Heart valve prosthesis with clamping devices

A clamping device and heart valve technology, which is applied in the field of medical devices and can solve problems such as unstable prosthesis fixation and paravalvular leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

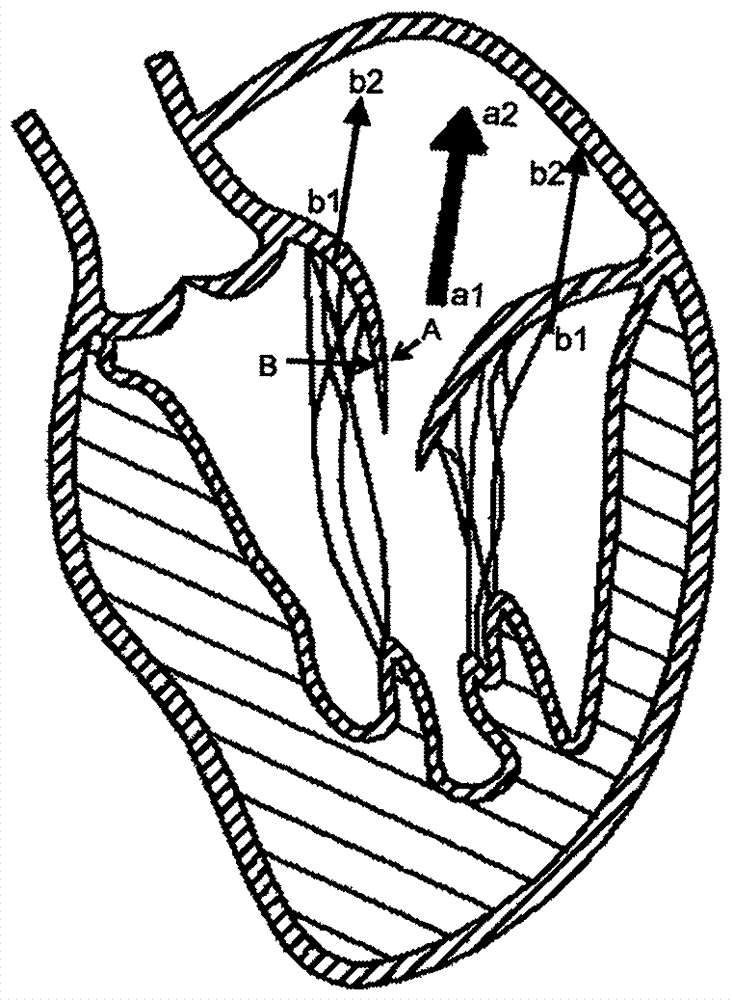

[0058] When the heart valve prosthesis is used to treat mitral valve disease, Figure 1a A schematic cross-sectional view of the left ventricle is shown, wherein, a1-a2 is the central axis of the blood flow direction of the valve sewing section, also known as the axis line of the valve sewing section, and b1-b2 is the clamping The central axis of the blood flow direction of the device, a1-a2 is parallel to b1-b2, plane A is the closing surface of the native mitral valve leaflet, and plane B is the opposite side of the closing surface of the native mitral valve leaflet, The radial direction of the cross-section of the valve sewing section is called the radial direction of the valve sewing section, the circumferential surface of the valve sewing section close to the axis line is the inner surface, and the valve sewing section The circumferential surface of the section away from the axis is the outer surface.

