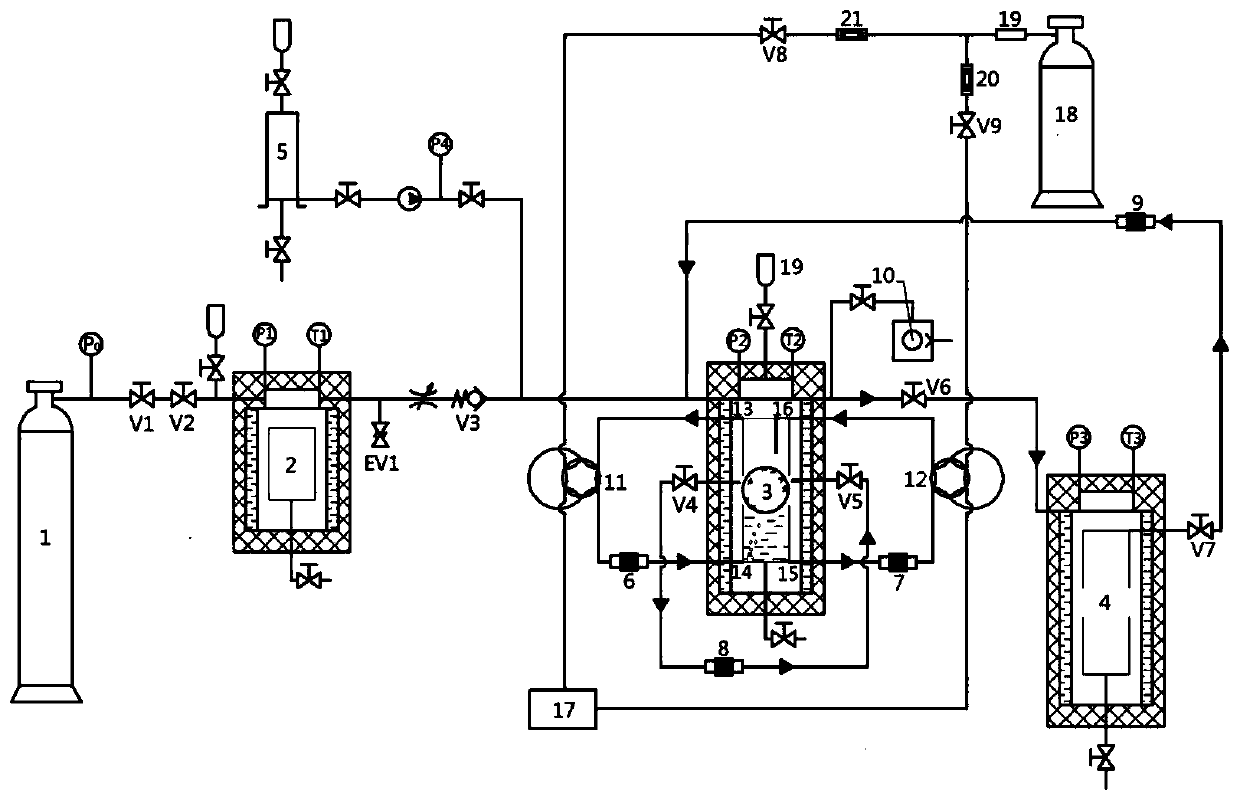

A continuous flow high temperature and high pressure experimental device

A high temperature and high pressure, experimental device technology, applied in the investigation phase/state change and other directions, can solve the problems of short equilibration time, long equilibration time, and reduced equilibration time, and achieve accurate equilibrium temperature and equilibrium pressure, accurate, reliable and convenient measurement process. The effect of data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Phase Equilibrium Data Determination:

[0051] 1. Open the high and low temperature circulation tank, set the temperature required for the operation of the balance tank 3; turn on the vacuum pump, vacuum the buffer tank 2, balance tank 3 and each pipeline to the ultimate pressure, and use the vacuum to suck 20ml of ethyl butyrate.

