Sludge treatment method

A treatment method and sludge technology, applied in water/sludge/sewage treatment, water/sewage treatment, special treatment targets, etc., can solve the problem of inconsistent conclusions about the dosage ratio of chemicals, difficult sedimentation of sludge suspended matter, and improved Sludge treatment costs and other issues, to achieve the effect of facilitating large-scale industrial production, less equipment, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for treating sludge, comprising the steps of:

[0032] (1) Get seven groups of raw sludge (the content of heavy metals in the raw sludge is shown in Table 1), and use concentration of 5mol / L H 2 SO 4 The solution adjusted the pH value of each group of sludge to 2.

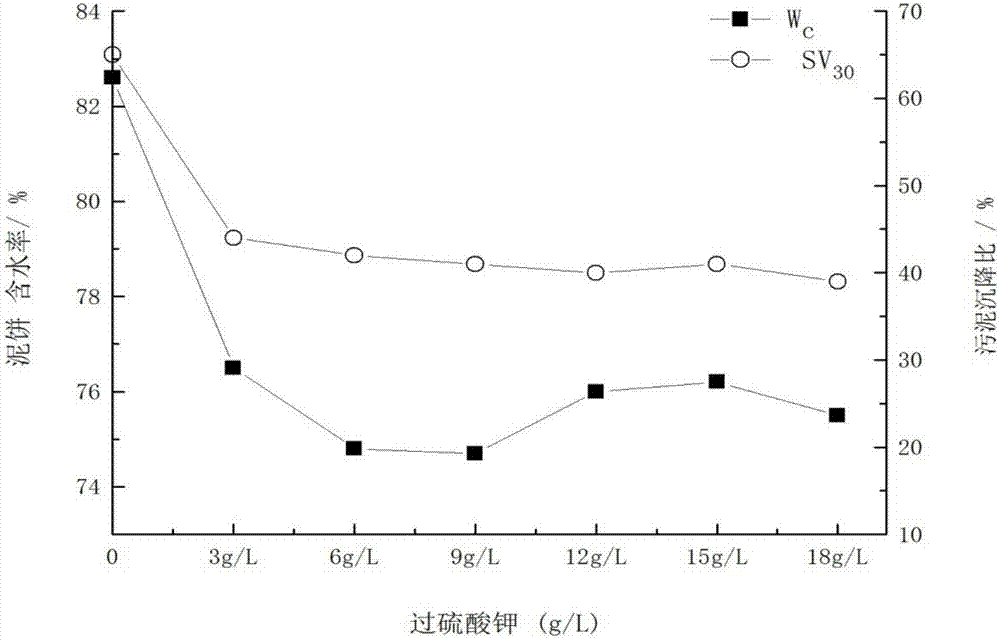

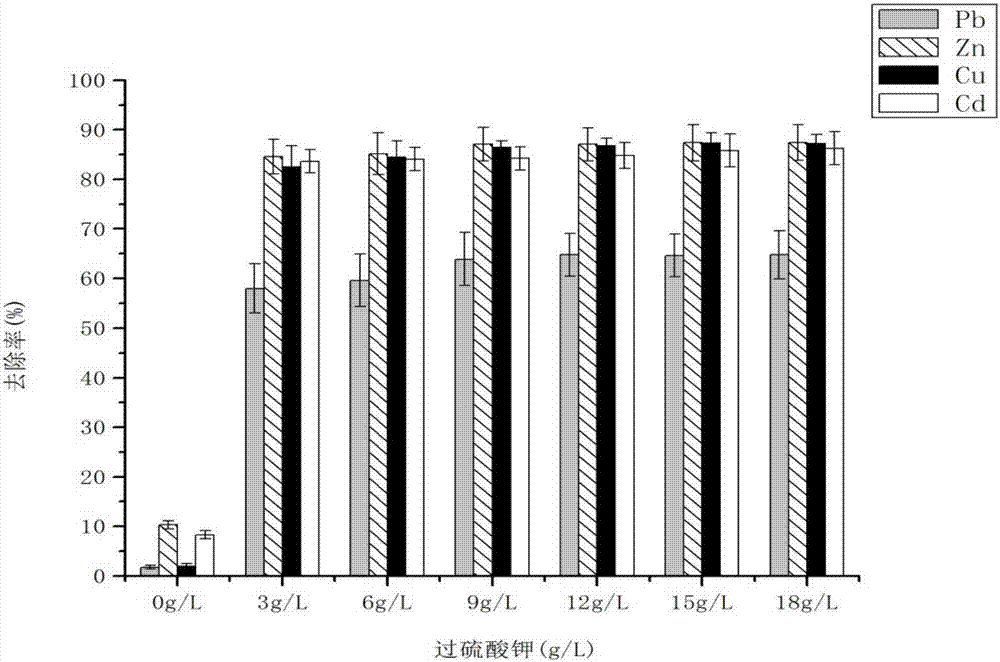

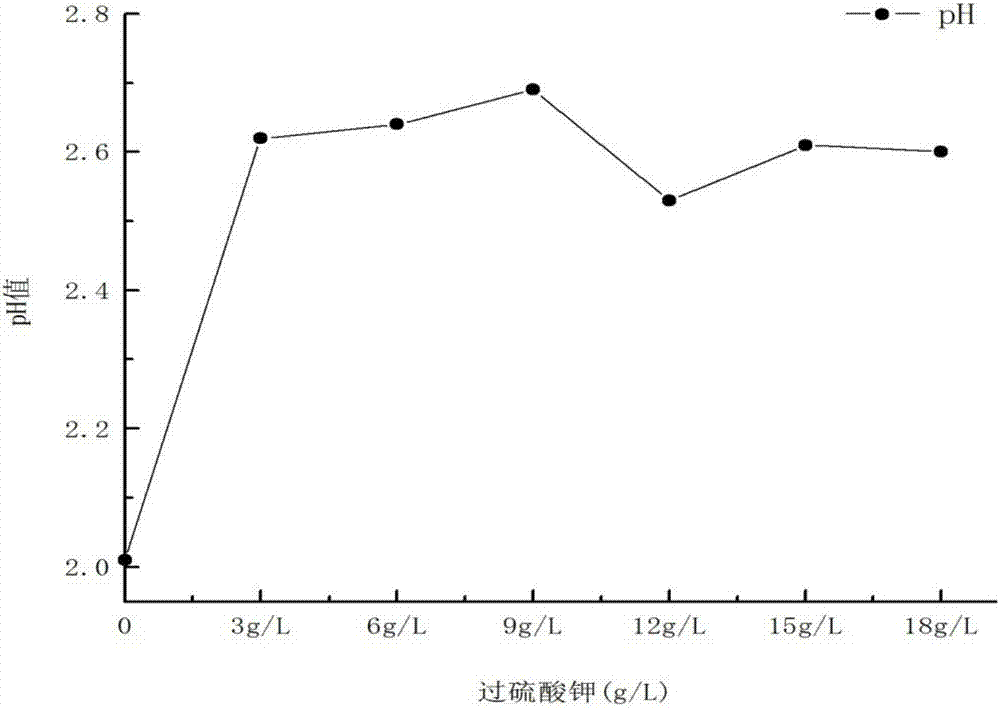

[0033] (2) According to the addition amount, it is 0, 3g / L, 6g / L, 9g / L, 12g / L, 15g / L, 18g / L respectively (that is, adding potassium persulfate 0, 3g, 6g, 9g, 12g, 15g, 18g), add potassium persulfate to the sludge after pH adjustment in step (1), stir under a constant temperature magnetic stirrer, oxidize at 25°C for 60min, and centrifuge the product obtained from the oxidation treatment Separation and suction filtration to obtain the sludge cake and supernatant I, and complete the treatment of the sludge.

[0034] Table 1 Contents of heavy metals in raw sludge

[0035] heavy metal

Pb (mg / kg)

Zn(mg / kg)

Cu(mg / kg)

Cd (μg / kg)

content

204.5

521.53

278.56

121...

Embodiment 2

[0045] A method for treating sludge, comprising the steps of:

[0046] (1) Take five groups of sludge (the content of heavy metals in the sludge is shown in Table 1), and use the concentration of 5mol / L H 2 SO 4 The solution adjusted the pH value of each group of sludge to 1, 2, 3, 4, 5.

