Novel atomization device and use method thereof

A spray device, a new type of technology, applied in the direction of spray device, liquid spray device, application, etc., can solve problems such as discomfort, trouble to use, operation into the ear or bronchus, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

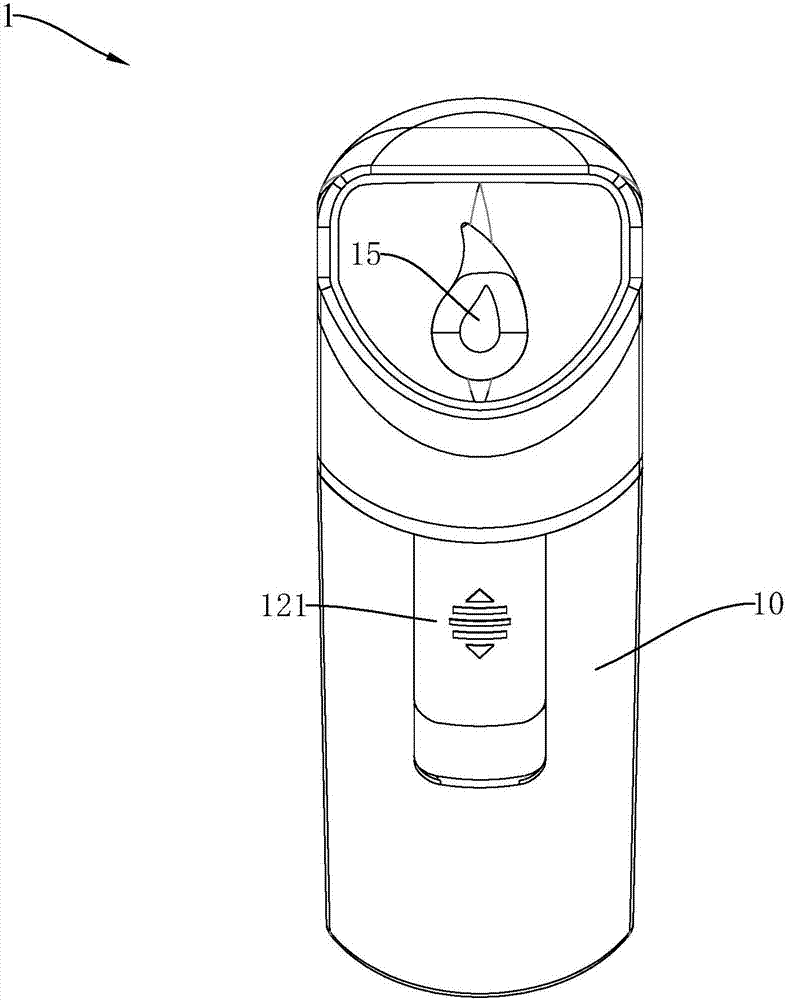

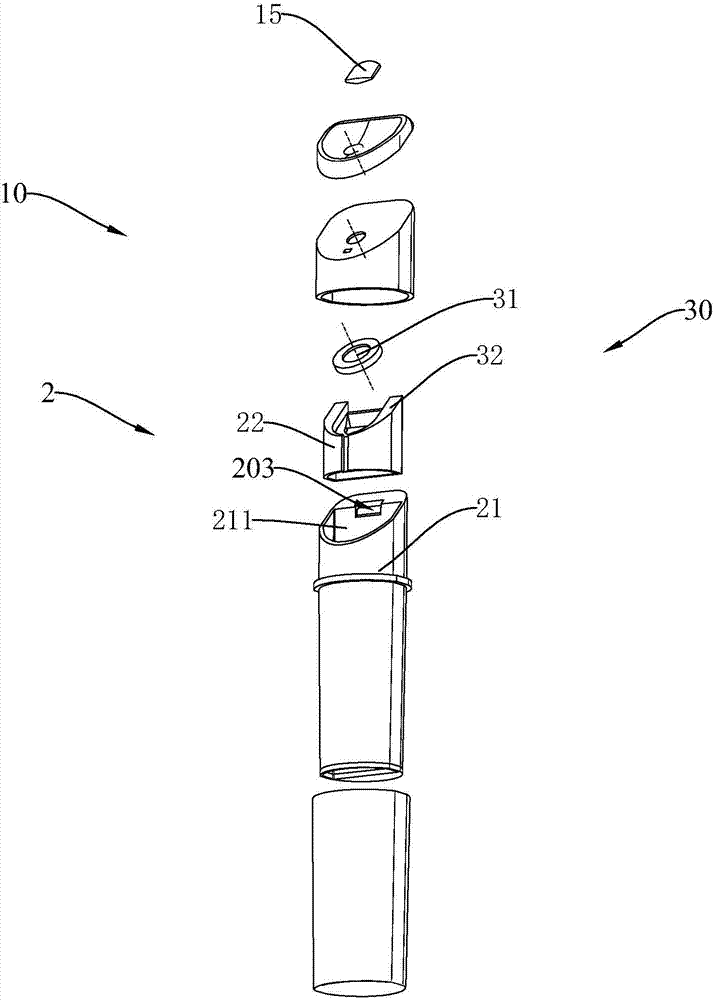

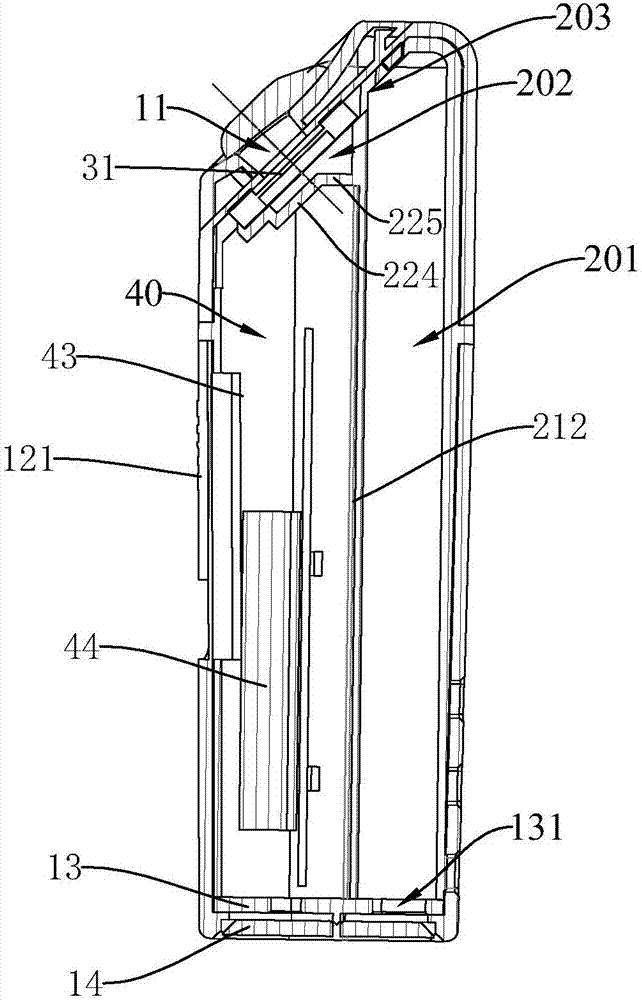

[0042] Such as Figure 1 to Figure 7B Shown is a novel spray device 1, the novel spray device 1 comprises an outer casing 10 and a fluid distribution system 2 installed in the outer casing 10, the outer casing 10 is provided with a spray port 11, and the spray port 11 Opened on the top of the outer shell 10, the fluid distribution system 2 includes a liquid distribution module 20, an atomization assembly 30 and a control module 40, and the liquid distribution module 20 is provided with a main water chamber 201, an auxiliary water chamber 202 and an inlet A water port 203, the water inlet 203 communicates with the main water chamber 201 and the auxiliary water chamber 202, the liquid in the main water chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com