Method for improving flame retardance of fraxinus mandshurica wood

A flame-retardant, wood-based technology, applied in the field of wood product processing, can solve the problems of resin-type flame retardants such as poor effect, reduced effect, and easy moisture absorption, so as to speed up impregnation speed and impregnation amount, and improve penetration The effect of improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

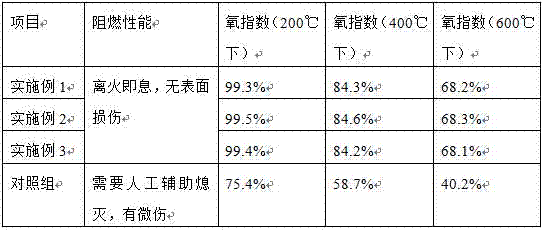

Examples

Embodiment 1

[0016] A method for improving the flame retardancy of Fraxinus mandshurica wood. The flame retardant used is made of the following components in terms of mass percentage: tricresyl phosphate accounts for 12.5%, tetrachlorophthalic anhydride accounts for 11.0%, melamine-formaldehyde Resin accounts for 7.5%, epoxidized polyamide resin accounts for 7.0%, ethylenediamine accounts for 6.2%, dialkyl-p-phenylenediamine accounts for 5.0%, pentaerythritol accounts for 4.5%, 2,6 di-tert-butyl-4-methylphenol Accounting for 2.8%, dioctadecylmethylamino quaternary ammonium salt accounts for 2.5%, and the remainder is water, and its technological method comprises the following steps:

[0017] (1) Put the ash wood in an oven preheated at 100°C, and dry it until the quality is constant. After drying, take out the wood, then put the wood in a pressure tank, and vacuumize it for 15 minutes, with a vacuum degree of 50KPa , inject the prepared flame retardant into the pressure tank, completely so...

Embodiment 2

[0025] A method for improving the flame retardancy of Fraxinus mandshurica wood. The flame retardant used is made of the following components in terms of mass percentage: tricresyl phosphate accounts for 12.7%, tetrachlorophthalic anhydride accounts for 11.5%, melamine-formaldehyde Resin accounts for 7.8%, epoxidized polyamide resin accounts for 7.2%, ethylenediamine accounts for 6.3%, dialkyl-p-phenylenediamine accounts for 5.3%, pentaerythritol accounts for 4.7%, 2,6 di-tert-butyl-4-methylphenol Account for 2.9%, dioctadecylmethylamino quaternary ammonium salt accounts for 2.7%, and the remainder is water, and its process method comprises the following steps:

[0026] (1) Put the ash wood in an oven preheated at 102°C, and dry it until the quality is constant. After baking, take out the wood, then put the wood into a pressure tank, and vacuumize it for 17 minutes, with a vacuum degree of 55KPa , inject the prepared flame retardant into the pressure tank, completely soak the ...

Embodiment 3

[0034]A method for improving the flame retardancy of Fraxinus mandshurica wood. The flame retardant used is made of the following components in terms of mass percentage: tricresyl phosphate accounts for 13.0%, tetrachlorophthalic anhydride accounts for 12.0%, melamine-formaldehyde Resin accounts for 8.0%, epoxidized polyamide resin accounts for 7.5%, ethylenediamine accounts for 6.5%, dialkyl-p-phenylenediamine accounts for 5.5%, pentaerythritol accounts for 5.0%, 2,6 di-tert-butyl-4-methylphenol Accounting for 3.0%, dioctadecylmethylamino quaternary ammonium salt accounts for 3.0%, the remainder is water, and its process method comprises the following steps:

[0035] (1) Put the ash wood in an oven preheated at 105°C, and dry it until the quality is constant. After baking, take out the wood, then put the wood in a pressure tank, and vacuumize it for 20 minutes, with a vacuum degree of 60KPa , inject the prepared flame retardant into the pressure tank, completely soak the wood...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com