Explosion-proof fuel gas pipeline

A gas and pipeline technology, applied in the direction of pipeline protection, pipe/pipe joint/pipe fitting, pipeline damage/wear prevention, etc., can solve the problems of gas pipeline explosion, building collapse, damage to people's lives and property, etc., achieve fast heat conduction, prevent backflow fire effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

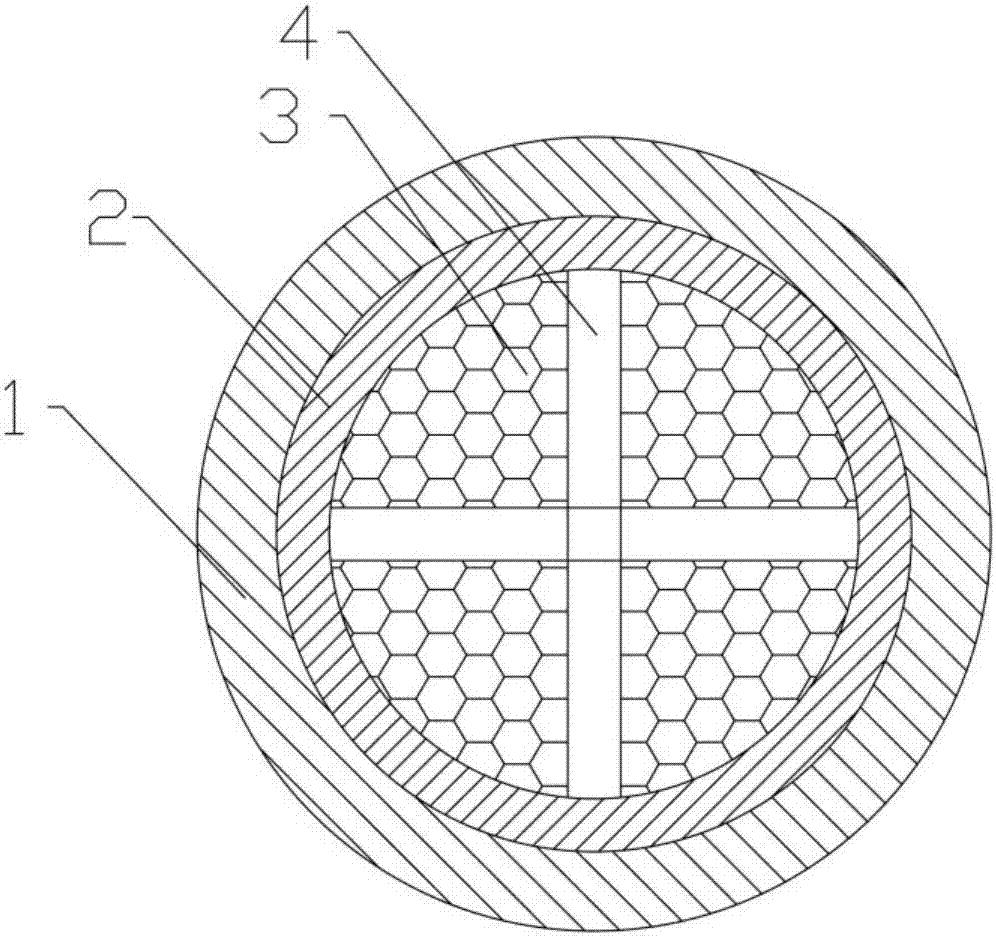

[0016] refer to figure 1 , an explosion-proof gas pipeline, including a gas delivery pipe 2, the cavity of the gas delivery pipe 2 is filled with a plurality of ventilated explosion-proof balls 3, and the plurality of explosion-proof balls 3 are fixed on the gas delivery pipe 2 by brackets 4 Inside, specifically, there are brackets 4 at both ends of each gas delivery pipe 2, and the brackets 4 only prevent the explosion-proof ball 3 from moving in the tube. The brackets 4 at both ends of the gas delivery pipe 2 are fixed to the gas delivery pipe 2 by welding, and the brackets located in the gas delivery pipe 2 only need to be plugged in to prevent the explosion-proof ball 3 from rolling. Of course, the gas delivery pipe 2 The inner cavity is preferably filled with the explosion-proof ball 3, so that the explosion-proof effect is better.

[0017] R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com