Method for modifying ultrafiltration membrances through metal cation cross-linked graphene oxide nanosheets

A technology of graphene nanosheets and metal cations, applied in chemical instruments and methods, ultrafiltration, membrane technology, etc., can solve problems such as the complexity of the modification process of ultrafiltration membranes, improve water treatment efficiency, facilitate promotion, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

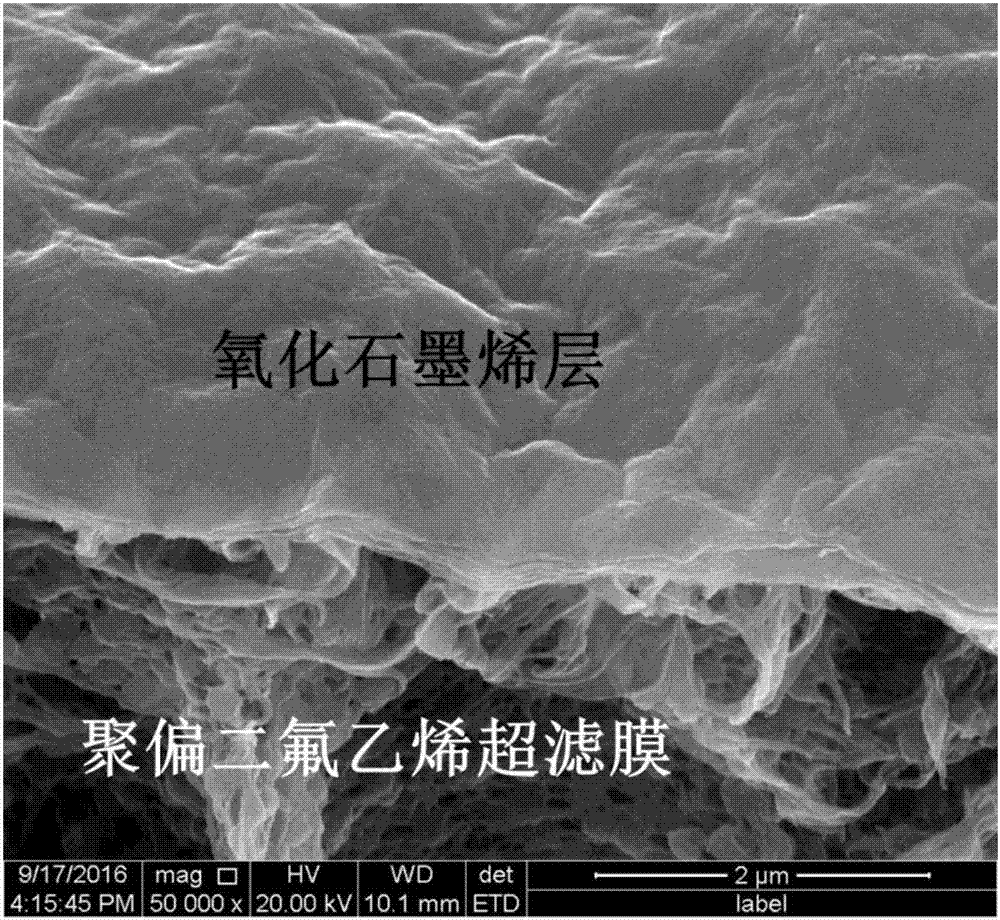

[0025] 1) Add 0.1 mg of 1-layer graphene oxide nanosheets to 100 ml of deionized water, then add 2.415 mg of aluminum chloride hexahydrate to another 100 ml of deionized water, and mix the two solutions evenly. After that, place the membrane in the ultrafiltration cup, pour the mixed solution into the ultrafiltration cup, and filter for 2-5 minutes at a constant pressure of 0.05MPa to successfully load graphene oxide nanosheets on polyvinylidene fluoride The surface of the ultrafiltration membrane, the loaded membrane such as figure 1 shown.

