Three-column amorphous iron core with pulling plate and manufacturing method thereof

A technology of amorphous iron core and manufacturing method, which is applied in the manufacture of inductors/transformers/magnets, parts of transformers/inductors, electrical components, etc., which can solve the problems of weak anti-sudden short-circuit ability, reduced transformer operation stability, and insulation resistance. No high problems, to achieve the effect of reducing material costs, ensuring stability, and saving usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

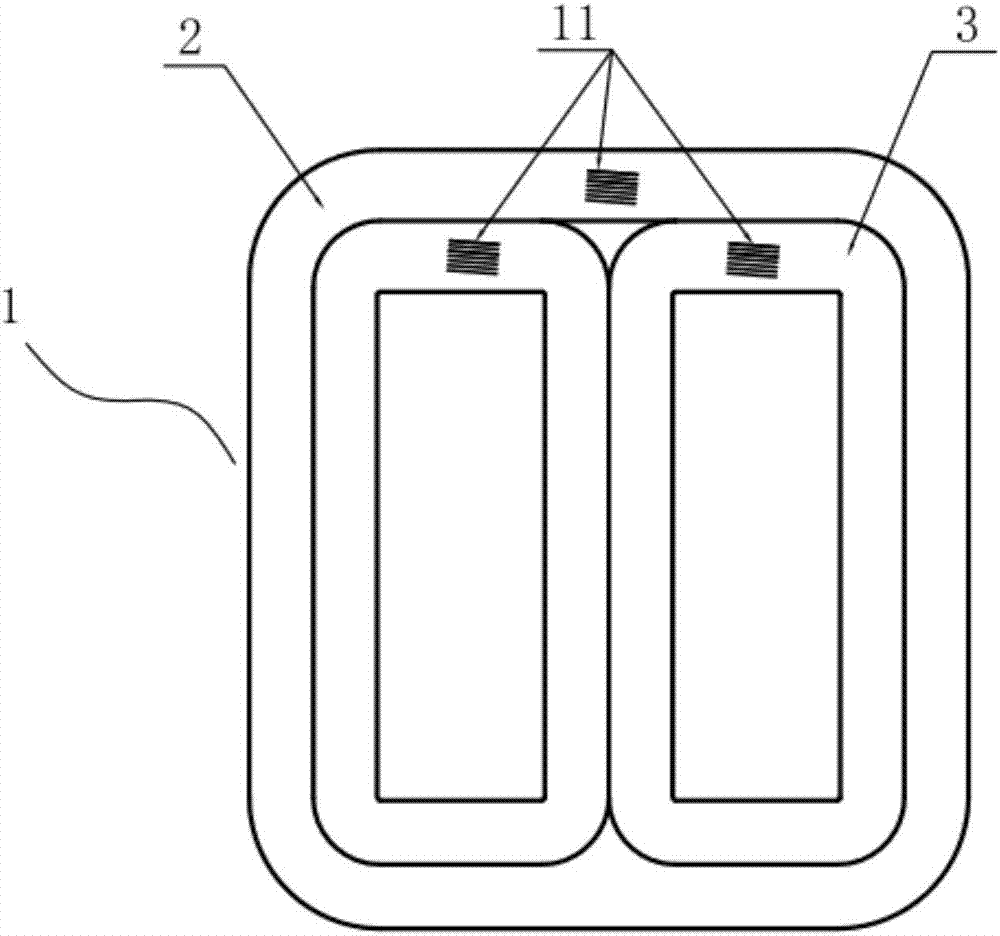

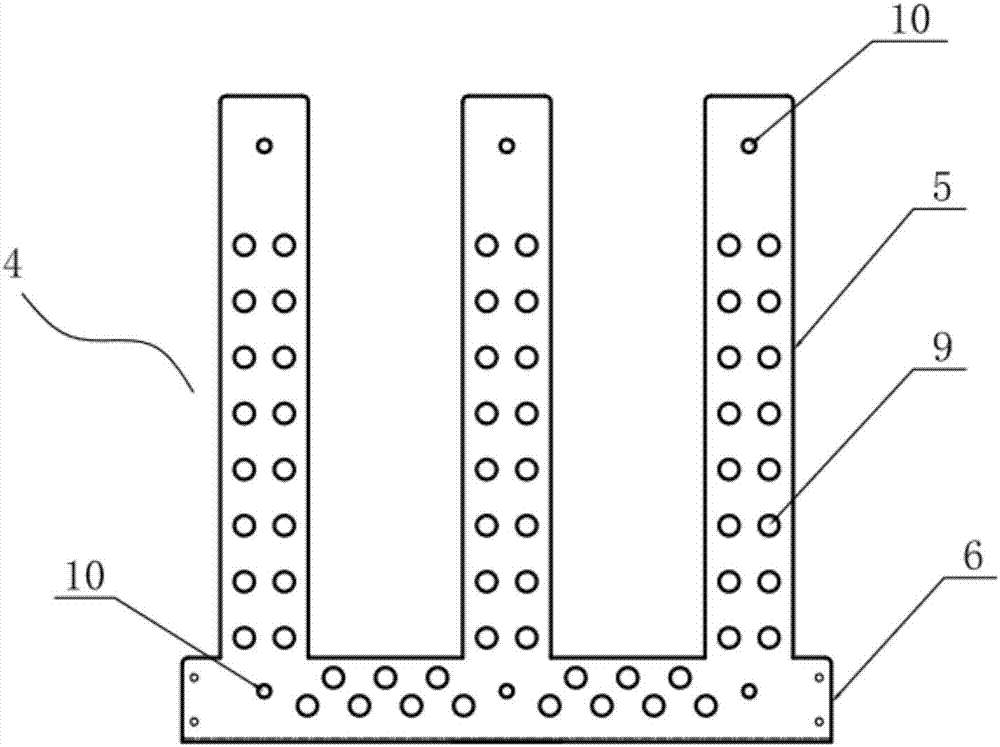

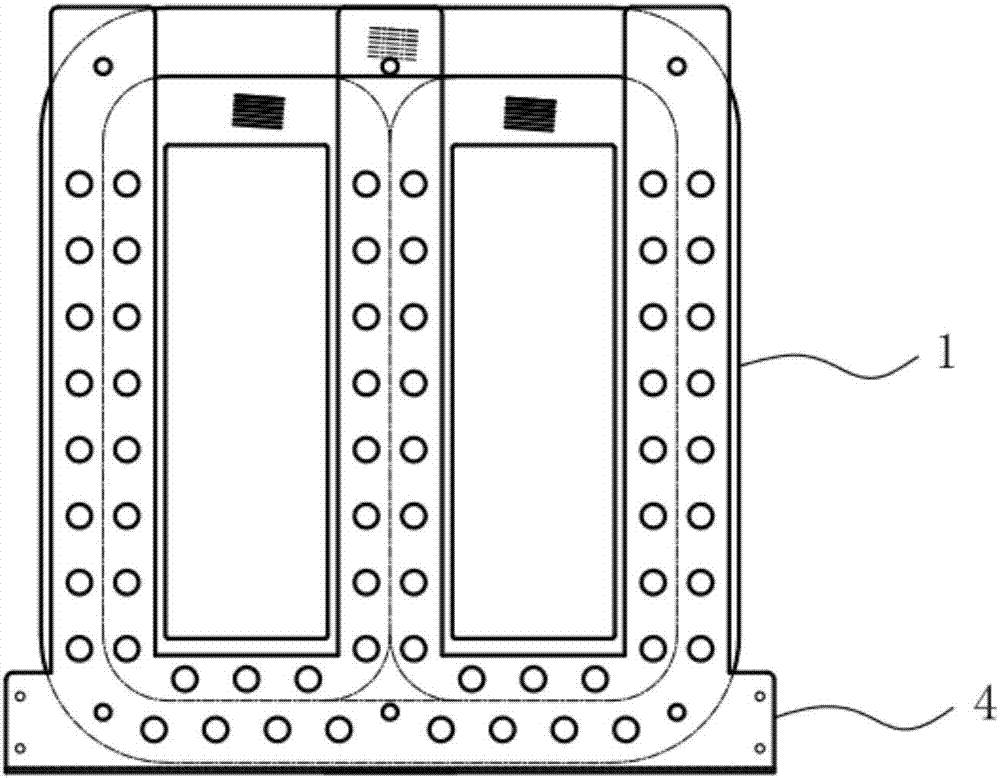

[0030] like Figure 1 to Figure 5 As shown, a three-column amorphous iron core with tie plates includes an amorphous core body 1 , tie plates 2 , grid layout plates 7 and composite templates 8 . Wherein, the amorphous iron core body 1 includes an outer frame iron core 2 and two inner frame iron cores 3, and the two inner frame iron cores 3 are arranged side by side in the outer frame iron core 1, and the outer frame iron core 2 and the inner frame iron core 3 are One-piece structure, all of which are formed by lapping multiple stacks of amorphous alloy strips, forming a circular rectangle, and the lap joints 11 face the same side. In this embodiment, there are two amorphous core bodies 1, which are divided into upper and lower layers. put. The pull plates 2 are respectively located on the bottom surface of the lower amorphous core body 1 and the upper surface of the upper amorphous core body 1, which include a horizontal bottom plate 5 and three vertical plates 6, and the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com