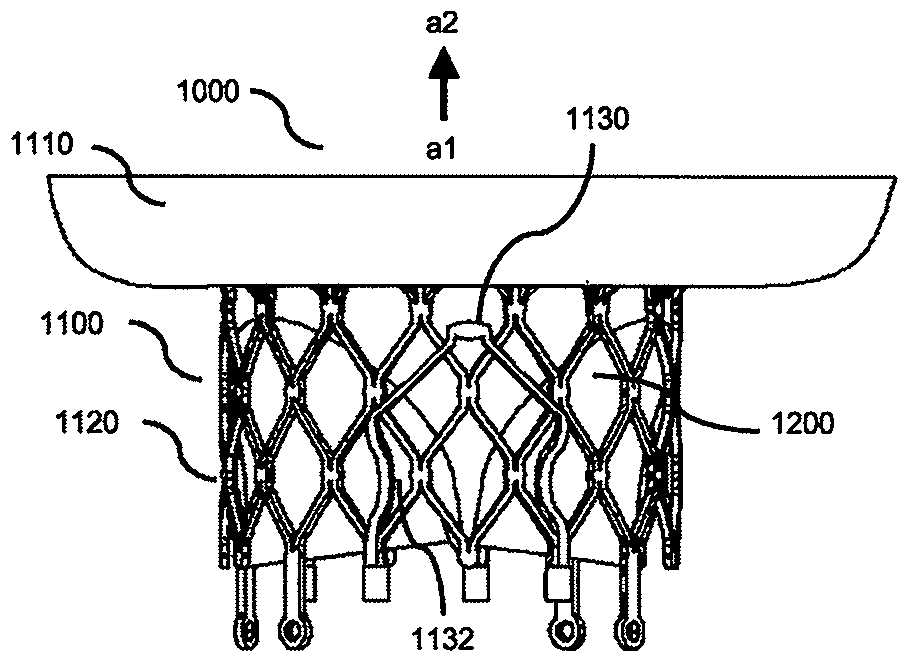

[0059] In one embodiment of the present invention, as Figure 1b As...

specific Embodiment 2

[0062] In order to illustrate the working principle of the present invention better, the release process of the artificial valve prosthesis of the present invention will be described step by step below:

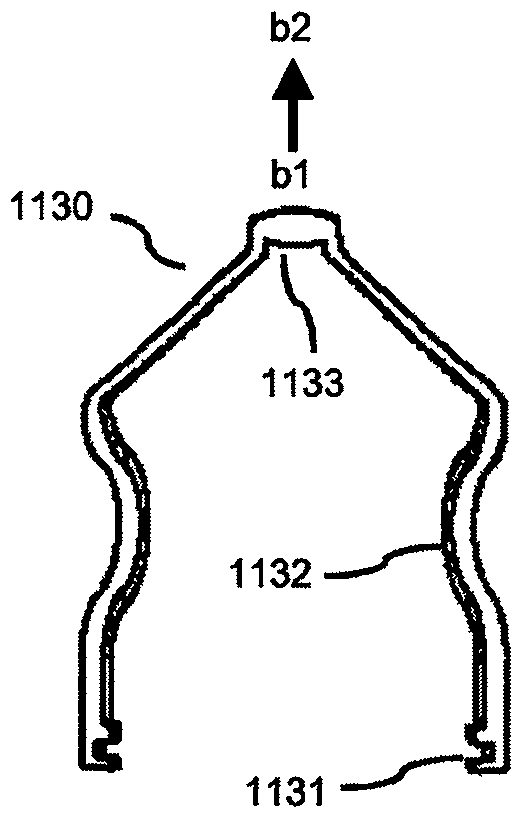

[0063] Such as Figure 2a As shown, the heart valve prosthesis is accessed through the delivery system 2300 from the apex when the heart valve prosthesis is used to treat mitral valve disease. Such as Figure 2b As shown, the delivery system 2300 includes a handle 2310, an outer sheath 2320 and an inner sheath 2330. By operating the handle 2310, the clamping device 1130 placed in the outer sheath 2320 is released. In an embodiment, the number of the clamping device 1130 is one, and at this time, the stent and the artificial valve are still partially or completely compressed in the inner sheath 2330 . Such as Figure 2c-2d As shown, the free end 1133 of the clamping device 1130 opens away from the inside of the bracket to the outside of the bracket, forming an angle α. Due ...

specific Embodiment 3

[0066] In one embodiment of the present invention, as Figures 5a-5b As shown, a heart valve prosthesis 1000 with a clamping device includes a stent 1100 and an artificial valve 1200. The stent 1100 is made of shape memory alloy and includes an atrium segment 1110, a valve sewing segment 1120 and two clamping device 1130, the artificial valve 1200 is fixedly connected to the valve sewing section 1120, and the axis a1-a2 of the valve sewing section 1120 is as follows Figure 5a As shown, the atrium segment 1110 is integrally cut with the valve sewing segment 1120, the proximal end of the atrium segment 1110 is connected to the distal end of the valve sewing segment 1120, and the atrium segment 1110 is sewn Manufactured with a polymer or animal-derived material (not shown) that can reduce or prevent blood flow through, the atrial segment 1110 is flared to the outside of the valve sewn segment, and the atrial segment 1110 is sewn on the valve The projected area in the radial dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com