Orthogonal laminated wood shear wall with replaceable wall feet

A shear wall and glulam technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems of difficult repair and high repair costs, and achieve the effects of reducing repair costs, high cost performance, and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

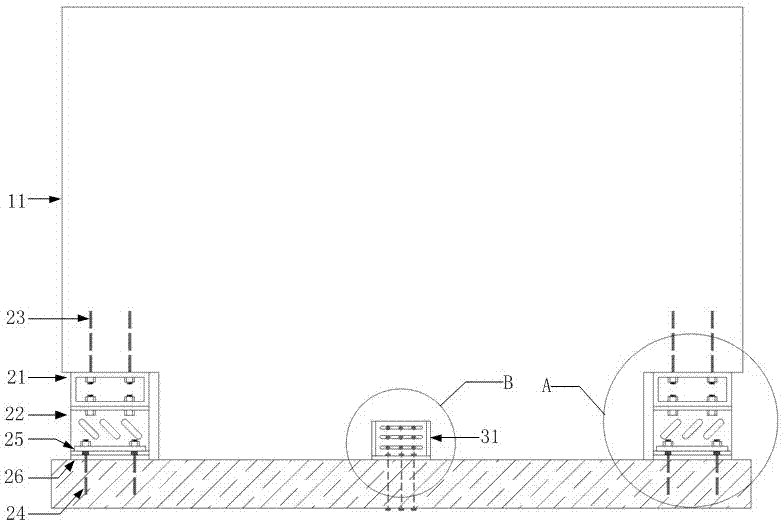

[0030] Embodiment 1: as figure 1 As shown, the cross-glued wood shear wall with replaceable energy-dissipating components of the present invention includes a cross-glued wood shear wall 11, a replaceable foot member and its connector, and a middle connector 31 of the shear wall; For the cross-glued timber shear wall 11, a part of the foot of the wall is excavated for each piece of wall to install replaceable foot components and their connectors.

Embodiment 2

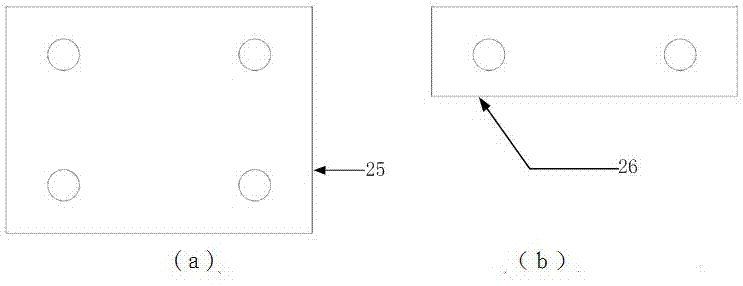

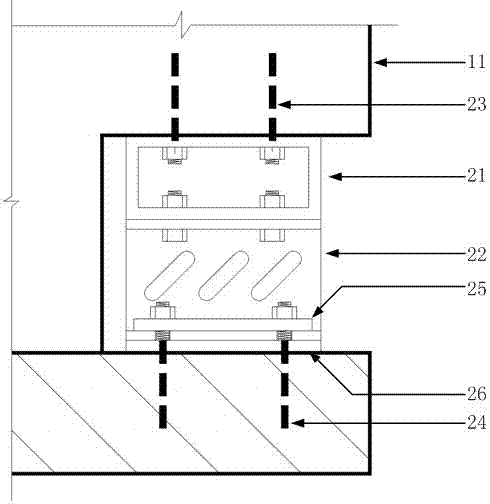

[0031] Embodiment 2: as Figure 2 to Figure 6As shown, the first planting bar 23 and the second planting bar 24 are made of high-strength screw or high-grade rebar to ensure sufficient tensile and shear strength. The first planting bar 23 is pre-embedded in the orthogonal In the glulam shear wall, the extension length of the end is enough to install the box-shaped pad 21; Backing plate 26 and I-shaped energy dissipation member 22 . The box-shaped mattress 21 is made of ordinary carbon structural steel by welding, and the soft steel I-shaped energy-dissipating member 22 is made of low-yield point steel by welding. The first steel backing plate 25 and the second steel backing plate 26 are made of ordinary carbon structural steel, and the bolts are high-strength bolts. First install the box-shaped pad 21, and tighten the nuts of the first planting bar 23, then put the second steel backing plate 26 into the installation position, then put the I-shaped energy-dissipating member 2...

Embodiment 3

[0032] Embodiment 3: as Figure 7 As shown, the ribbed angle steel 31 can be made of ordinary angle steel, and the stiffeners are welded on the angle steel by welding; the side where the ribbed angle steel 31 is connected with the cross-glued wood shear wall 11 has a plurality of standard round holes, through Use nails or self-tapping screws to securely connect the ribbed angle steel 31 to the cross-laminated wood shear wall 11; the other side of the ribbed angle steel 31 has multiple oblong holes, through which the high-strength bolts are used to connect with the floor, and apply The pretightening force, the number of high-strength bolts and the pretightening force must be designed so that the horizontal friction force provided has an appropriate value. When the structure is subjected to little horizontal action, the friction force provided by the pretightening force is sufficient to resist the horizontal force. The bolts There is no sliding between the bolt and the ribbed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com