A kind of high-performance supercapacitor electrode material pani/ceo2/ni(oh)2 multilevel microspheres and preparation method thereof

A technology of supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problem that the interface between polyaniline and metal oxides and hydroxides is not tightly combined, and the composite electrode materials of supercapacitors are difficult to be uniform. Dispersion, affecting electrochemical performance and other problems, to achieve the effects of easy control of dispersibility, mild reaction conditions and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Weigh 0.156g nickel sulfate (NiSO 4 ·6H 2 O), 0.02g cerium ammonium nitrate, 0.03g acrylamide, 0.4g hexamethylenetetramine (C 6 h 12 N 4 ) was dissolved in 20ml deionized water, mixed evenly, and recorded as solution a;

[0022] 2. Then weigh 0.01g CTAB, dissolve 0.015g aniline in 15ml deionized water, add 0.05ml hydrochloric acid dropwise, stir until the mixture is uniform, then slowly add 5ml 0.003g / ml ammonium persulfate solution drop by drop, and let stand for a while Time until the solution is dark green, which is recorded as solution b;

[0023] 3. Mix solution a and dark green solution b, transfer to a reaction kettle lined with polytetrafluoroethylene, and react at 180°C for 6h.

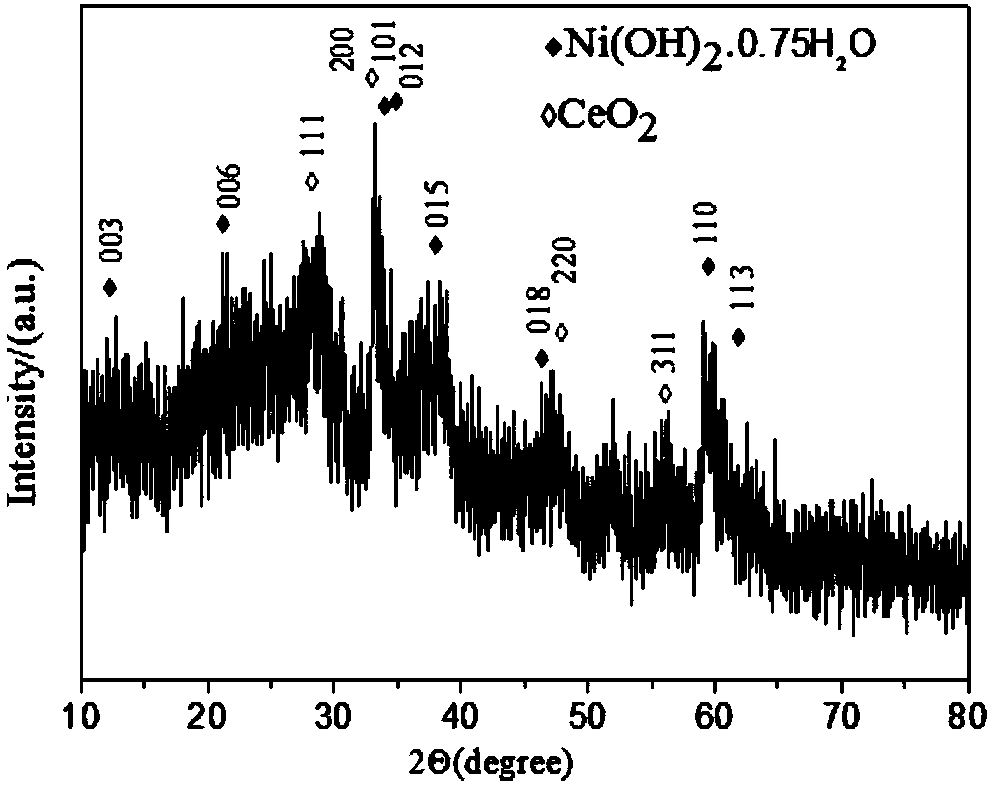

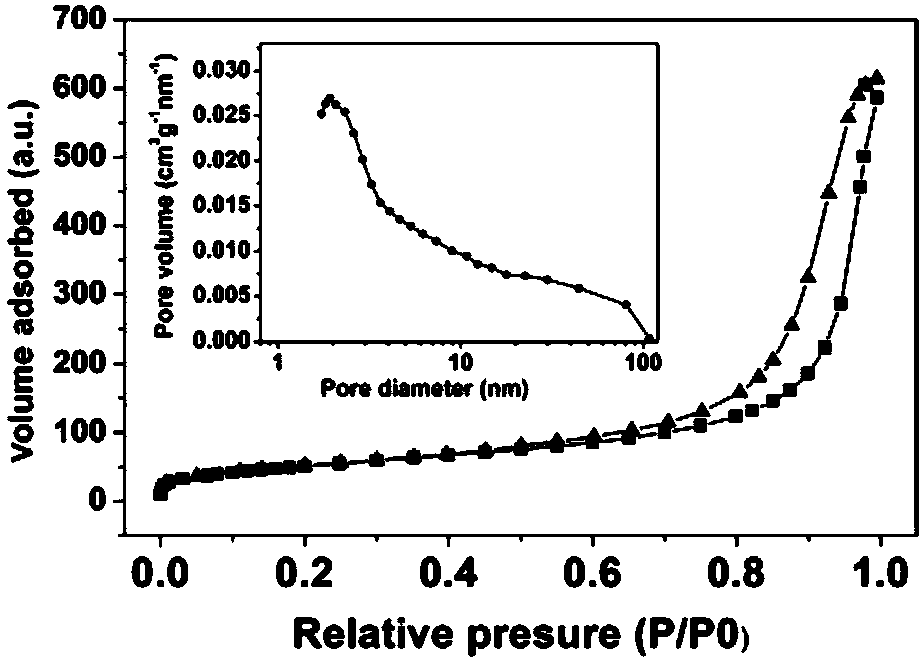

[0024] 4. After the reaction is over, take out the reactor and cool it to room temperature, and centrifuge and wash the precipitate three times with deionized water and absolute ethanol respectively to obtain PANI / CeO 2 / Ni(OH) 2 precipitation.

[0025] 5. Put the precipitat...

Embodiment 2

[0027] 1. Weigh 0.312g nickel sulfate (NiSO 4 ·6H 2 O), 0.04g cerium ammonium nitrate, 0.03g acrylamide, 0.8g hexamethylenetetramine (C 6 h 12 N 4 ) was dissolved in 20ml deionized water, mixed evenly, and recorded as solution a;

