Device and method used for measuring axial bolt relaxation in consideration of joint surface characteristics

A joint surface and bolt technology, which is used to measure the direction of torque/torsional force during tightening, can solve the problems of unmeasurable contact surface changes, complex structure, and low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

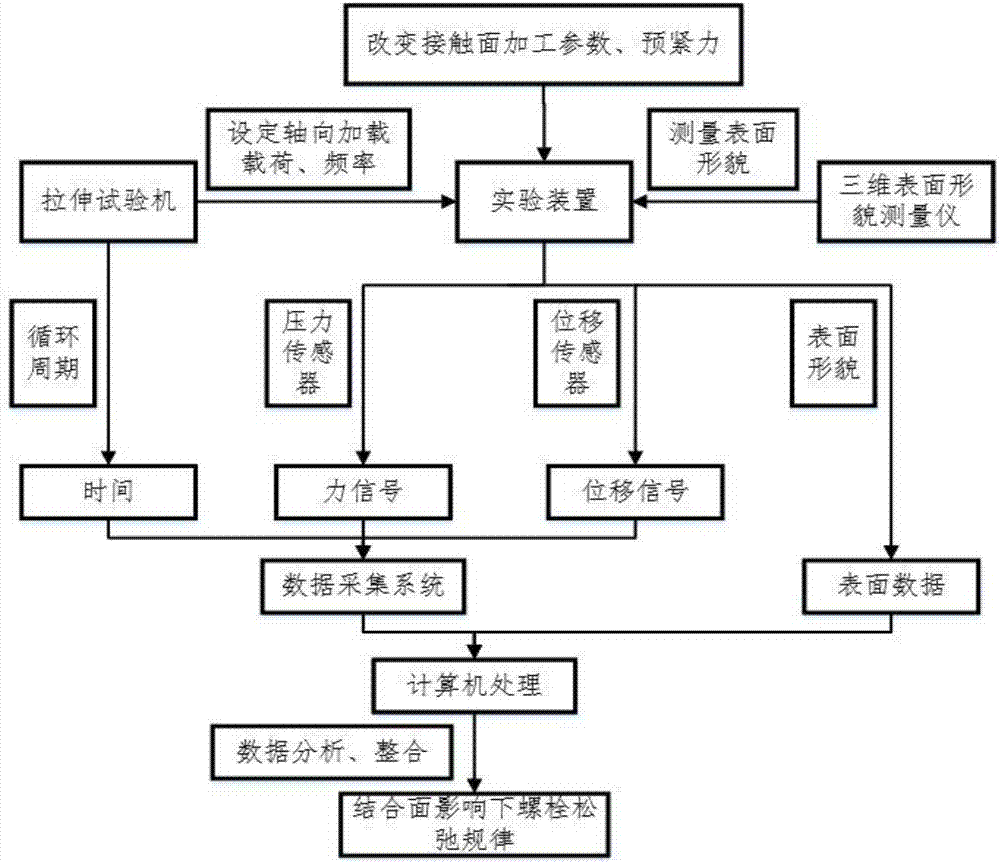

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

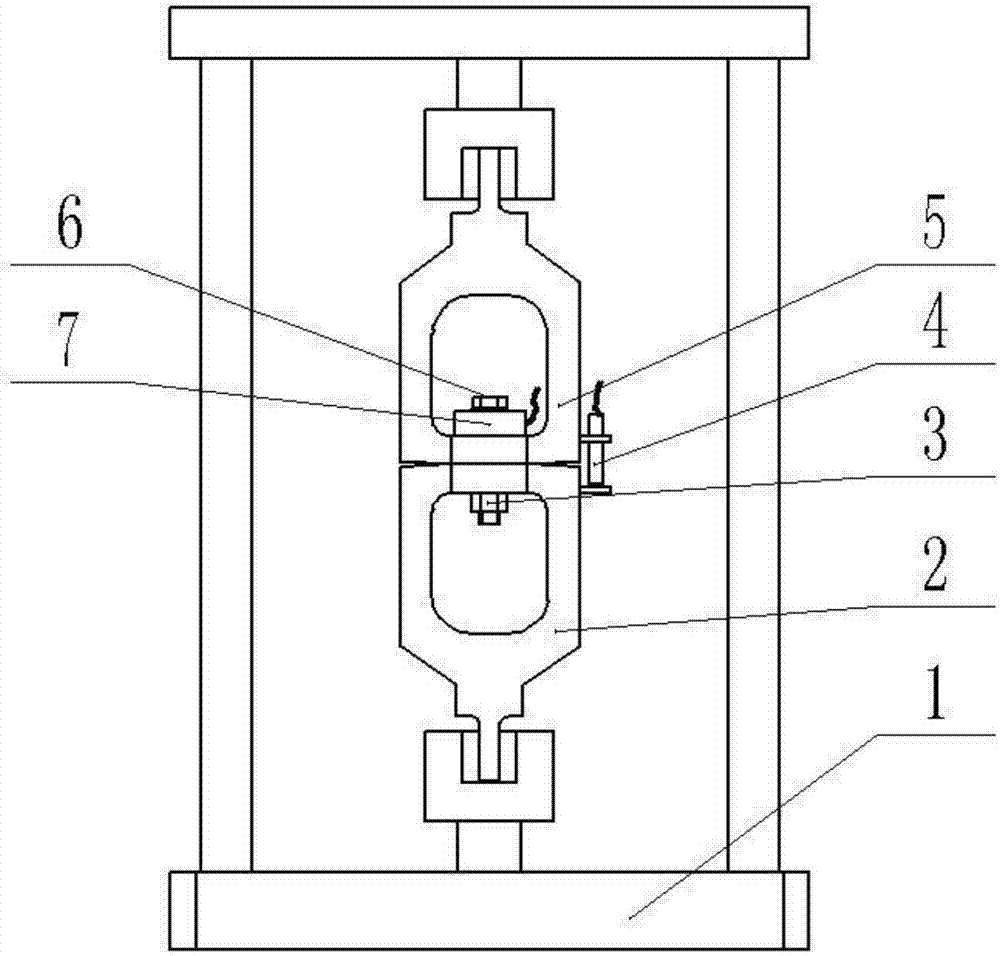

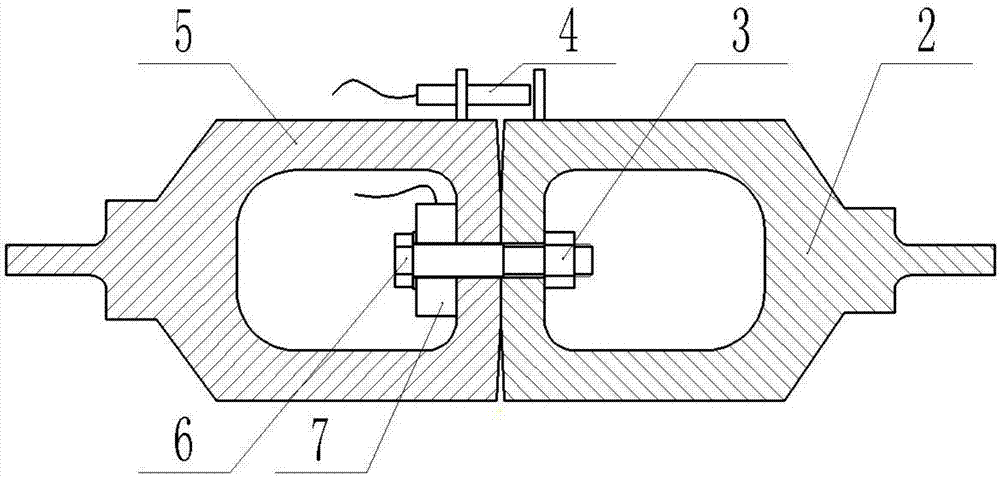

[0034]Step 1: Scan the contact area of the upper connector 2 and the lower connector 5 with different processing quality through a three-dimensional surface topography measuring instrument and establish a corresponding database, including 3D topography, three-dimensional coordinates, surface roughness, and waviness and other parameters as the initial reference value of the contact surface features. Start the tensile testing machine 1 for preheating; the pressure sensor 7, digital amplifier, data acquisition card and computer are connected in sequence, and the initial value is set to zero by software setting; the pressure sensor 7 is worn on the screw rod 6; The upper connecting piece 5 and the lower connecting piece 2 under the surface quality are connected by the screw rod 6 and the nut 3, so that the pressure sensor 7 forms a series connection between the screw rod 6 and the upper connecting piece 5; the different torques of the torque wrench are controlled to control the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com