Unit coordinated control method and system based on boiler dynamic differential feedforward instruction

A differential feed-forward and coordinated control technology, applied in the general control system, control/regulation system, adaptive control, etc., can solve the problem of affecting the accuracy of boiler dynamic differential feed-forward command calculation, violating the basic principle of unit energy balance, Boiler combustion rate overshoot and other problems, to increase flexibility, overcome overshoot, improve the effect of response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

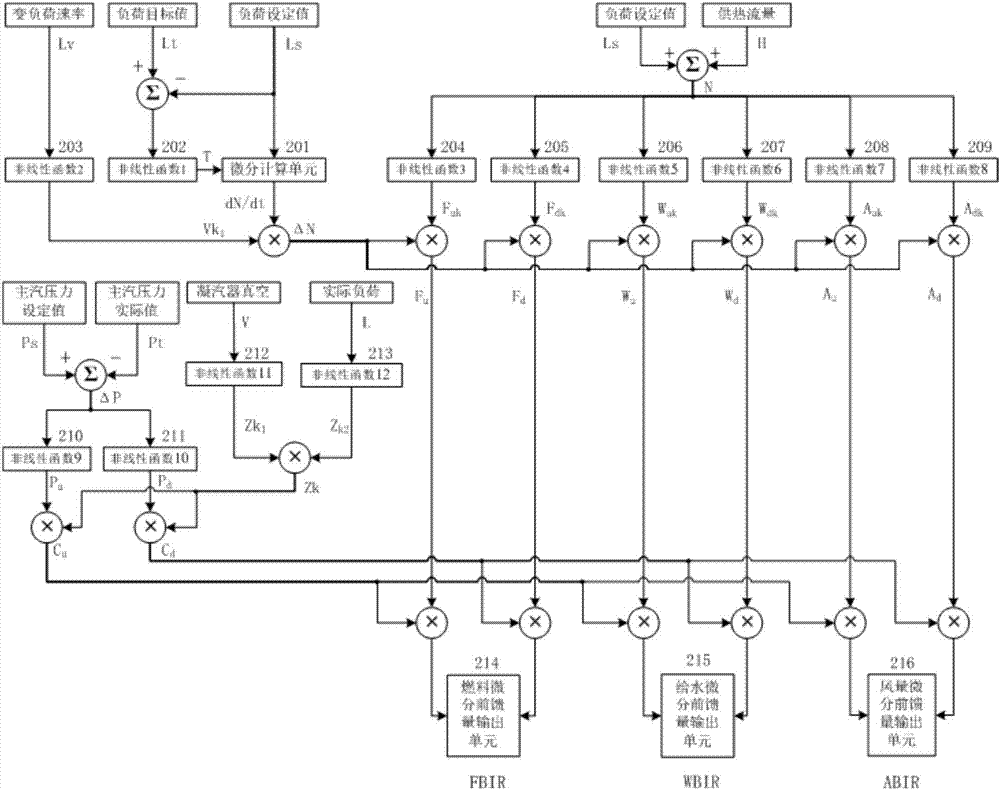

[0061] The present invention will be further described below in conjunction with the accompanying drawings.

[0062] like figure 1 , the unit coordinated control method based on the boiler dynamic differential feedforward command of this embodiment includes the following steps:

[0063] (1) After the difference between the load target value Lt and the load set value Ls is calculated by the nonlinear function 1, the inertial delay time T of the differential calculation unit is obtained, and then the calculation formula Ts / (1+Ts) of the differential calculation unit is determined;

[0064] (2) Calculate the load set value Ls through the differential calculation unit to obtain the instantaneous differential component dN / dt of the load set value, and the calculation relationship is dN / dt=[Ts / (1+Ts)]·Ls;

[0065] (3) Use the nonlinear function 2 to calculate the variable load rate, and obtain the instantaneous differential correction coefficient Vk of the load set value 1 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com