Special environment-friendly lubricating oil for seal rings of internal mixers for tires

An internal mixer and sealing ring technology, used in lubricating compositions, petroleum industry and other directions, can solve the problems of not meeting environmental protection requirements, failing to meet environmental protection regulations, and cracking down on the tire industry, achieving good social benefits, increasing the scope of use, The effect of extending the life of the seal ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

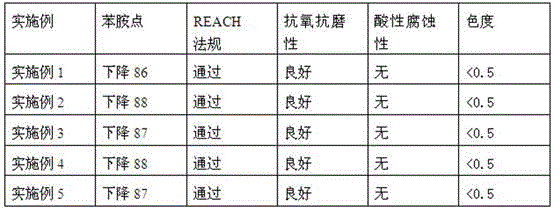

Embodiment 1

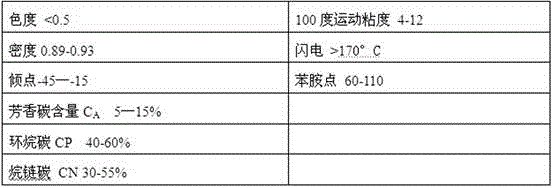

[0013] Embodiment 1, a kind of special environment-friendly lubricating oil for the sealing ring of tire internal mixer that the present invention mentions, its preparation formula is as follows (by weight):

[0014] 85 parts of environmentally friendly naphthenic oil, 8.3 parts of dioctyl terephthalate, 3 parts of dialkylmolybdenum dithiophosphate, 0.10 parts of emulsified silicone oil, 2 parts of high alkali value sulfurized alkyl phenate calcium, dialkyl dithiophosphate 1.6 parts of zinc phosphate.

Embodiment 2

[0026] Embodiment 2, a kind of special environment-friendly lubricating oil for the sealing ring of tire internal mixer mentioned in the present invention, its preparation formula is as follows (by weight):

[0027] 86 parts of environmentally friendly naphthenic oil, 6.3 parts of dioctyl terephthalate, 5 parts of dialkylmolybdenum dithiophosphate, 0.12 parts of emulsified silicone oil, 2.5 parts of high alkali value sulfurized alkyl phenate calcium, dialkyl dithiophosphate 1.3 parts of zinc phosphate.

Embodiment 3

[0030] Embodiment 3, a kind of special environment-friendly lubricating oil for the sealing ring of tire internal mixer mentioned in the present invention, its preparation formula is as follows (by weight):

[0031] 85 parts of environmentally friendly naphthenic oil, 7.27 parts of dioctyl terephthalate, 3 parts of dialkylmolybdenum dithiophosphate, 0.13 parts of emulsified silicone oil, 0.8 parts of high alkali value sulfurized alkyl phenate calcium, dialkyl dithiophosphate 1 part zinc phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com