[0047] (2) be 9g / L by addition (that is, add potassium persulfate 9g in every liter of sludge), add potassium persulfate respectively in the sludge after step (1) adjusts pH, stir under constant temperature magnetic stirrer, Oxidation treatment at 25°C for 60 minutes, centrifugation and suction filtration of the product obtained from the oxidation treatment to obtain sludge cake and supernatant I, and complete the treatment of the sludge.

[0048] Get the sludge mud cake that obtains among the embodiment 2, put into oven and dry 8.0h, then take by weighing 0.5g dry sludge and digest, measure the heavy metal content in the sludge, the result is as follows Figure 4 shown. Figure 4 It is ...

Embodiment 3

[0050] A method for treating sludge, comprising the steps of:

[0051] (1) Take four groups of sludge (the content of heavy metals in the sludge is shown in Table 1), and use the concentration of 5mol / L H 2 SO 4 The solution adjusted the pH value of each group of sludge to 2.

[0052] (2) According to the addition amount is respectively 9g / L (that is, add potassium persulfate 9g in every liter of sludge), add potassium persulfate respectively to the sludge after pH adjustment in step (1), stir under constant temperature magnetic stirrer , oxidized at 25°C for 60 minutes, centrifuged the product obtained from the oxidized treatment, and filtered it with suction to obtain sludge cake and supernatant I.

[0053] (3) 0.25%, 0.5%, 0.75%, 1.0% by mass ratio (that is, the mass ratio of calcium oxide to supernatant I is 0.25%, 0.5%, 0.75%, 1.0%), to step (2) Calcium oxide was added to the obtained supernatant Ⅰ, and the reaction was carried out under stirring conditions, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com