motor power unit

A power plant and motor type technology, applied in power plant, electric power plant, electromechanical device and other directions, can solve the problems of easy oil immersion, large-scale, complicated casing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

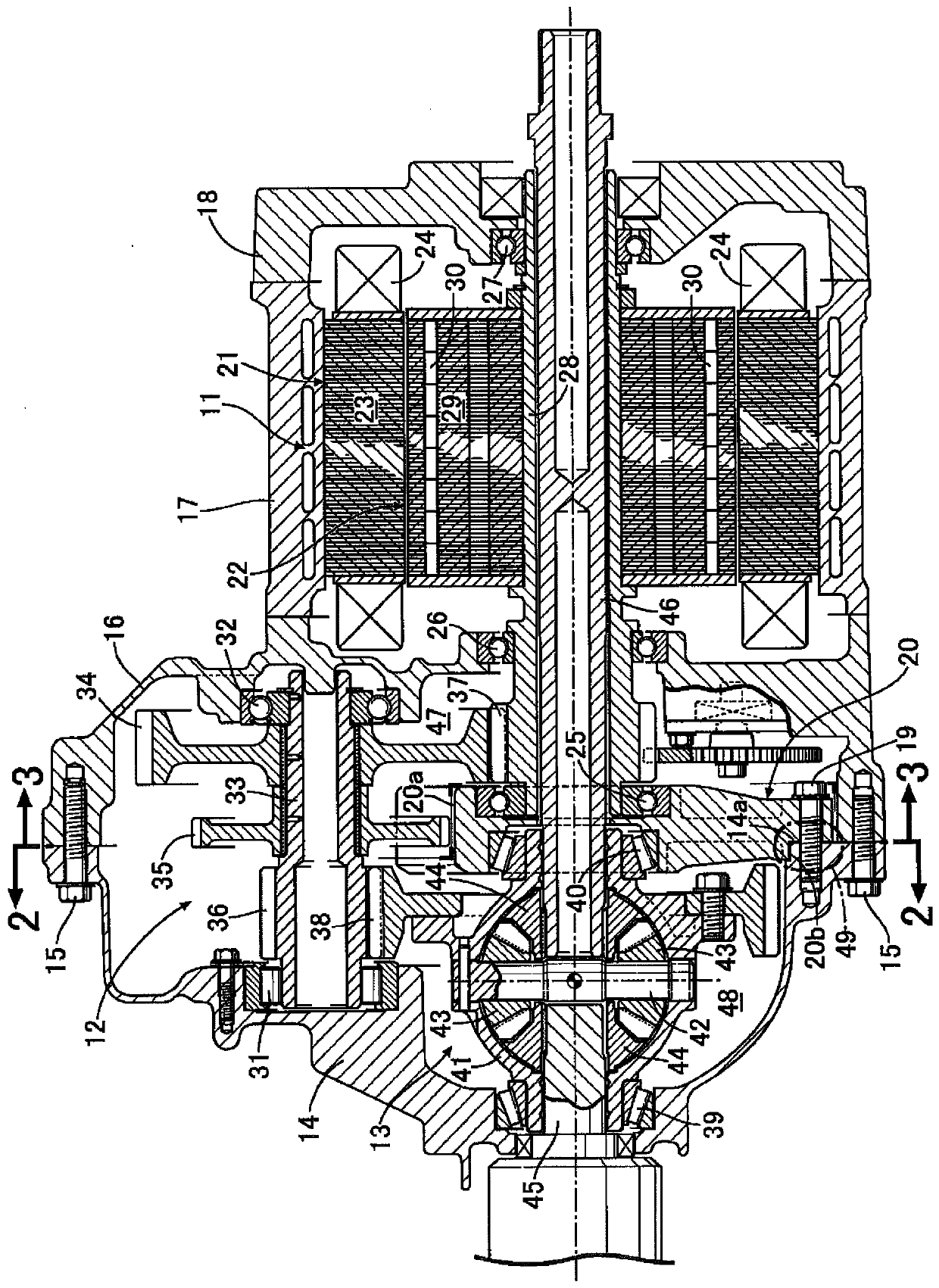

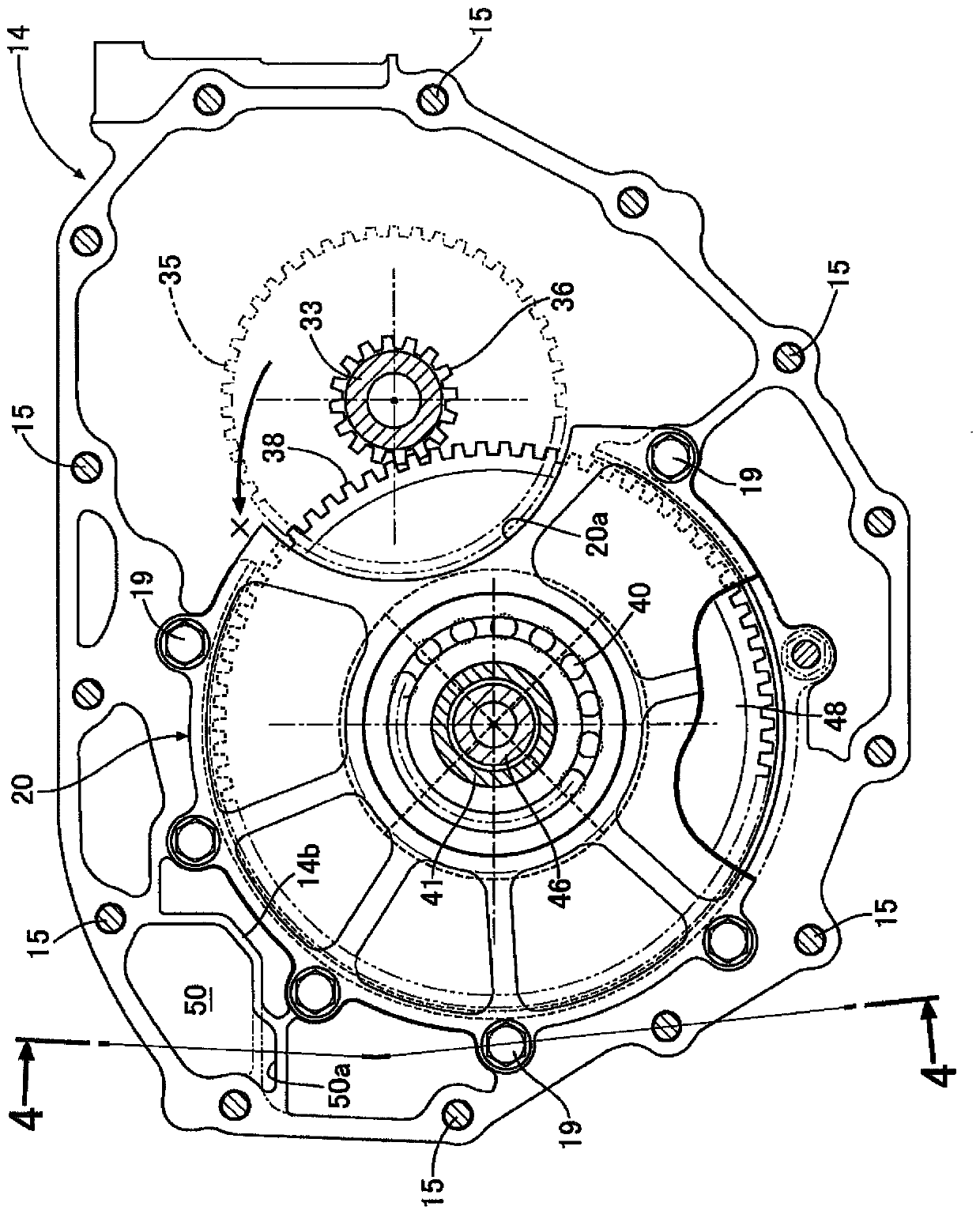

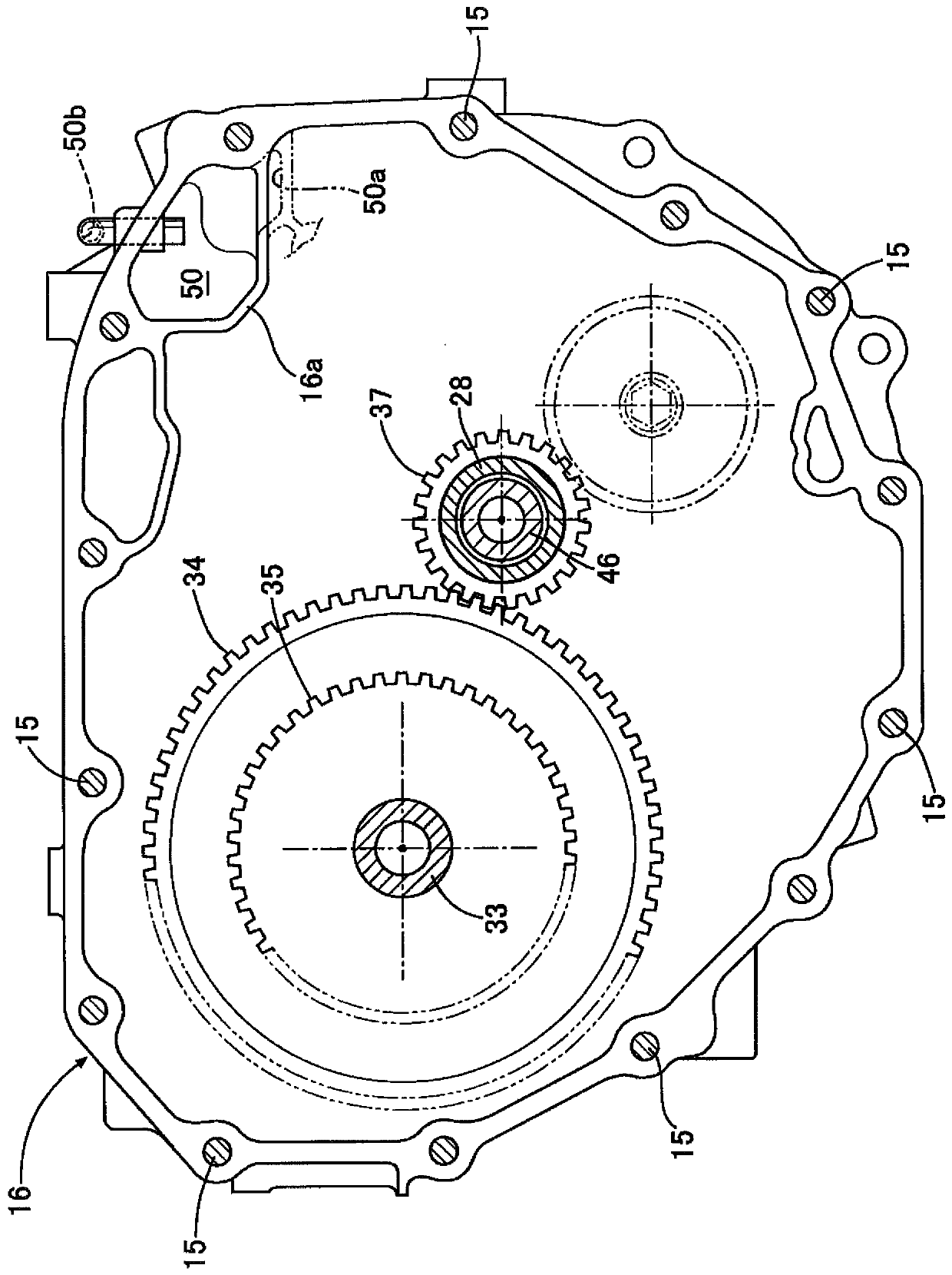

[0025] Below, according to Figure 1 to Figure 5 Embodiments of the present invention will be described.

[0026] Such as figure 1 As shown, the motor-type power unit used as the power unit of the electric vehicle integrally has an electric motor 11, a speed reducer 12 and a differential 13, and the outer contour of the motor-type power unit is composed of the following parts: The transmission case 14; the motor / transmission case 16 connected to the right end of the transmission case 14 by bolts 15; the motor center case 17 connected to the right end of the motor / transmission case 16 by unillustrated bolts; The motor side case 18 at the right end of the motor center case 17; the middle case 20 bonded to the inner surface of the transmission case 14 with bolts 19 . . .

[0027] The electric motor 11 is housed inside the motor center case 17 and the motor side case 18 . In addition, the intermediate case 20 partitions the inside of the transmission case 14 and the motor / trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com