ATMD vibration damping device for self-powered mass-damped composite structure

A mass damping, composite structure technology, applied in building components, building structures, building types, etc., can solve problems such as large output, energy loss, and ineffective use of electric energy, to optimize the vibration reduction effect and reduce the working space. , the effect of enhancing the power generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below with reference to the accompanying drawings, but the present invention is not limited by specific embodiments.

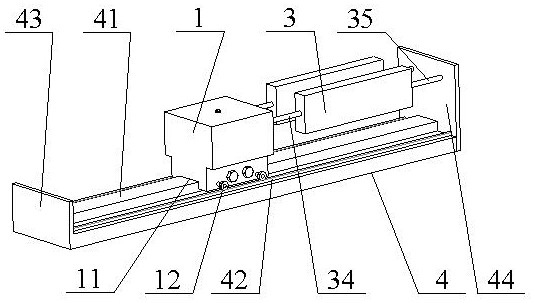

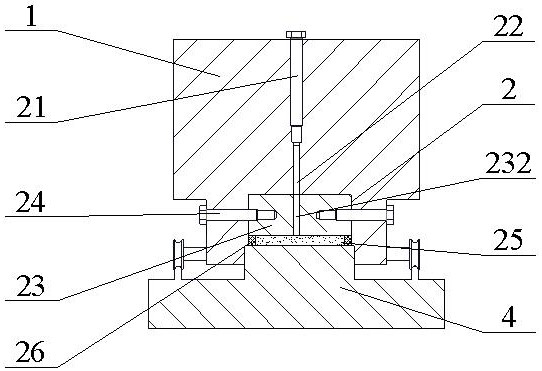

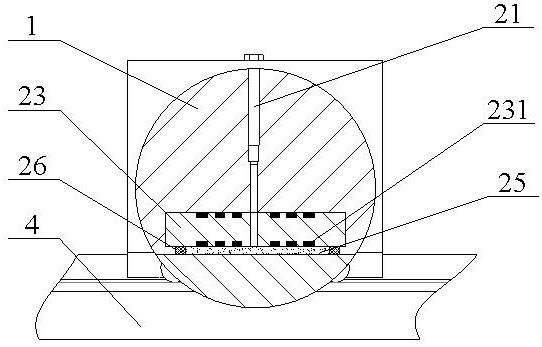

[0022] like Figure 1-5 As shown, the ATMD vibration damping device of the self-powered mass damping composite structure of the present invention includes a mass block 1, a magnetorheological fluid damping unit 2, two power generating units 3, and a sliding guide rail 4; the groove 11 of the mass block 1 It is embedded in the center boss 41 of the sliding guide rail, and plays a certain role in limiting the movement of the mass block 1; The mass block 1 is reciprocated along the guide rail while assisting the position limit; one end of the sliding guide rail 4 is provided with a first baffle 43, and the other end is provided with a second baffle 44; The ends are fixed horizontally above the second baffle 44 and the mass 1 .

[0023] The magnetorheological fluid damping unit 2 is placed inside the mass block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com