Extruding and pulling device for cable loose tubes

A technology of traction device and loose tube, which is applied in the direction of tubular objects, other household appliances, household appliances, etc. It can solve the problems of affecting the transmission performance of optical fibers, the inability to apply loose tubes, and the uncontrollable excess length of PP material loose tubes. It achieves the effect of wide application range, simple structure and good drawing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

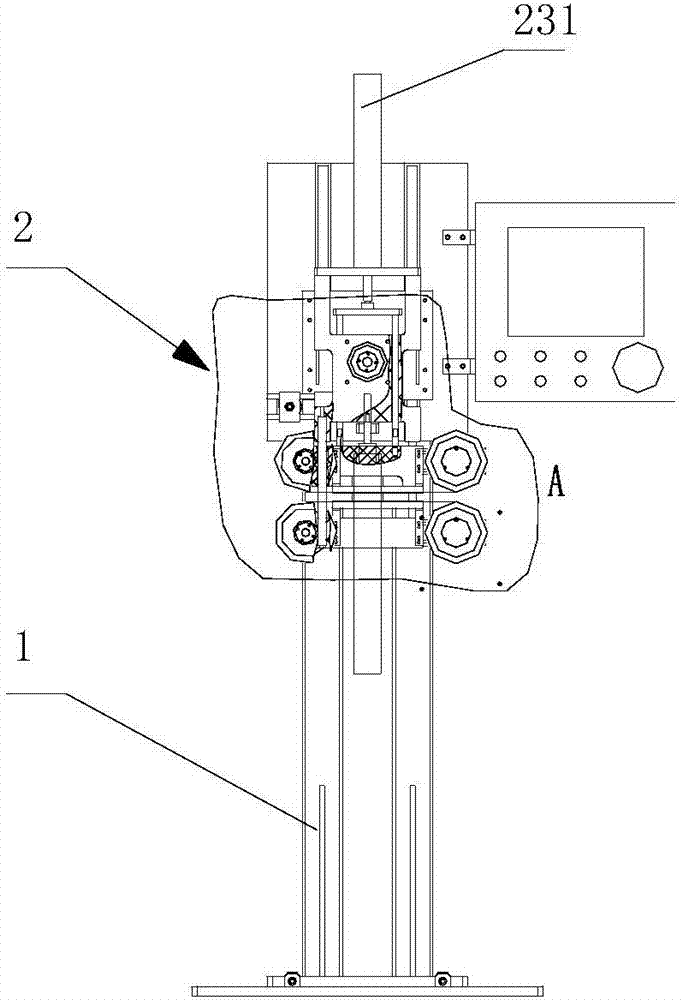

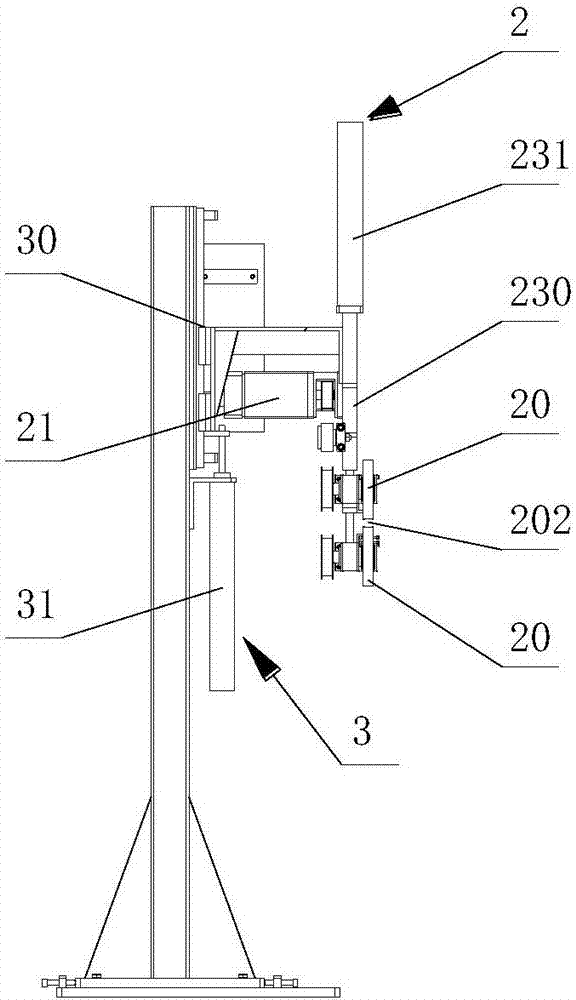

[0029] see Figure 1 to Figure 3 As shown, the embodiment of the present invention provides an extrusion and pulling device for a loose tube of an optical cable, which includes a frame body 1 and an extrusion mechanism 2 arranged on the frame body 1 .

