Safe goods lifting mechanism

A lifting mechanism and safety technology, applied in the field of lifts, can solve problems such as non-compliance, unstable guide rail frame joints, etc., to achieve the effects of ensuring balance monitoring, maintaining stability in the conveying process, and reducing additional consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

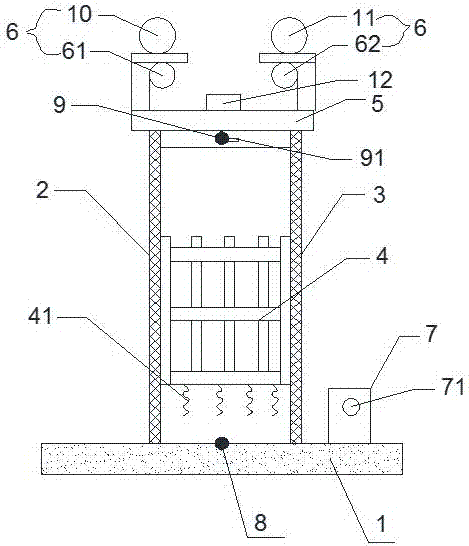

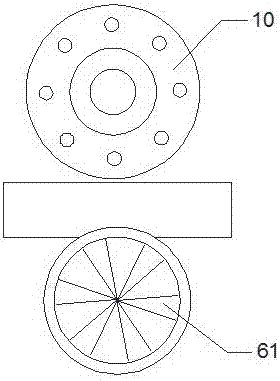

[0030] Such as figure 1 As shown, the safety cargo lifting mechanism of this embodiment includes a base frame 1, a first rail frame 2 and a second rail frame 3 that are parallel to each other, and the first rail frame 2 and the second rail frame are arranged on the base frame 1. The frames 3 are vertically fixed on the base frame 1. A transport box 4 is arranged between the first rail frame 2 and the second rail frame 3. The transport box 4 may be a box composed of a wooden frame, which is fastened by screws to facilitate ventilation during cargo transportation. Several spring buffers 41 are provided at the bottom of the transport box 4. The spring buffer is an energy-storing buffer. When the box is dropped in an emergency, the spring buffer is impacted, and the kinetic energy and potential energy of the box can be converted into spring elastic potential energy to ensure that the box lands on the ground as quickly as possible and avoid repeated rebounds. The damage caused.

[0...

Embodiment 2

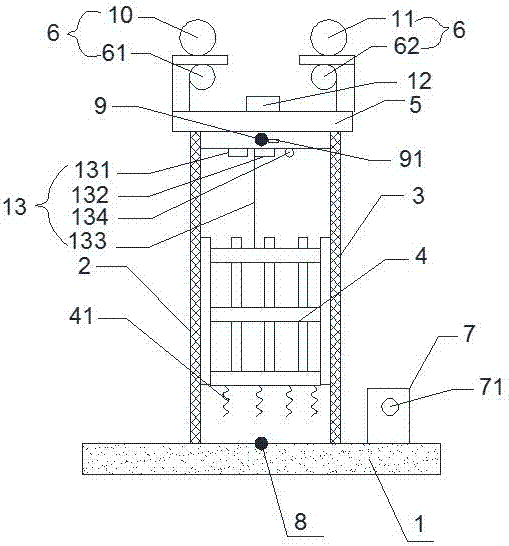

[0036] Such as figure 2 As shown, in addition to the structure of embodiment 1, the safety cargo lifting mechanism of this embodiment also includes an emergency braking device 13, which includes a speed reducer 131 and a speed limiter 132 arranged at the bottom of the top frame. And the safety wire rope 133 connected to the upper end of the transport box 4, the speed reducer 131 and the speed limiter 132 are connected to the electric control device 7, and an alarm light 134 is also included, which is electrically connected to the speed reducer 131 and the speed limiter 132.

[0037] The speed reducer 131 can automatically reduce the acceleration when the transport box rises to the top end or drops to the bottom end, which is helpful for smooth operation; the speed limiter 132 monitors the moving speed of the box in real time. When an overspeed situation occurs, that is At 115% of the rated speed of the elevator, it can send out a signal in time, and then produce mechanical action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com