Welding method for jack cylinder-barrel accessory

The technology of a jack cylinder and a welding method is applied in the field of jack manufacturing, which can solve the problems affecting the service life of the product and the deformation of the cylinder barrel, and achieve the effects of reducing heat input, reducing product failure rate and improving overall quality level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The welding method of the present invention will be described in more detail below by welding the liquid-through seat on the surface of the cylinder (it can also be a joint seat, etc., the method is the same).

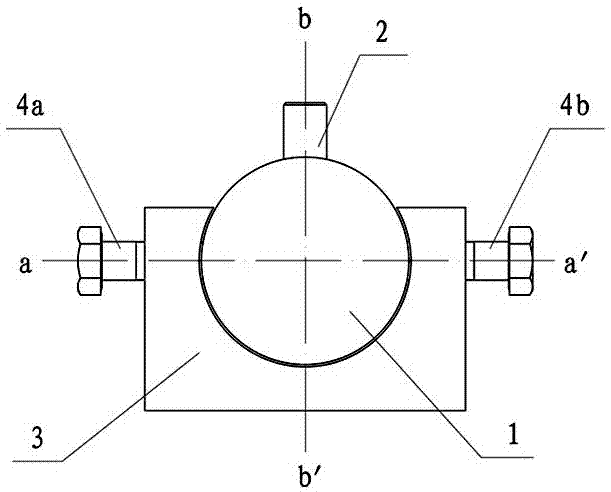

[0021] Such as Figure 1-3 As shown, the present invention welds the liquid-through seat on the cylinder barrel of the jack, and the steps are:

[0022] The first step is to draw the assembly boundary line and the vertical and horizontal centerline of the liquid seat 2 on the cylinder 1 made of 27SiMn or 30CrMo, and determine the tailor welding position of the liquid seat 2;

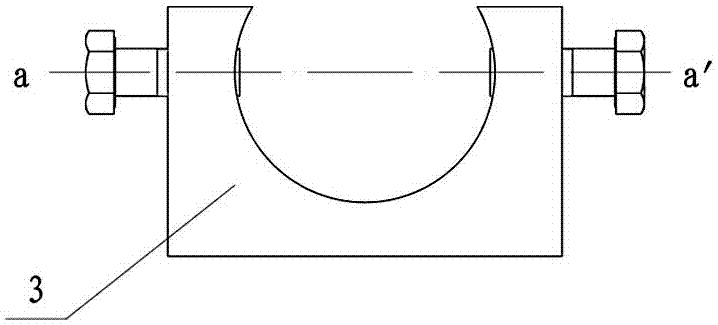

[0023] In the second step, set the cylinder on cylinder 1 as figure 1 The shown profiling ferrule 3 with threaded holes on both sides, when the bore diameter of the cylinder is 140-250mm, the profiling ferrule 3 can be made of Q690 high-strength steel, its thickness δ is 40mm, and it is made by quenching and tempering. It can play a good role in clamping the cylinder; if figure 2 , 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com