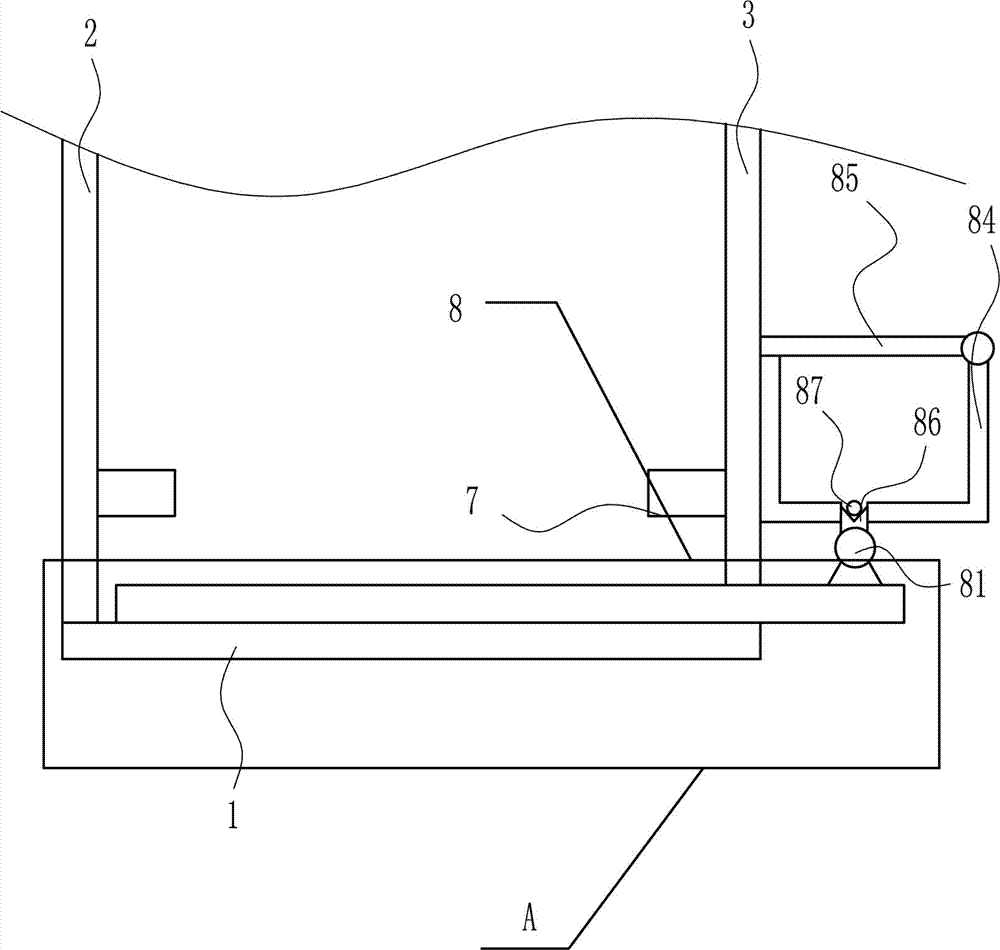

[0039] A sawmill for bridge construction, such as Figure 1-8 As shown, it includes a bottom plate 1, a left support plate 2, a right support plate 3, a top plate 4, a lifting device 5, a cutting device 6, and a placement plate 7. The left support plate 2 is installed on the left side of the top of the bottom plate 1, and the right side of the top of the bottom plate 1 A right support plate 3 is installed, a top plate 4 is installed between the top of the left support plate 2 and the top of the right support plate 3, and a lifting device 5 is arranged between the top of the right side of the left support plate 2 and the top of the left side of the right support plate 3, The lifting part of lifting device 5 is provided with cutting device 6, and left support plate 2 right side bottoms and right support plate 3 left side bottoms are all equipped with placing plate 7, and placing plate 7 is symmetrically arranged.

Embodiment 2

[0041] A sawmill for bridge construction, such as Figure 1-8 As shown, it includes a bottom plate 1, a left support plate 2, a right support plate 3, a top plate 4, a lifting device 5, a cutting device 6, and a placement plate 7. The left support plate 2 is installed on the left side of the top of the bottom plate 1, and the right side of the top of the bottom plate 1 A right support plate 3 is installed, a top plate 4 is installed between the top of the left support plate 2 and the top of the right support plate 3, and a lifting device 5 is arranged between the top of the right side of the left support plate 2 and the top of the left side of the right support plate 3, The lifting part of lifting device 5 is provided with cutting device 6, and left support plate 2 right side bottoms and right support plate 3 left side bottoms are all equipped with placing plate 7, and placing plate 7 is symmetrically arranged.

[0042] Lifting device 5 comprises first motor 51, bearing block ...

Embodiment 3

[0044] A sawmill for bridge construction, such as Figure 1-8 As shown, it includes a bottom plate 1, a left support plate 2, a right support plate 3, a top plate 4, a lifting device 5, a cutting device 6, and a placement plate 7. The left support plate 2 is installed on the left side of the top of the bottom plate 1, and the right side of the top of the bottom plate 1 A right support plate 3 is installed, a top plate 4 is installed between the top of the left support plate 2 and the top of the right support plate 3, and a lifting device 5 is arranged between the top of the right side of the left support plate 2 and the top of the left side of the right support plate 3, The lifting part of lifting device 5 is provided with cutting device 6, and left support plate 2 right side bottoms and right support plate 3 left side bottoms are all equipped with placing plate 7, and placing plate 7 is symmetrically arranged.

[0045] Lifting device 5 comprises first motor 51, bearing block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com