Quick die replacing device for prefabricated member hole and using method of quick die replacing device

A prefabricated and fast technology, applied in the direction of mold separation device, mold fixing device, manufacturing tool, etc., can solve problems such as unfavorable rapid mold change and production cost saving, inability to achieve rapid disassembly and assembly stability at the same time, cumbersome fixing of side molds, etc. , to achieve the effect of saving processing steps, facilitating the cleaning process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

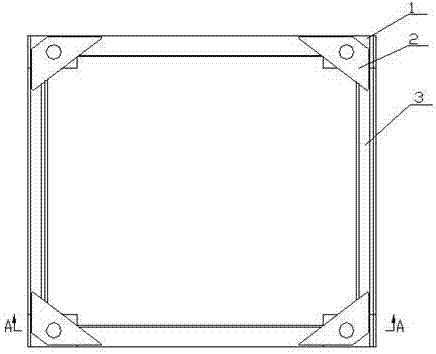

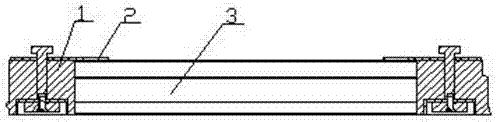

[0025] As shown in the attached figure: a quick mold change device for the opening of prefabricated parts, including the rubber magnetic box corner connector 1, the pressure plate 2 and the side mold 3, the rubber magnetic box corner connector 1 and the side mold 3 are alternately connected end to end to form a closed hole Flat mold structure, the pressing plate 2 is installed above the corner connector 1 of the rubber magnetic box, and the two ends of the pressing plate 2 are pressed tightly above the two adjacent side molds 3 .

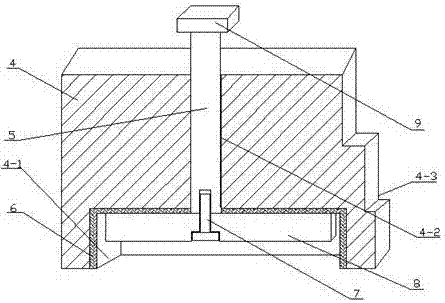

[0026] The rubber magnetic box corner joint 1 includes a rubber piece 4 with two connecting sides and a corner mechanism composed of the connecting sides, a magnetic box body 6 located at the bottom of the rubber piece 4, which is passed through the rubber piece 4 and can be moved along the rubber piece. 4 Connecting piece 5 that moves up and down in the height direction. The box body 6 is provided with an opening away from the end of the rubber piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com