Concrete tower mounting levelling method

A concrete and tower technology, applied in the direction of towers, building types, buildings, etc., can solve the problems of tower leveling difficulty and high cost, and achieve the effect of short installation time, low cost and shortened installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

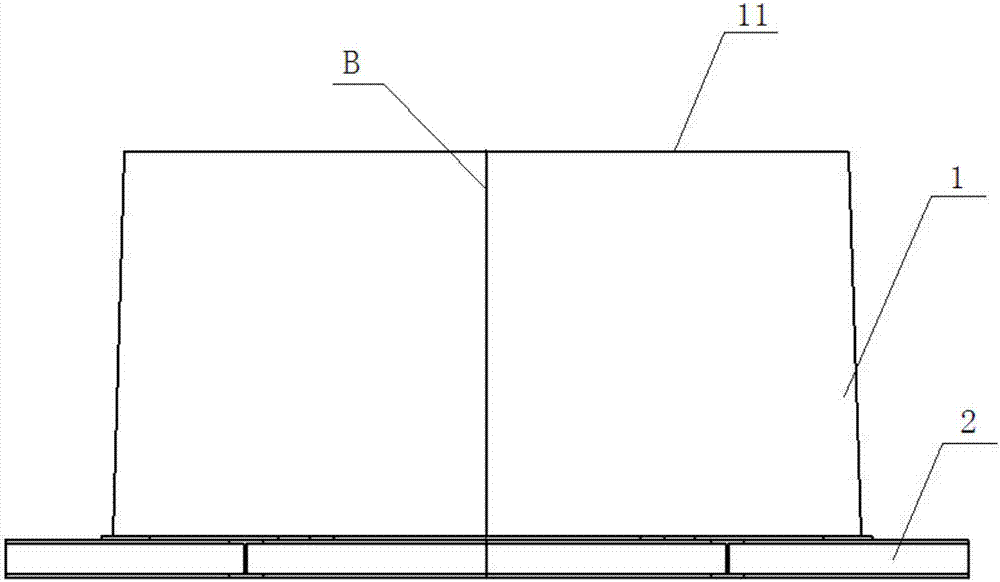

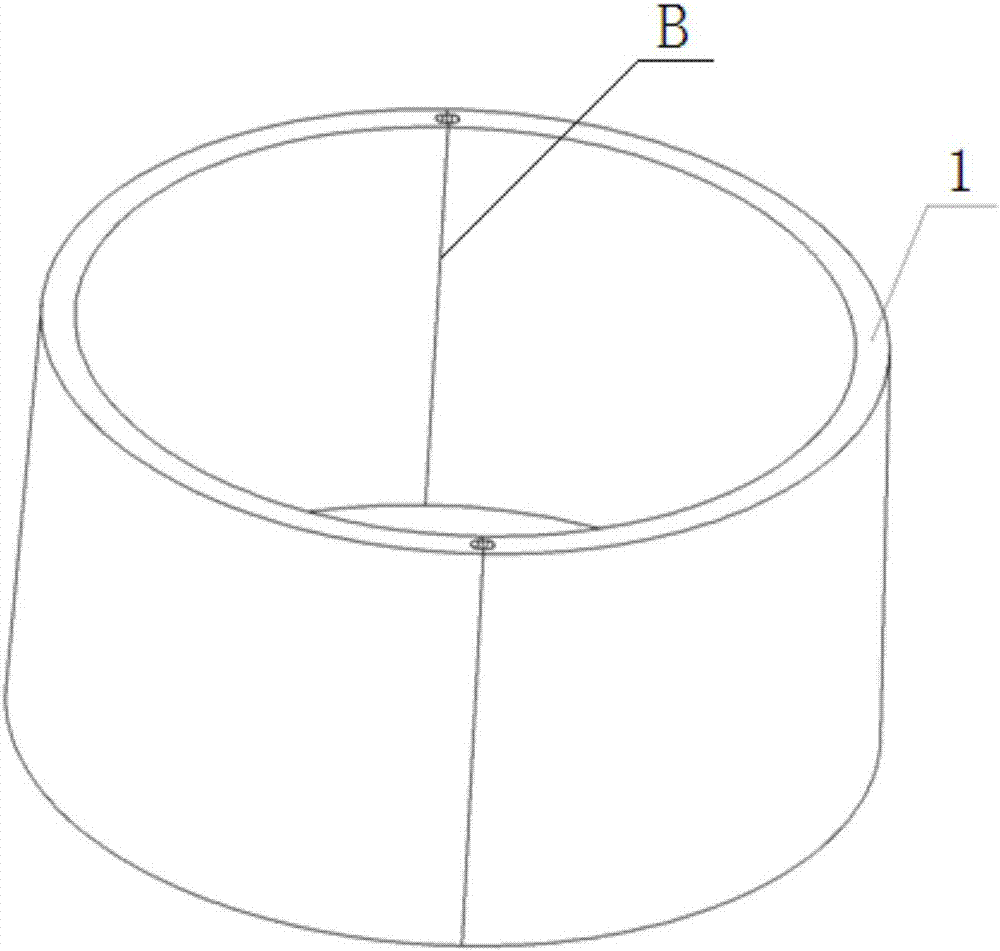

[0035] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

[0036] According to the method provided by the invention, the parallelism of the upper and lower sides of the concrete prefabricated parts can be improved; the verticality of the tower frame on site can also be corrected.

[0037] The pre-leveling operation before installation refers to placing the concrete ring or sheet ring on the leveling device, and using a laser leveling instrument (or laser level) to measure the flatness of the upper plane of the concrete ring, and the measuring point can be set as required Divide into equal parts, such as 6, 8, 12 or more, mark and record errors. Then use different thicknesses of glass fiber cloth (cut the shape and size in advance), and use epoxy resin to bond layer by layer;

[0038] After waiting for solidification, the levelness can be tested again until the design requirements are met.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com