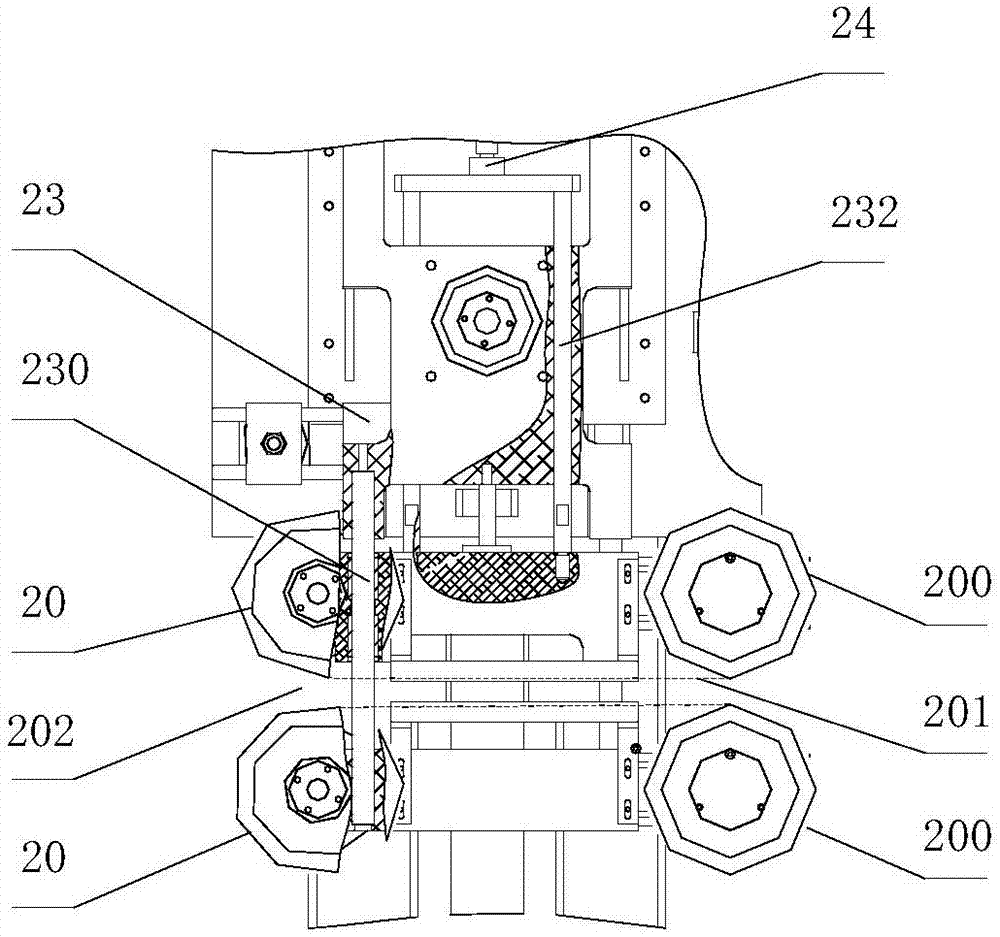

[0030] The extruding mechanism 2 includes: two sets of clamping wheels 20 and a driving mechanism 21 arranged in parallel. The clamping wheel set 20 is arranged on the frame body 1, and the clamping wheel set 20 includes at least two rollers 200 and a traction belt 201 matched with the two rollers 200, and a belt for extruding traction is formed between the two traction belts 201. The channel 202 of the loose tube of the optical cable, the driving mechanism 21 is connected with the roller 200 and drives the roller 200 to rotate.

[0031] The extrusion mechanism 2 also includes a pressure mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com