Thermostatic impregnation device used for laboratory

A technology of impregnation equipment and laboratory, applied in the field of research on the preparation of supported catalysts, can solve the problems of affecting the experimental effect, unstable constant temperature conditions, and inability of the impregnating liquid to fully contact the catalyst, so as to achieve the effect of ensuring the experimental effect and improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

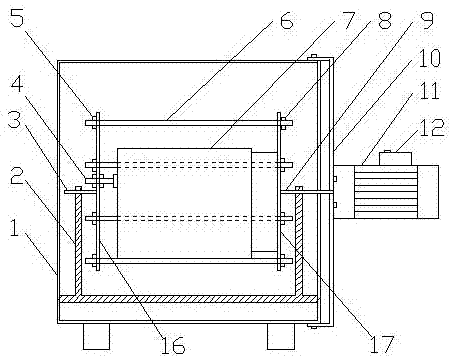

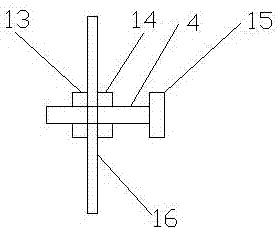

[0013] The present invention will be described in further detail in conjunction with the accompanying drawings, the left rotating shaft 3 and the right rotating shaft 9 fixed at both ends of the drum are rotatably connected to the support 2, the rotating drum and the support 2 are all arranged in the constant temperature oven 1, and the support 2 is fixedly connected to the constant temperature oven 1. At the bottom, the right rotating shaft 9 passes through the side wall of the constant temperature oven and is rotatably connected to the side wall of the constant temperature oven. The right end of the right rotating shaft 9 is fixedly connected to the output shaft of the motor 12, and the motor 12 is fixedly connected to the On the side wall of the constant temperature oven. The motor 11 is a speed-regulating motor, and the speed governor 12 is used to control the speed of the motor.

[0014] In a further preferred embodiment, the drum is composed of a left baffle 16, a right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com