Intelligent pipeline and connecting method thereof

A technology of intelligent pipeline and connection method, which is applied in the direction of flange connection, pipeline protection, water supply main pipeline, etc., can solve the problems that the pipeline is easy to be frozen and cracked, the weight of the pipeline is increased, and the pipeline is easy to be damaged, so as to avoid heat loss and structure The effect of stabilizing and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

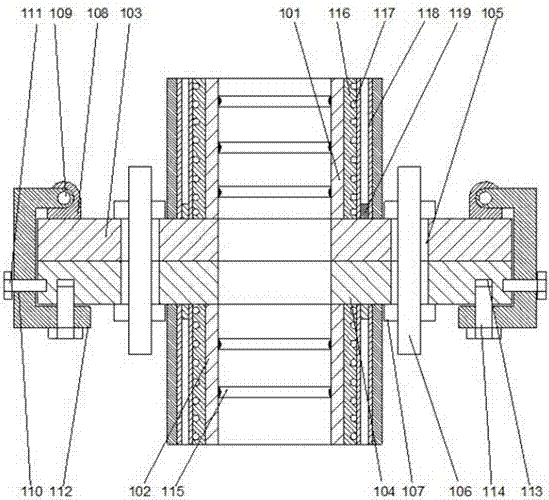

[0020] Such as figure 1 As shown, a kind of anti-freezing and cracking intelligent pipeline connection equipment for large-scale smart city industrial buildings includes a first connecting sleeve 101 and a second connecting sleeve 102, and the first connecting sleeve 101 and the second connecting sleeve The sleeves 102 are all hollow cylindrical structures, and a protective cover 116 is set on the outside of the first connecting sleeve 101 and the second connecting sleeve 102. The inner wall of the protective cover 116 is provided with a spiral A heating tank arranged in a shape, a heating wire 117 is arranged in the heating tank, the protective cover 116 has an inner and outer two-layer structure, and the heating tank is located on the inner wall of the inner layer structure of the protective cover 116 , a cavity is provided between the inner and outer two-layer structure, heat-insulating sponges 118 are respectively bonded on the opposite end faces of the inner and outer two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com