Water quantity control method for a food processing machine

A technology for food processing machines and water volume control, applied in non-electric variable control, liquid level control, control/regulation systems, etc., can solve the problem of inability to detect how much water is placed in the water tank, high cost of flow meter detection solutions, and inability to meet general needs and other problems, to avoid pulping performance problems, have versatility, and shorten the number of pumping times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

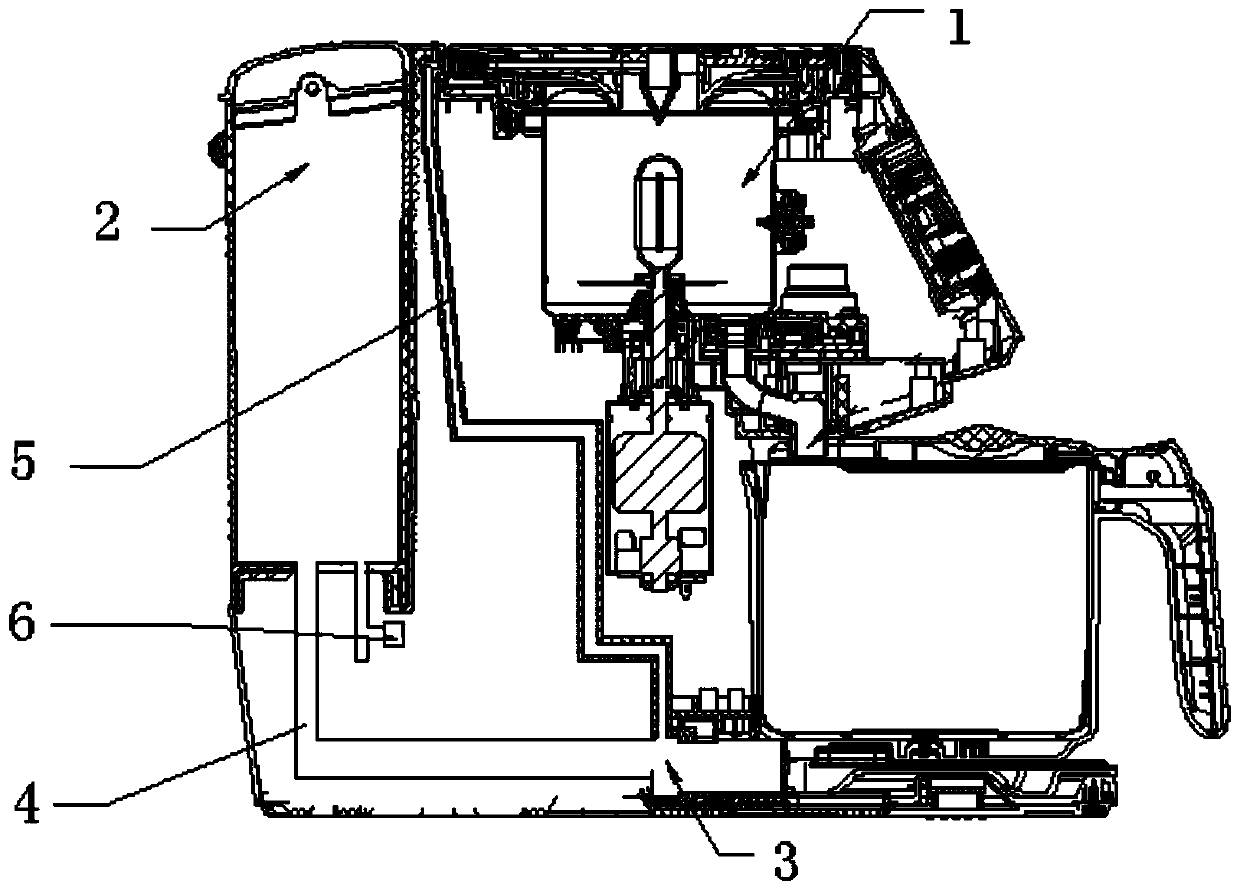

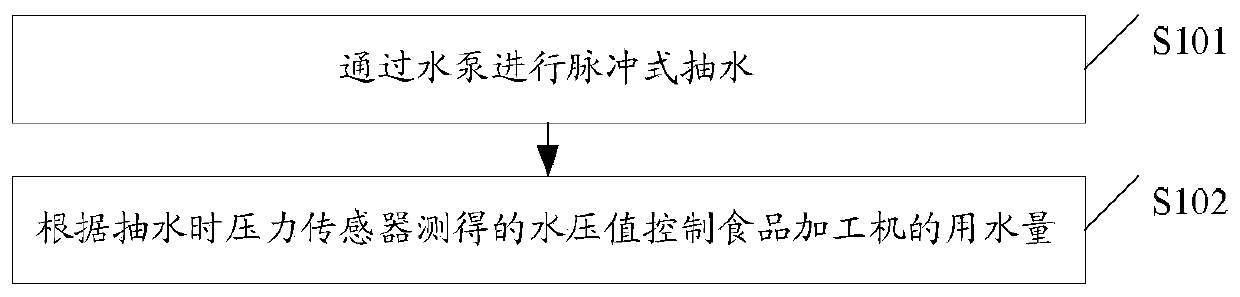

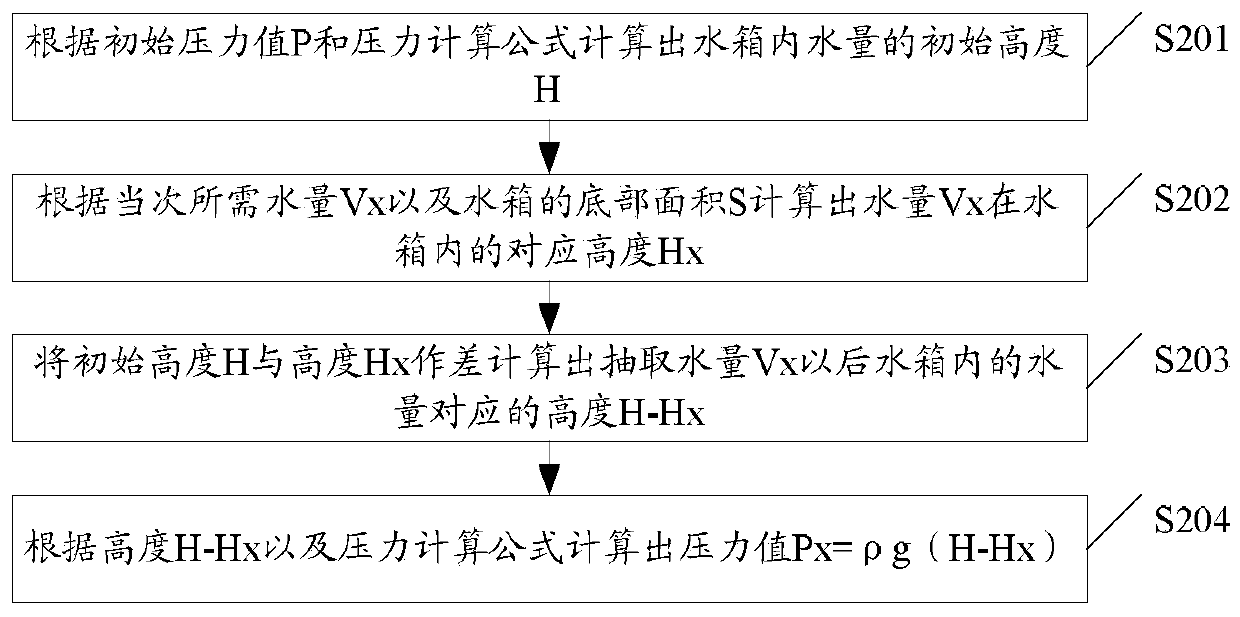

[0057] A method for controlling the amount of water in a food processor, such as figure 1 As shown, the food processor includes: a crushing cavity 1, a water tank 2, a water pump 3, a water inlet pipe 4 connecting the water tank 2 and the water pump, and a water pipe 5 connecting the crushing cavity 1 and the water pump 2. The water pump 2 draws the water tank 2 through the water inlet pipe 4 The food processing machine also includes a pressure sensor 6, such as figure 2 As shown, the method may include S101-S102:

[0058] S101. Pulse water pumping through a water pump.

[0059] In the embodiment of the present invention, the current food processing opportunity adopts the principle of small space crushing, which has strict requirements on the ratio of soybean to water. Therefore, the amount of water injected into the crushing cavity 1 needs to be accurately set. The current water level detection scheme, such as water level The electrode method can only measure a few fixed capaciti...

Embodiment 2

[0078] The difference between this embodiment and the first embodiment is that the pumping time of the water pump 3 is further restricted to achieve the optimization of the pumping time.

