Method for preparing high-energy-density supercapacitor by taking oxide as template

A technology of energy density and capacitor, which is applied in the field of preparing supercapacitors with high energy density. It can solve the problems of inability to produce in large quantities, low voltage window, and low sample purity, so as to improve the voltage window and energy density, inhibit electrolysis of water, and react Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method step of the present invention is:

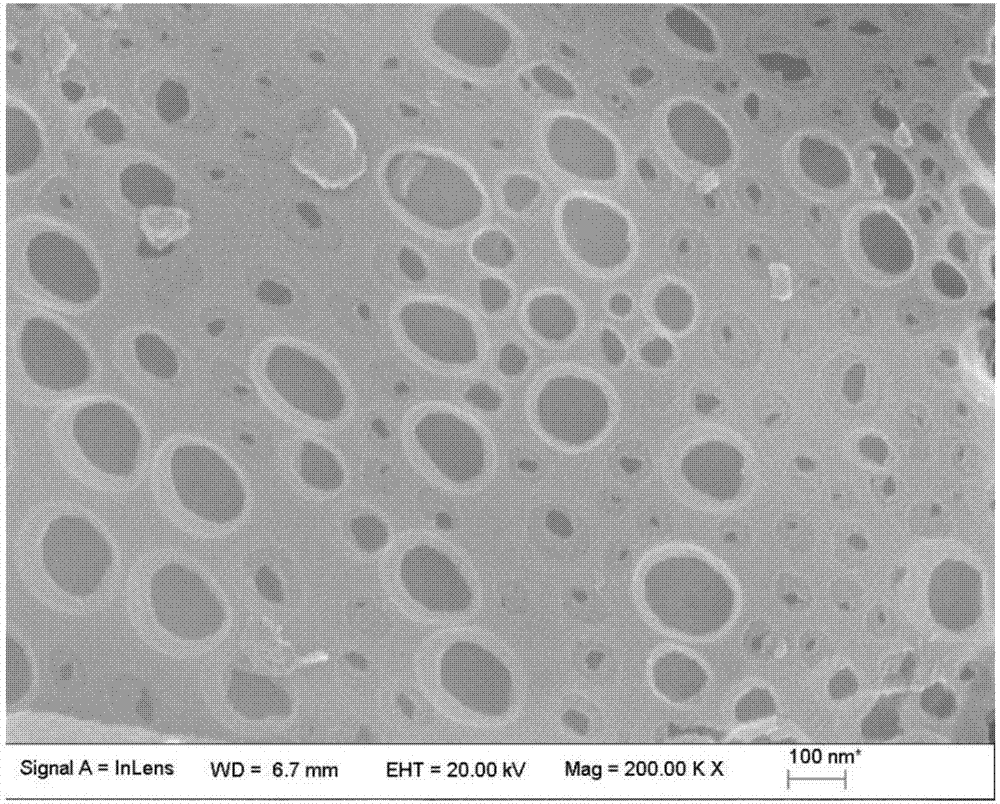

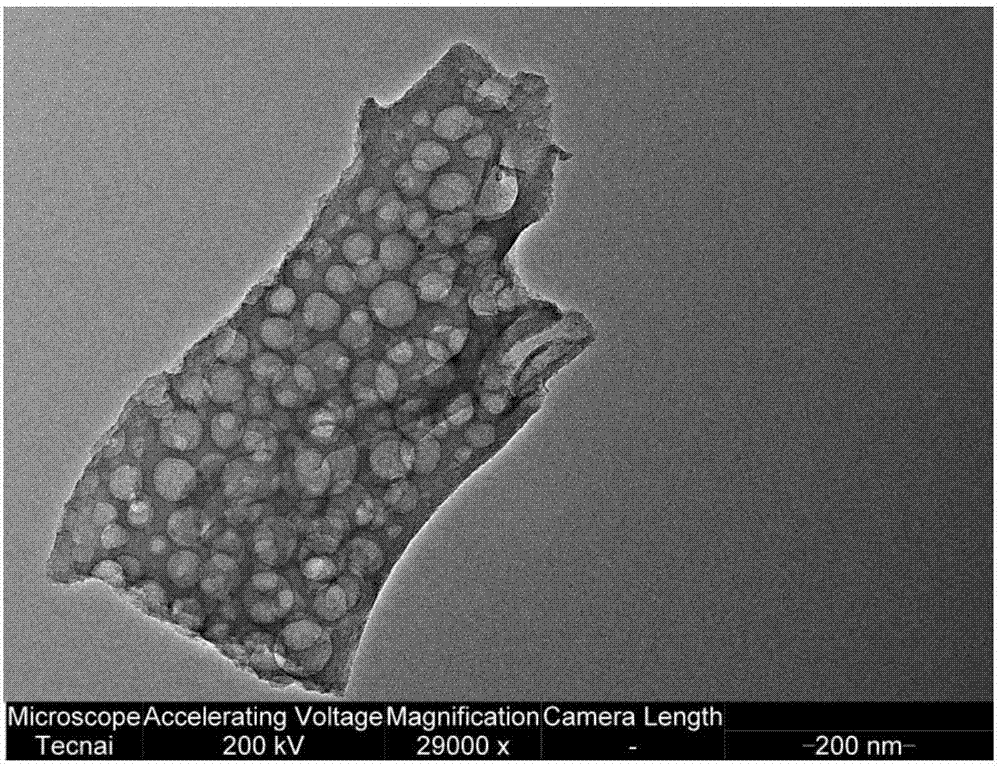

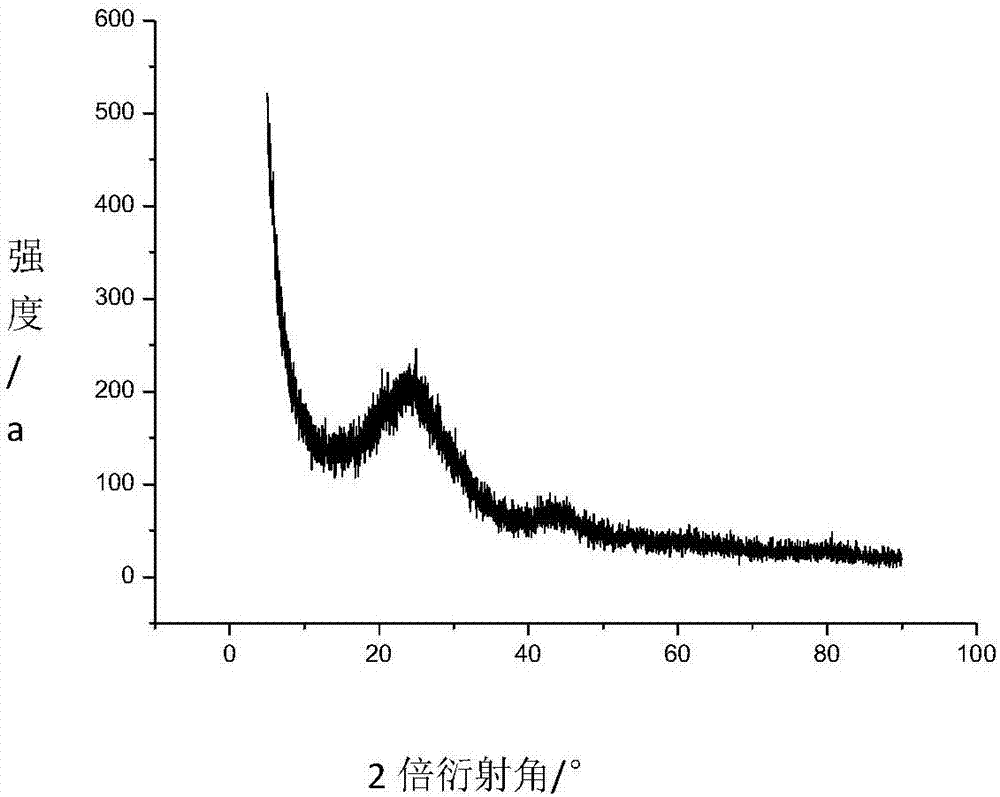

[0037] 1. Weigh 2g of zinc oxide, 2.0g of polyvinylidene chloride, and 1.0g of melamine, mix them in nitrogen-nitrogen dimethylacetamide, ball mill for 4 hours, and dry in an oven at 70°C to obtain a precursor. Calcined at a high temperature of 700° C. for 2 hours at a temperature increase rate of 10° C. per minute under the protection of argon, and obtained a carbon material by acid washing.

[0038] 2. Prepare the material into an electrode sheet, and assemble it into a button capacitor in a neutral electrolyte lithium sulfate for testing.

[0039] The selected pickling is 20% sulfuric acid.

[0040] The concentration of lithium sulfate is 1 mole per liter.

Embodiment 2

[0042] 1. Weigh 2g of magnesium oxide, 2.0g of polyvinylidene chloride, and 1.0g of melamine, mix them in nitrogen-nitrogen dimethylacetamide, ball mill them for 4 hours, and dry them in a 70° oven to obtain a precursor. Calcined at a high temperature of 700° C. for 2 hours under the protection of argon at a heating rate of 10° C. per minute, and washed with sulfuric acid to obtain a carbon material.

[0043] 2. The material is prepared into an electrode sheet, and assembled into a button capacitor in a neutral electrolyte lithium sulfate (concentration of 1 mole per liter) for testing.

Embodiment 3

[0045] Except the usage amount of the substances participating in the reaction, the template is changed to zinc oxide, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com