A kind of interface reinforced lightweight concrete and its preparation method

A light-weight concrete and interface-enhanced technology, applied in the field of interface-enhanced lightweight concrete and its preparation, can solve the problems of restricting the application and promotion of EPS concrete, increasing the price of EPS concrete, and weak interface bonding force of cement paste, etc., to meet the requirements of Construction quality requirements, improved bonding strength, and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An interface reinforced lightweight concrete, which consists of the following components in parts by weight: 150 parts of cement, 43 parts of water, 0.4 parts of water reducing agent, 0.1 part of cellulose ether, silicone emulsion coupling modified expanded polystyrene (Modified EPS) 12 parts.

[0023] The preparation method of the above interface reinforced lightweight concrete, the specific steps are as follows:

[0024] 1. Preparation of silicone emulsion: silicone emulsion is an emulsion obtained by mixing and copolymerizing neutral silica sol aqueous solution, allyl polyether, allyl siloxane, and butyl methacrylate. The specific preparation process is as follows: neutral silicon Sol aqueous solution, allyl polyether aqueous solution, allyl siloxane aqueous solution, and pure butyl methacrylate are mixed in a volume ratio of 1:0.05:0.05:1, and a blend is obtained after ultrasonic dispersion; then, to the blend Add 0.1g / L hydrogen peroxide and 10% polyvinyl alcohol ...

Embodiment 2-10

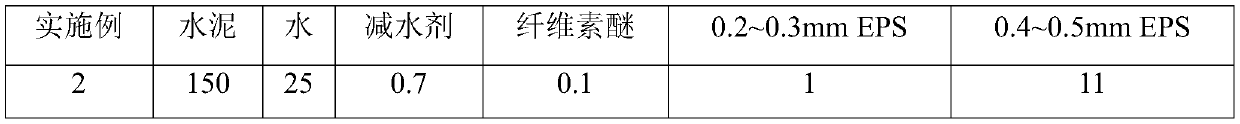

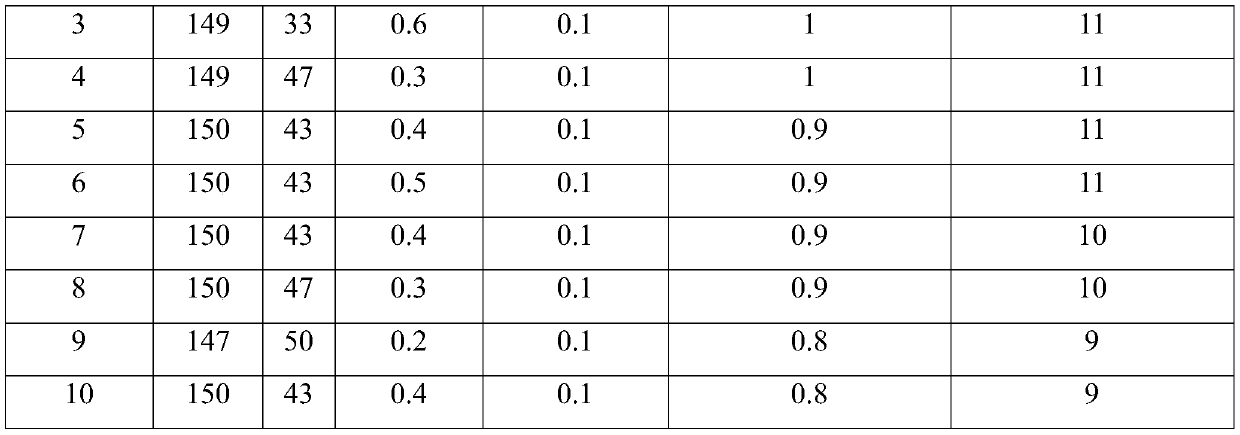

[0030] The components in Examples 2-10 are shown in Table 1 in parts by weight, and the specific raw materials and preparation methods are the same as those in Example 1.

[0031] Table 1

[0032]

[0033]

[0034] The bulk density of interface reinforced lightweight concrete prepared in Example 2-10 is 800-1200kg / m 3 , 7d strength up to 10-20MPa. Among them, the water content should not be too little. A proper amount of water is beneficial to concrete forming and has a certain influence on the concrete strength. The more water is added, the lower the concrete strength is, preferably 35-45 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com