Current blocking layer and light emitting diode chip manufacturing method

A technology of current blocking layer and manufacturing method, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., and can solve the problems of high voltage and low antistatic ability of light-emitting diode chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

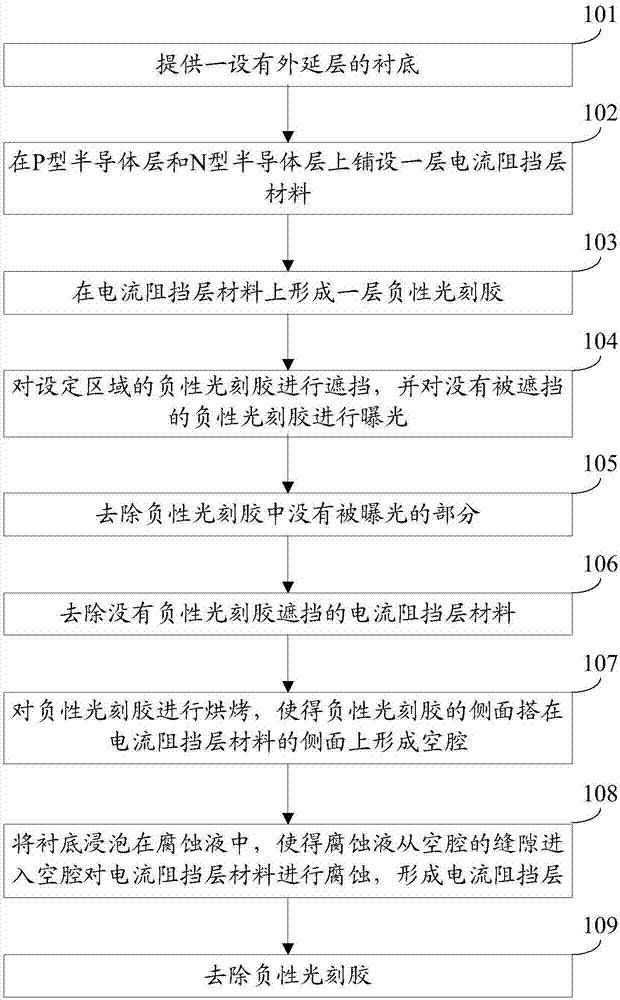

[0042] The embodiment of the present invention provides a method for fabricating a current blocking layer, see figure 1 , the production method includes:

[0043] Step 101: Provide a substrate with an epitaxial layer.

[0044] Figure 2a It is a schematic diagram of a partial structure of the LED chip after step 101 is executed. Among them, 10 is the substrate with the epitaxial layer.

[0045] In this embodiment, the epitaxial layer includes an N-type semiconductor layer, a light-emitting layer, and a P-type semiconductor layer stacked on the substrate in sequence. grooves in the semiconductor layer.

[0046] Specifically, the substrate may be a sapphire substrate or a silicon substrate. The N-type semiconductor layer may be an N-type GaN layer, and the P-type semiconductor layer may be a P-type GaN layer. The light-emitting layer may include multiple InGaN layers and multiple GaN layers, and the multiple InGaN layers and multiple GaN layers are alternately stacked.

...

Embodiment 2

[0098] An embodiment of the present invention provides a method for manufacturing a current blocking layer, which is a specific implementation of the method provided in Embodiment 1, see image 3 , the production method includes:

[0099] Step 201: Provide a substrate with an epitaxial layer.

[0100] Step 202: Deposit a layer of current blocking layer material with a thickness of 2000 angstroms on the P-type semiconductor layer and the N-type semiconductor layer.

[0101] Step 203: Coating an adhesion promoter on the material of the current blocking layer.

[0102] Step 204: Coating a negative photoresist with a thickness of 2 microns on the tackifier.

[0103] Step 205: Exposing the negative photoresist on the current blocking layer with an exposure energy of 90mj / cm 2 .

[0104] Step 206: Use a developer solution with a concentration of 2.38% to remove the part of the negative photoresist that has not been exposed, and the angle formed between the side and the bottom of...

Embodiment 3

[0111] An embodiment of the present invention provides a method for manufacturing a light emitting diode chip, see Figure 4 , the production method includes:

[0112] Step 301: Provide a substrate with an epitaxial layer.

[0113] Figure 5a It is a schematic structural diagram of the LED chip after step 301 is executed. Wherein, 10 is a substrate provided with an epitaxial layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com