Semi-rigid node friction energy dissipation device

A friction energy dissipator, semi-rigid technology, applied in the direction of building maintenance, building components, building structure, etc., can solve the problems of difficult to control friction preload, difficult to control friction coefficient, large working space, etc., to achieve uniform friction Stable, flexible and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation on the invention.

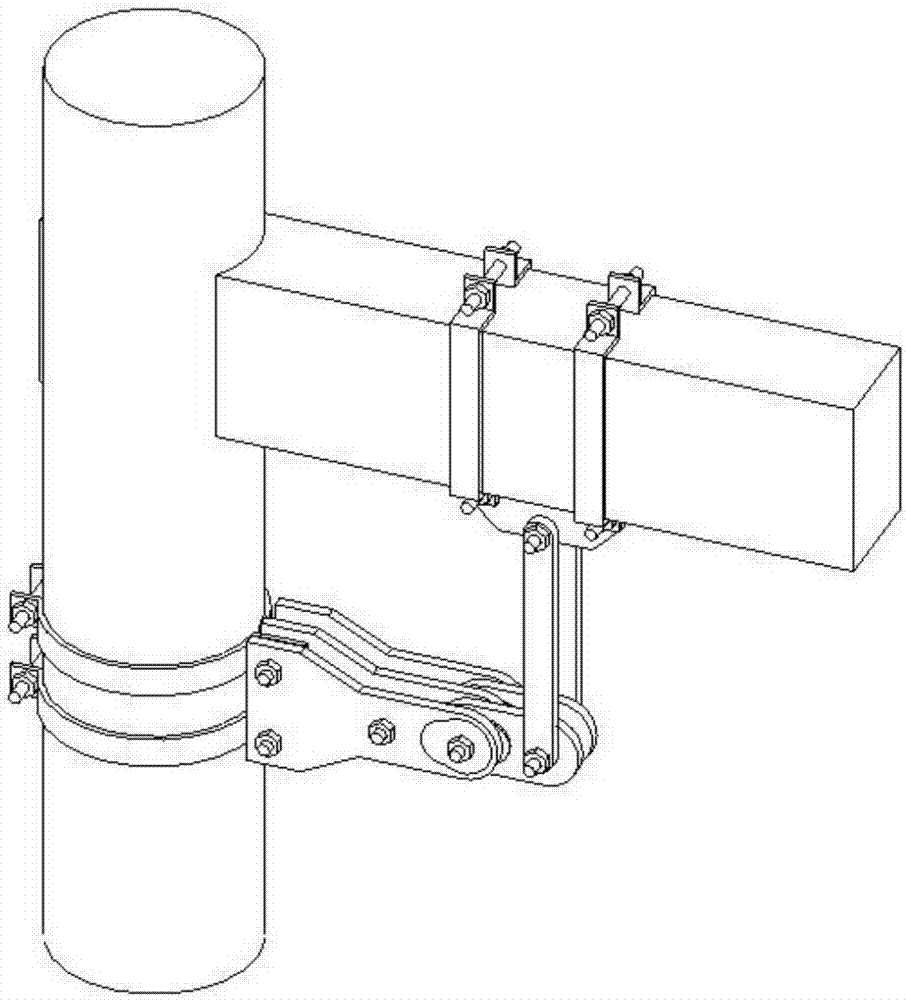

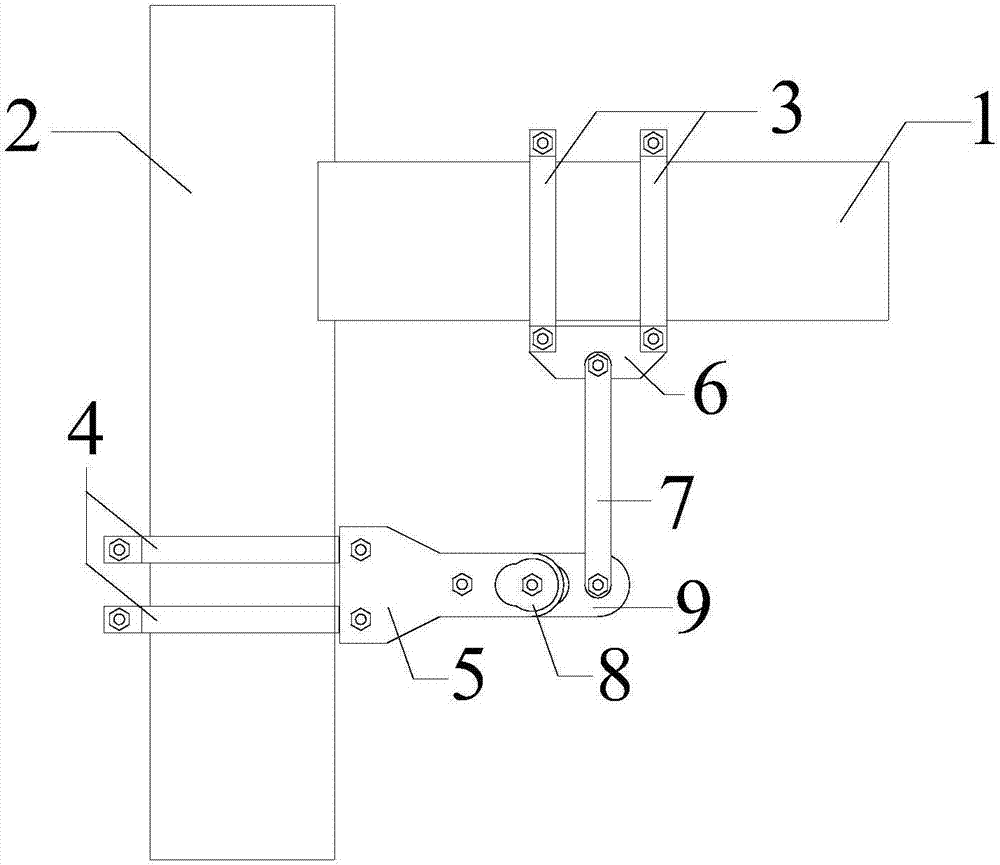

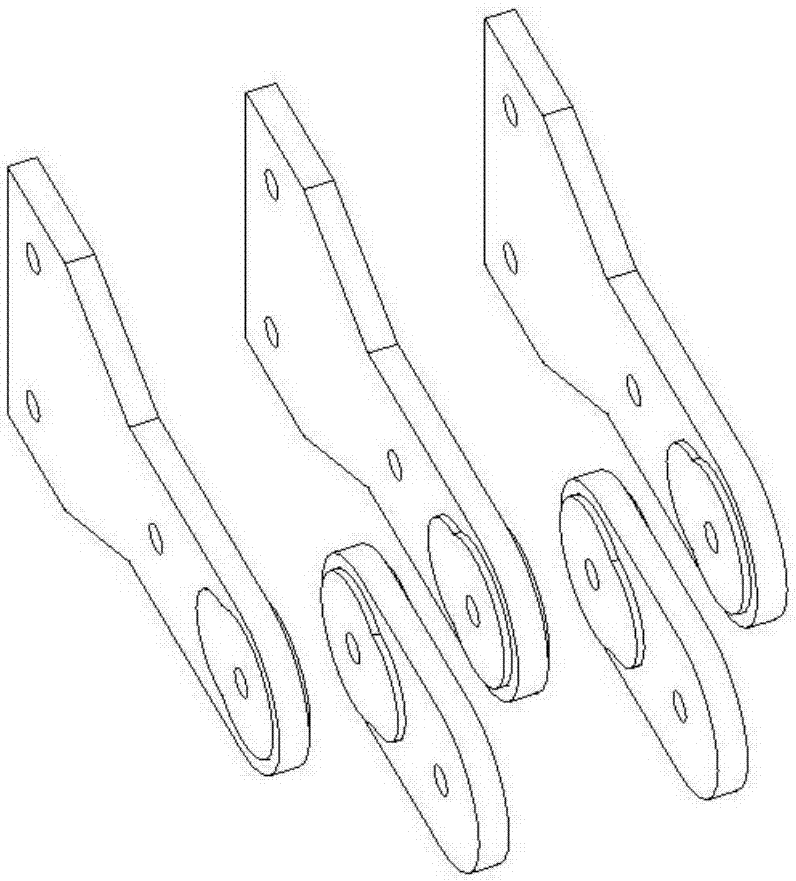

[0034] like figure 1 , figure 2 As shown, a semi-rigid node friction energy dissipator includes a wooden column 2 and a wooden beam 1 connected to the wooden column 2 through a mortise and tenon joint, and there is a friction loss between the wooden column 2 and the wooden beam 1 Energy dissipators, wherein the frictional energy dissipators are respectively connected to the wooden beam 1 through the beam end connector 3, and connected to the wooden column 2 through the column end connector 4, and the frictional energy dissipator includes the The beam-end connecting rod 7 and n column-end connecting rods 5 connected to the column-end connector 4, and the n column-end connecting rods 5 are connected to the beam-end connecting rod 7 through intermediate connectors 9 with friction plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com