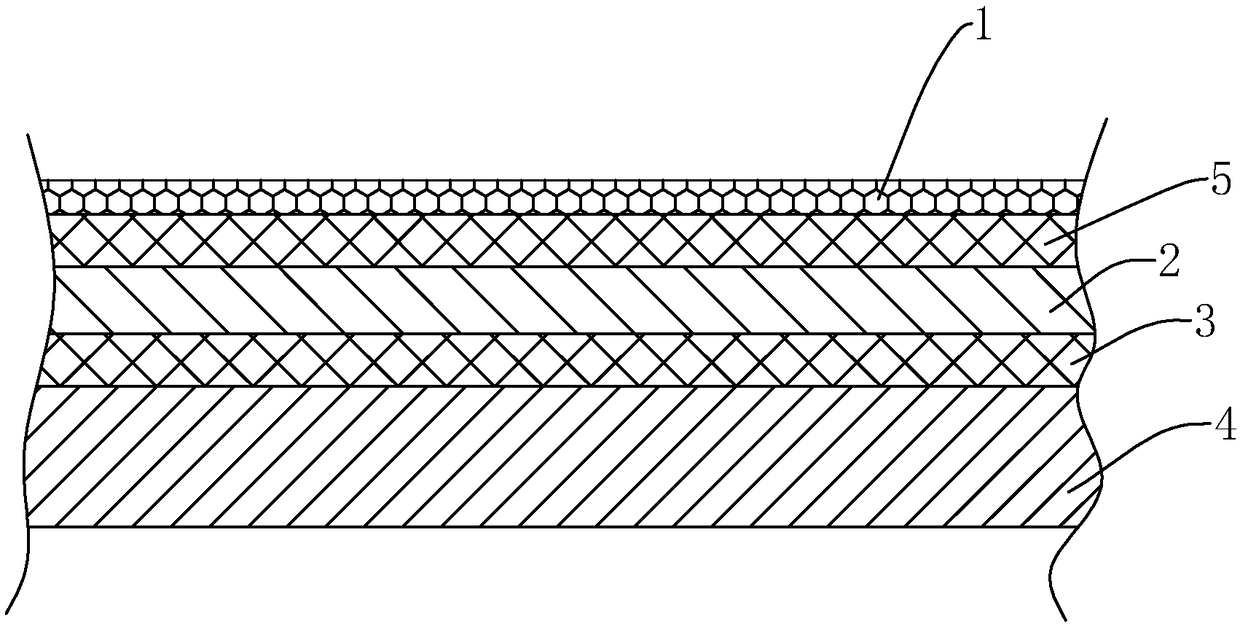

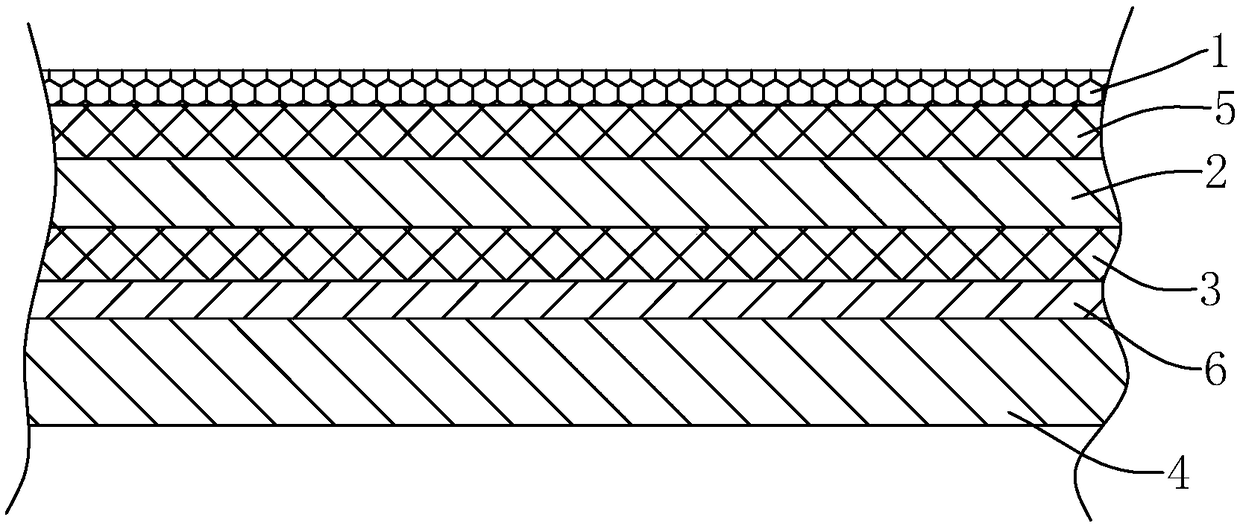

High gloss anti-glare film

A high-brightness and anti-settling agent technology, applied in the field of composite films, can solve problems such as poor reflection effect, rising temperature, and affecting indoor personnel, and achieve the effects of reducing ultraviolet rays, reducing air content, and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: a kind of matte oil, by weight, comprises following raw material: the solvent of 50 parts by weight, the polyamide resin of 20 parts by weight, the matte powder of 15 parts by weight, the nano base of 12 parts by weight, 12 parts by weight Parts by weight of barium sulfate, 8 parts by weight of nano metal powder, 5 parts by weight of curing agent, 1.5 parts by weight of matting agent, 1 part by weight of anti-settling agent, 0.5 parts by weight of dispersant, 0.1 parts by weight of defoamer , 0.1 parts by weight of color paste.

Embodiment 2

[0035] Embodiment 2: a kind of matte oil, by weight, comprises following raw material: the solvent of 52 parts by weight, the polyamide resin of 22 parts by weight, the matte powder of 17 parts by weight, the nano base of 13 parts by weight, 13 parts by weight The barium sulfate of parts by weight, the nano-metal powder of 9 parts by weight, the curing agent of 5.5 parts by weight, the matting agent of 1.7 parts by weight, the anti-settling agent of 1.2 parts by weight, the dispersant of 0.8 parts by weight, the defoamer of 0.12 parts by weight , 0.12 parts by weight of the color paste.

Embodiment 3

[0036] Embodiment 3: a kind of matte oil, by weight, comprises following raw material: the solvent of 54 parts by weight, the polyamide resin of 24 parts by weight, the matte powder of 19 parts by weight, the nano alkali of 14 parts by weight, 14 parts by weight Parts by weight of barium sulfate, 10 parts by weight of nano metal powder, 6 parts by weight of curing agent, 1.9 parts by weight of matting agent, 1.4 parts by weight of anti-settling agent, 1 part by weight of dispersant, 0.14 parts by weight of defoamer , 0.14 parts by weight of the color paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com