An epoxy resin composition suitable for fan-out wafer level packaging

A wafer-level packaging, epoxy resin technology, used in circuits, electrical solid devices, semiconductor devices, etc., can solve problems such as insufficient fluidity under high filling amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

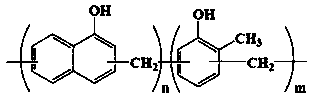

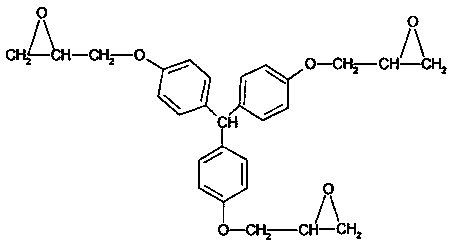

[0022] Embodiment 1, an epoxy resin composition suitable for fan-out wafer level packaging: its main components include epoxy resin, silicon micropowder, curing agent and flow aid; 89% of the total mass; the curing agent is formula [1], and the content of the curing agent accounts for 3% of the total mass of the epoxy resin composition; the epoxy resin is shown in the formula [3], and its content accounts for 6% of the total mass of the epoxy resin composition; the glidant is a methoxy-containing silicone resin, and its content accounts for 0.5% of the total mass of the epoxy resin composition. The epoxy resin composition also contains an appropriate amount of one or more of a catalyst, a coloring agent, a release agent, an ion trapping agent, a coupling agent, and a stress absorbing agent.

Embodiment 2

[0023] Embodiment 2, an epoxy resin composition suitable for fan-out wafer level packaging: its main components include epoxy resin, silicon micropowder, curing agent and flow aid; 90% of the total mass; the curing agent is formula [2], and the content of the curing agent accounts for 6% of the total mass of the epoxy resin composition; the epoxy resin is shown in formula [3], and its content accounts for 6% of the total mass of the epoxy resin composition; 2% of the total mass of the epoxy resin composition; the flow aid is a silicone resin containing methoxy groups, and its content accounts for 1% of the total mass of the epoxy resin composition. The epoxy resin composition also contains an appropriate amount of one or more of a catalyst, a coloring agent, a release agent, an ion trapping agent, a coupling agent, and a stress absorbing agent.

Embodiment 3

[0024] Embodiment 3, a kind of epoxy resin composition suitable for fan-out type wafer level packaging: its main component comprises epoxy resin, silicon micropowder, curing agent and flow aid; 92% of the total mass; the curing agent is formula [1] and formula [2], and the content of the curing agent accounts for 5% of the total mass of the epoxy resin composition, wherein the content of the formula [1] accounts for 5% of the epoxy resin composition 1% of the total mass, the content of formula [2] accounts for 4% of the total mass of the epoxy resin composition; the epoxy resin is shown in formula [3], and its content accounts for 2% of the total mass of the epoxy resin composition ; The glidant is a silicone resin containing methoxy, and its content accounts for 0.8% of the total mass of the epoxy resin composition. The epoxy resin composition also contains an appropriate amount of one or more of a catalyst, a coloring agent, a release agent, an ion trapping agent, a coupling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com