Glass mold machining cutter placement device

A technology for processing knives and glass molds, which is applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems affecting the processing accuracy of glass molds, and achieve the effects of simple structure, preventing dimensional errors, and convenient placement and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

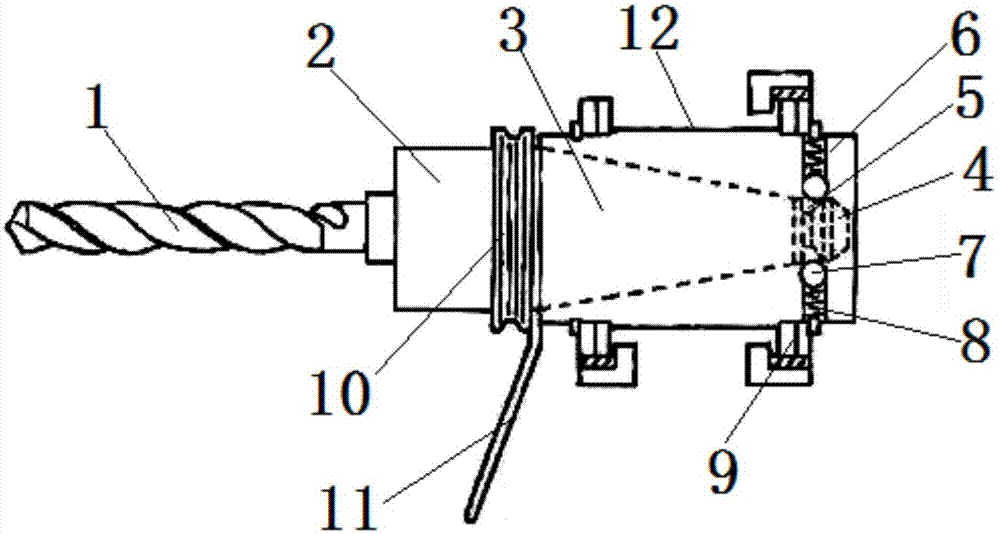

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] like figure 1 As shown, a glass mold processing cutter placement device includes a cutter, and the cutter is composed of a cutter head 1, a cutter seat 2 and a connecting piece 3, and the cutter head 1 is installed on one side of the cutter seat 2, and the connection The piece 3 is installed on the other side of the knife seat 2, the connecting piece 3 is tapered, the tail end of the connecting piece 3 is connected with a round head 4, and the round head 4 and the tail end of the connecting piece 3 have a connecting groove 5.

[0014] The connecting piece 3 is covered with a placement cylinder 12, and in order to facilitate fixing the placement cylinder 12, a fixing fast 9 is installed on the placement cylinder 12. On the other side of the opening of the placement cylinder 12, two installation pipes 6 are arranged in the plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com