Municipal waste disposal device

A treatment device and municipal waste technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of air pollution, landfill site consumption of land resources, difficult to handle urban waste, etc., to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

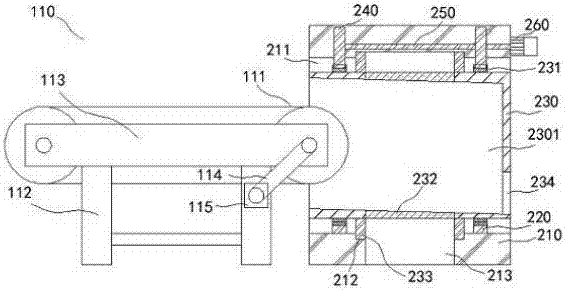

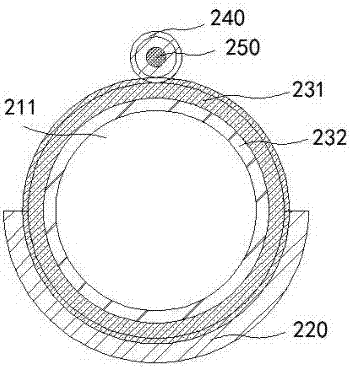

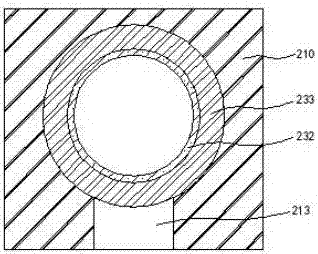

[0031] Such as Figure 1~3 Shown is a kind of municipal waste disposal device of this embodiment, comprising a conveyor 110 and a screening device 210, the conveyor 110 includes a conveyor belt 111, and the screening device 210 is provided with a cavity 211 with openings at both ends, and the bottom of the cavity wall of the cavity 211 There are not less than two semicircular toothed belts 220, and a coaxial drum 230 is arranged inside the toothed belt 220, and a ring gear 231 is arranged on the circumference of the drum 230, and the ring gear 231 meshes with the toothed belt 220, and the inside of the drum 230 A working chamber 2301 is provided and one end of the conveyor belt 111 extends into the working chamber 2301;

[0032] Rotating drum 230 cylinder wall is provided with filter screen 232 and retaining ring 233 on the circumferential direction, and filter screen 232 communicates with working chamber 2301, and retaining ring 233 has two and filter screen 232 is positioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com