[0052] 2. Put a certain amount of CO 2 The gas is extracted from the gas cylinder 1, enters the buffer tank 2 through the valve V1 and the valve V2 in turn, cools down to -20°C, and then heats up to 30°C, the fluid in the carrier gas tank 2 is rapidly increased to 40MPa, and the high-pressure fluid passes through the one-way The valve V3 is sent to the phase balance tank 3 and mixed with ethyl butyrate.

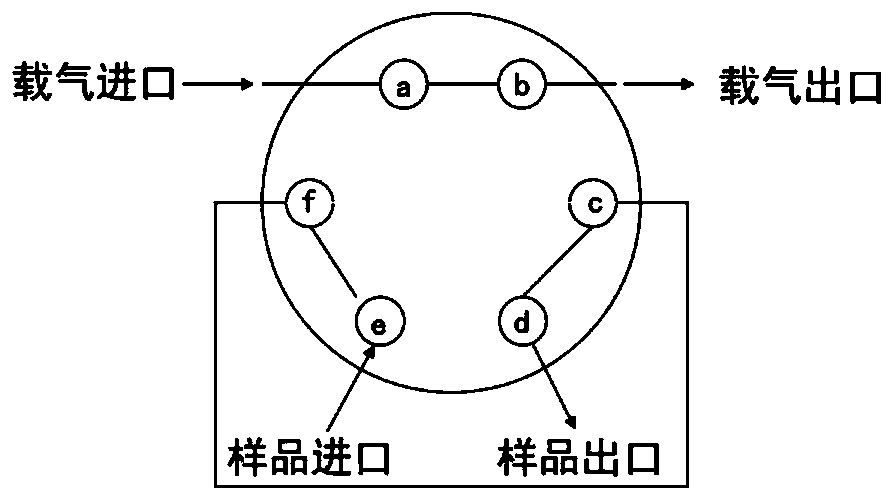

[0053] 3. Turn on the non-leakage pumps 6 and 7, and the circulating flow rate is 0.5ml / min~3ml / min, respectively to carry out forced circulation of the vapor-liquid two phases.

[0054] 4. When the pressure and temperature in the balance...

Embodiment 2

[0057] Phase Equilibrium Data Determination:

[0058] 1. Open the high and low temperature circulation tank, set the temperature required for the operation of the balance tank 3; turn on the vacuum pump, vacuum the buffer tank 2, balance tank 3 and each pipeline to the ultimate pressure, and use the vacuum to suck 25ml of isobutyl acetate.

[0059] 2. Put a certain amount of CO 2 The gas is drawn from the gas cylinder 1, enters the buffer tank 2 through the valve V1 and the valve V2 in turn, cools down to -20°C, and then heats up to 70°C, the fluid in the carrier gas tank 2 is rapidly boosted to 70MPa, and the high-pressure fluid passes through the one-way valve V3 is sent to phase balance tank 3 and mixed with ethyl butyrate.

[0060] 3. Turn on the non-leakage pumps 6 and 7, and the circulation flow rate is 1ml / min~3.5ml / min, and the vapor-liquid two-phase is forced to circulate respectively.

[0061] 4. When the pressure and temperature in the balance kettle 3 are stable ...

Embodiment 3

[0064] Subsupercritical extraction experiment:

[0065] 1. Open the high and low temperature circulation tank, set the temperature required for the operation of the balance tank 3; turn on the vacuum pump, vacuum the buffer tank 2, balance tank 3 and each pipeline to the ultimate pressure, and use the vacuum to suck 30ml of engine oil.

[0066] 2. Put a certain amount of CO 2 The gas is drawn from the gas cylinder 1, enters the buffer tank 2 through the valve V1 and the valve V2 in turn, cools down to -30°C, and then heats up to 80°C, the fluid in the carrier gas tank 2 is rapidly boosted to 95MPa, and the high-pressure fluid passes through the check valve V3 is sent to phase balance kettle 3 and mixed with engine oil.

[0067] 3. Turn on the non-leakage pump 9, the circulation flow rate is 1ml / min-3.5ml / min, and the mixed system is forced to circulate, and the time for each intermittent extraction is 2h.

[0068] 4. After the extraction is completed, the extracted material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com