Heat dissipation structure for electric welding machine

A technology of heat dissipation structure and electric welding machine, which is applied in the direction of welding accessories, etc., can solve the problems of poor heat dissipation effect and complex structure, and achieve the effect of improving heat dissipation effect and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

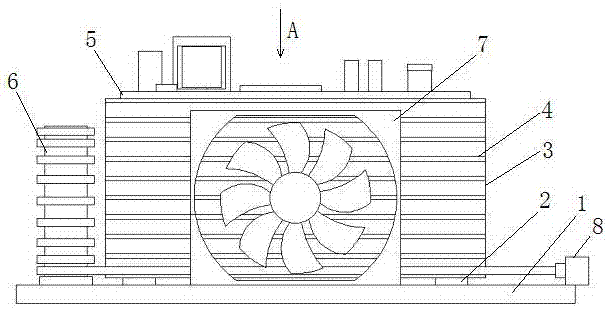

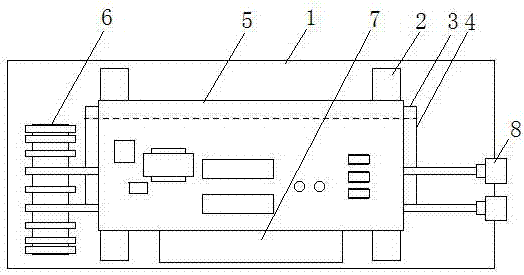

[0014] Such as figure 1 and figure 2 The shown heat dissipation structure of an electric welding machine includes a bottom plate 1 of the electric welding machine, a control circuit board 5, a transformer 6 and a fan 7, and also includes an aluminum substrate 3 whose bottom end is vertically installed on the bottom plate 1 through a ceramic or silica gel isolation pad 2 , the front of the aluminum substrate 3 is provided with multi-layer horizontal aluminum heat sinks 4, the aluminum substrate 3 and the aluminum heat sink 4 are integrally formed, the control circuit board 5 is connected to the upper surface of the top aluminum heat sink 4, The transformer 6 is arranged on one side of the aluminum heat sink 4 , the terminal 8 of the transformer 6 extends to the other side of the aluminum heat sink, the fan 7 is arranged in the front middle of the aluminum substrate 3 , and the air outlet faces the aluminum substrate 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com