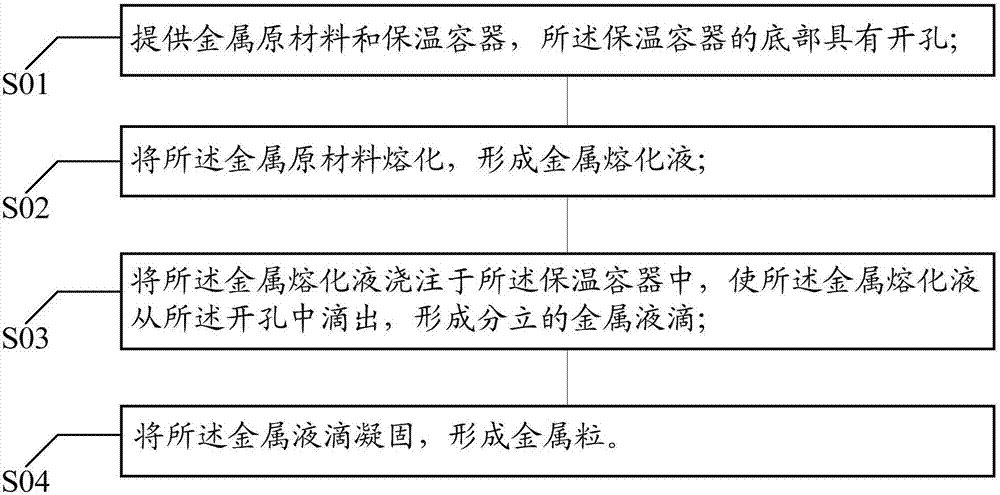

Metal particle forming method and metal particle preparing device

A technology of metal grains and metals, applied in the field of forming methods and devices for preparing metal grains, can solve the problems that the purity of metal grains and the production efficiency of metal grains are difficult to be guaranteed at the same time, and achieve the effects of facilitating subsequent cleaning, improving process efficiency, and ensuring purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

[0086] The difference between the second embodiment and the first embodiment is that: after the metal particles are formed, the metal particles are cleaned to further improve the purity of the metal particles.

[0087] In this embodiment, the metal particles are cleaned to remove impurities on the surface of the metal particles to further improve the purity of the metal particles; at the same time, since there are fewer impurities on the surface of the metal particles, it is not necessary to use more cycles of repeated cleaning, and the efficiency Higher; and because the formation of metal particles by mechanical processing is avoided, a small amount of impurities will not be embedded in metal particles, thus reducing the difficulty of cleaning.

[0088] Specifically, a cleaning solution is used to clean the metal particles.

[0089] If the metal particles are exposed to oil pollutants, such as oil film materials, it is necessary to remove the oil pollutants on the surface of ...

no. 3 example

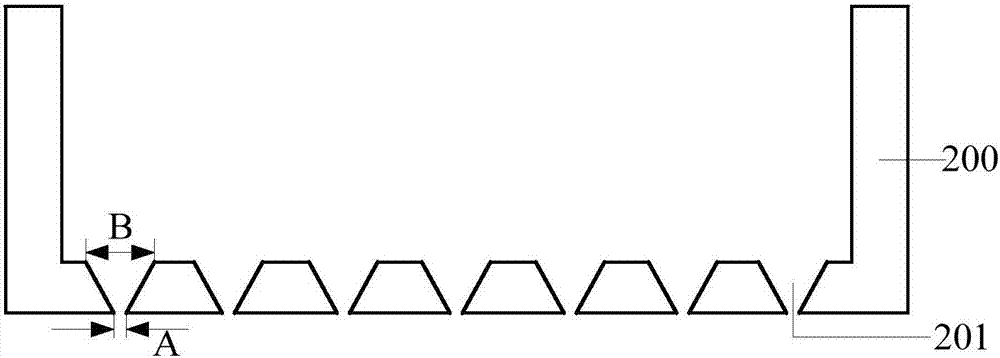

[0097] This embodiment provides a device for preparing metal particles, including: a melting furnace 300 (refer to Figure 4 ), the melting furnace 300 is suitable for melting metal raw materials into molten metal; image 3 ), the bottom of the insulated container 200 has an opening 201 (refer to image 3 ), the insulated container 200 is suitable for accommodating the molten metal, and the opening 201 is used as a channel for the molten metal to drip from the insulated container 200 to form metal droplets; the collector 400 (refer to Image 6 ), the collector 400 is suitable for solidifying the metal droplets into metal particles and collecting the metal particles.

[0098] For the description of the melting furnace 300 , the heat preservation container 200 and the collector 400 refer to the first embodiment, and will not be described in detail again.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com