[0028] 2. Then weigh 0.01g CTAB, dissolve 0.03g aniline in 15ml deionized water, add dropwise 0.1ml hydrochloric acid, stir until the mixture is uniform, then slowly add 5ml 0.003g / ml ammonium persulfate solution drop by drop, let it stand for a while Time until the solution is dark green, which is recorded as solution b;

[0029] 3. Mix solution a with dark green solution b, transfer to a reaction kettle lined with polytetrafluoroethylene, and react at 180°C for 3 hours.

[0030] 4. After the reaction is over, take out the reactor and cool it to room temperature, and centrifuge and wash the precipitate three times with deionized water and absolute ethanol respectively to obtain PANI / CeO 2 / Ni(OH) 2 precipitation.

[0031] 5. Put the precipi...

Embodiment 3

[0033] 1. Weigh 0.312g nickel sulfate (NiSO 4 ·6H 2 O), 0.04g cerium ammonium nitrate, 0.03g acrylamide, 0.4g hexamethylenetetramine (C 6 h 12 N 4) was dissolved in 20ml deionized water, mixed evenly, and recorded as solution a;

[0034] 2. Then weigh 0.02g CTAB, dissolve 0.015g aniline in 15ml deionized water, add 0.05ml hydrochloric acid dropwise, stir until the mixture is uniform, then slowly add 5ml 0.003g / ml ammonium persulfate solution drop by drop, and let stand for a while Time until the solution is dark green, which is recorded as solution b;

[0035] 3. Mix solution a with dark green solution b, transfer to a reaction kettle lined with polytetrafluoroethylene, and react at 150°C for 9 hours;

[0036] 4. After the reaction is over, take out the reactor and cool it to room temperature, and centrifuge and wash the precipitate three times with deionized water and absolute ethanol respectively to obtain PANI / CeO 2 / Ni(OH) 2 precipitation;

[0037] 5. Put the preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com