On-line detection method for flow characteristic drift amount of fuel gas nozzle

A gas nozzle and flow characteristic technology, which is applied to combustion engines, internal combustion piston engines, engine control, etc., can solve problems such as deviation, difficulty in reflecting the inconsistent air-fuel ratio of a single cylinder, and inability to identify excessive drift of a single gas nozzle flow rate, etc. , to achieve the effect of simple detection method, ensuring safety and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

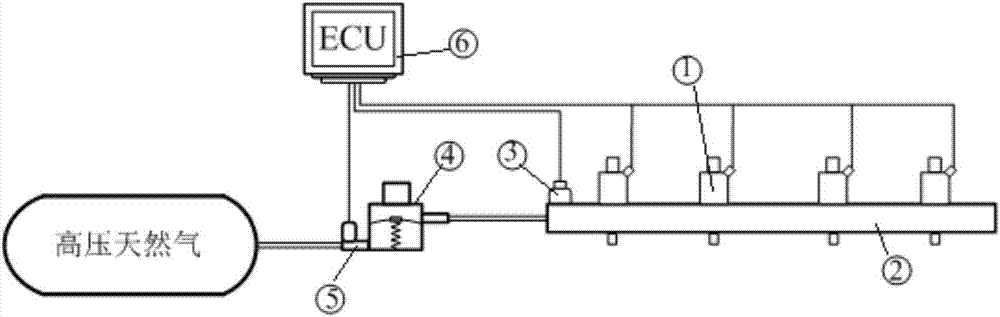

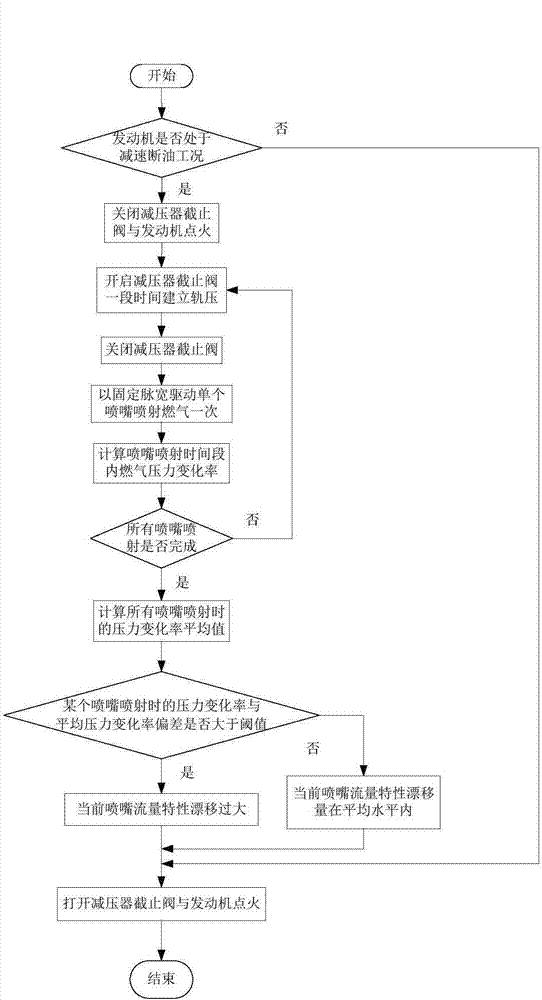

[0027] This embodiment provides an online detection method for the drift of gas nozzle flow characteristics, which is realized by an online detection system. The online detection system includes a gas nozzle 1, a gas rail 2, a gas pressure sensor 3, and a gas pressure reducer 4 , pressure reducer cut-off valve 5, ECU control unit 6 and detection unit;

[0028] High-pressure natural gas passes through the gas shut-off valve 5 and the gas pressure reducer 4, and delivers gas of a given pressure to the gas rail 2;

[0029] The gas pressure sensor 3 is installed on the gas rail 2 for real-time collection of the gas pressure signal in the gas rail (i.e. the gas pressure value in the gas rail);

[0030] The ECU control unit 6 receives the gas pressure signal collected by the gas pressure sensor 3, and the ECU control unit 6 controls a certain gas nozzle to inject gas separately, and records the gas pressure change rate when the gas nozzle is sprayed;

[0031] The detection unit com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com