[0079] In the embodiment of the present invention, when the water pump 3 performs pulse pumping, if the single pumping time of the water pump 3 is too long, the measurement accuracy is too low, the water injection volume deviates greatly from the set value, and the single pumping time is too short, causing The longer pumping time affects the pulping cycle, so the pumping time needs to be optimized.

[0080] In the embodiment of the present invention, before the pulse pumping is performed by the water pump 3, the average water flow velocity v when the water pump 3 is pumping can be obtained in advance through multiple tests to average, and on the basis of obtaining the average water flow velocity v , Knowing the water volume Vx required at the time, the total time required to extract the water vol...

Embodiment 3

[0096] The difference between this embodiment and the second embodiment is that another optimization scheme is implemented for the pumping time of the water pump 3, which successively reduces the pumping time of each pulse.

[0097] Optionally, the method further includes: pumping water in a manner of successively reducing the pumping time of each pulse until the pumped water volume meets Vx±δVx, then the pumping is stopped.

[0098] In the embodiment of the present invention, since the set water volume Vx is a relatively large value relative to the water volume of a single pump, it may take many pumping times to reach Vx, so it may take too long to pump water to the set water volume Vx At the same time, frequent starting and closing of the water pump will also have a certain impact on the life of the water pump, so the gradual approach method can be used for pumping.

[0099] Optionally, such as Image 6 As shown, performing pumping in a manner of successively reducing the pumping t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com