Torsion spring driven shear hinge ring rib type deployable antenna mechanism

A torsion spring and antenna technology, which is applied in directions such as antennas, antenna supports/installation devices suitable for movable objects, etc., can solve the problems of complex deployable antenna mechanisms, poor rigidity and strength, and low reliability, and saves transmission. The effect of space, weight reduction, and large folding ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

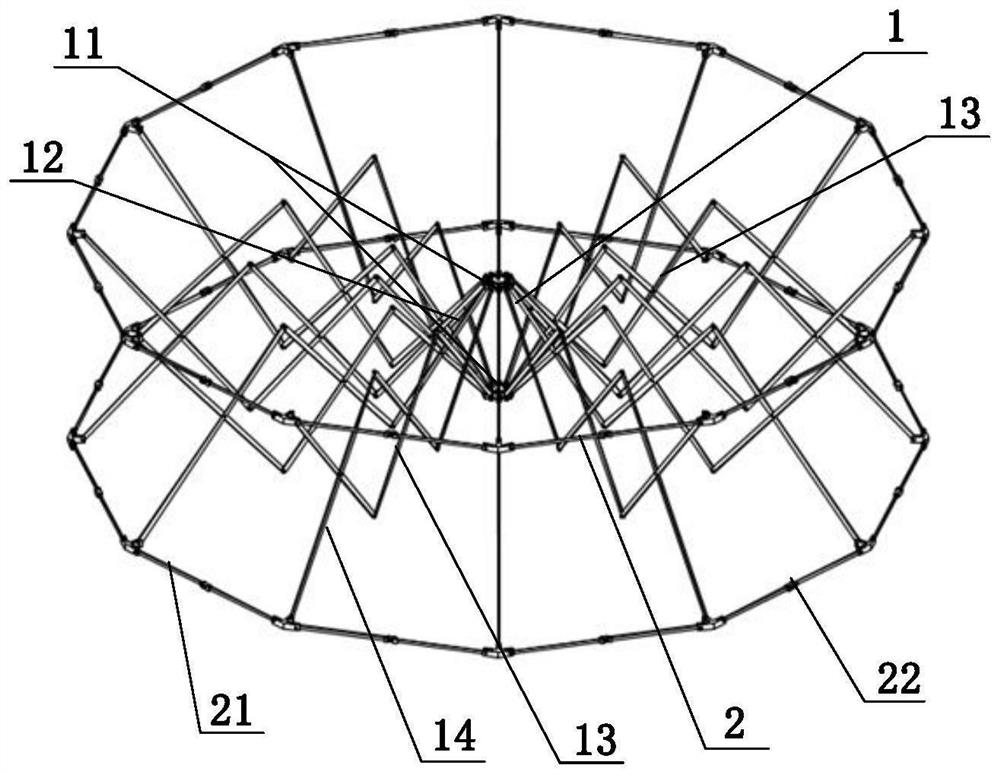

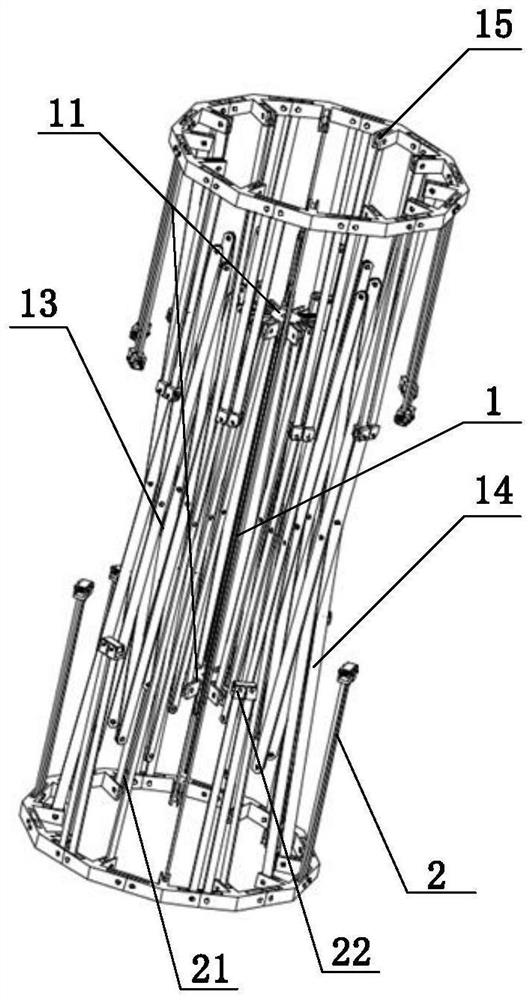

[0034] In this embodiment, the torsion spring-driven scissor hinge ring rib-type deployable antenna mechanism includes N radially deployable units 1 and N circumferentially deployable units 2, where N is an integer greater than or equal to 3, and the radially deployable unit The exhibition units 1 are connected to each other by sharing two inner faceplates 11 and N circumferentially deployable units 2, and the multiple circumferentially deployable units 2 are connected end to end through the shared two outer faceplates 15 to form a circumferential annular truss assembly. , the circumferential annular truss components are all multi-faceted annular truss structures after being unfolded and folded.

[0035] The operation process of this embodiment is implemented as follows:

[0036] The torsion spring-driven scissor-hinged ring-rib-type deployable antenna mechanism of the present invention can adjust the size and quantity of the radially deployable unit 1 and the circumferentiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com