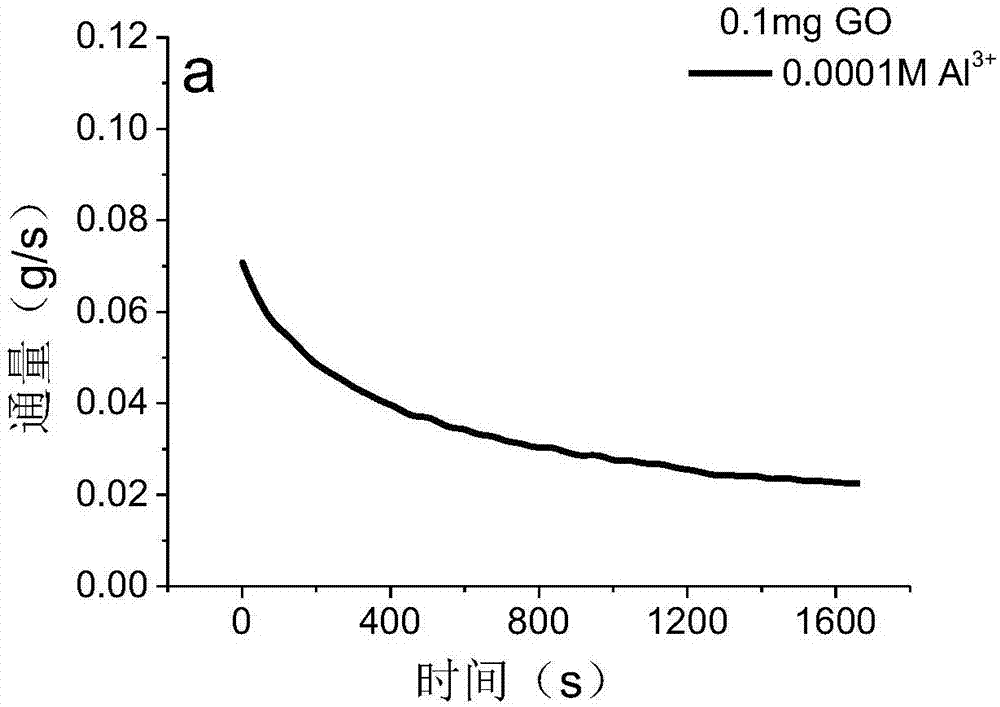

[0026] 2), 1 milliliter of 1g / L bovine serum albumin (BSA) stock solution was added to 100 milliliters of deionized water, and the BSA solution was pre-deposited with 0.1 mg of graphene oxide nanosheets in the above step 1). For ultrafiltration of vinyl fluoride ultrafiltration membrane, use an electronic balance to connect to a data display to collect data and explore the change of membrane flux. Such as figure 2 As shown, the decay...

Embodiment 2

[0028] 1) Add 1 mg of 60-layer graphene oxide nanosheets to 100 ml of ethanol, then add 27.05 mg of ferric chloride hexahydrate to another 100 ml of deionized water, and mix the two solutions evenly. After that, place the membrane in the ultrafiltration cup, pour the mixed solution into the ultrafiltration cup, and filter for 2-5 minutes at a constant pressure of 0.2MPa to successfully load graphene oxide nanosheets on polyvinylidene fluoride Ultrafiltration membrane surface.

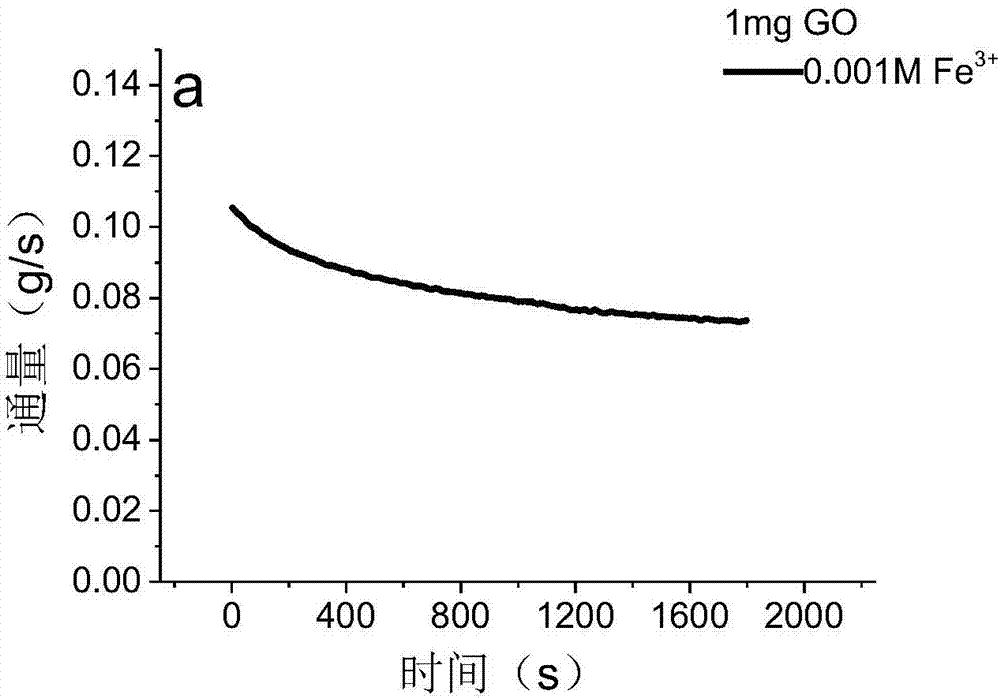

[0029] 2), 1 milliliter of 3g / L sodium humate (HS) stock solution was added to 300 milliliters of deionized water, and the HS solution was pre-deposited with the polyylidene fluoride of 1 mg graphene oxide nanosheet in the above step 1). For ethylene ultrafiltration membrane ultrafiltration, use an electronic balance to connect to a data display to collect data and explore changes in membrane flux. Such as image 3 shown. The membrane flux stability is greatly improved, after such as Figure 1 After...

Embodiment 3

[0031] 1), 15 milligrams of 100 layers of graphene oxide nanosheets were added to 100 milliliters of deionized water, then 1666.1 mg of aluminum sulfate octadecahydrate and 974.8 mg of hydrated ferric sulfate were added to another 100 milliliters of deionized water, and the two The solutions are mixed evenly. After that, place the membrane in the ultrafiltration cup, pour the mixed solution into the ultrafiltration cup, and filter for 2-5 minutes at a constant pressure of 0.4MPa to successfully load graphene oxide nanosheets on polyvinylidene fluoride Ultrafiltration membrane surface.

[0032] 2), 1 ml of 1g / L sodium alginate (SA) stock solution was added to 100 ml of deionized water, and the SA solution was pre-deposited with 15 mg of graphene oxide nanosheet polyylidene fluoride in the above step 1). For ethylene ultrafiltration membrane ultrafiltration, use an electronic balance to connect to a data display to collect data and explore changes in membrane flux. Such as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com