Underwater motor

A motor and main body technology, applied in electromechanical devices, coupling devices, electrical components, etc., can solve problems such as damaged cables, poor wiring workability, and poor workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] specific implementation

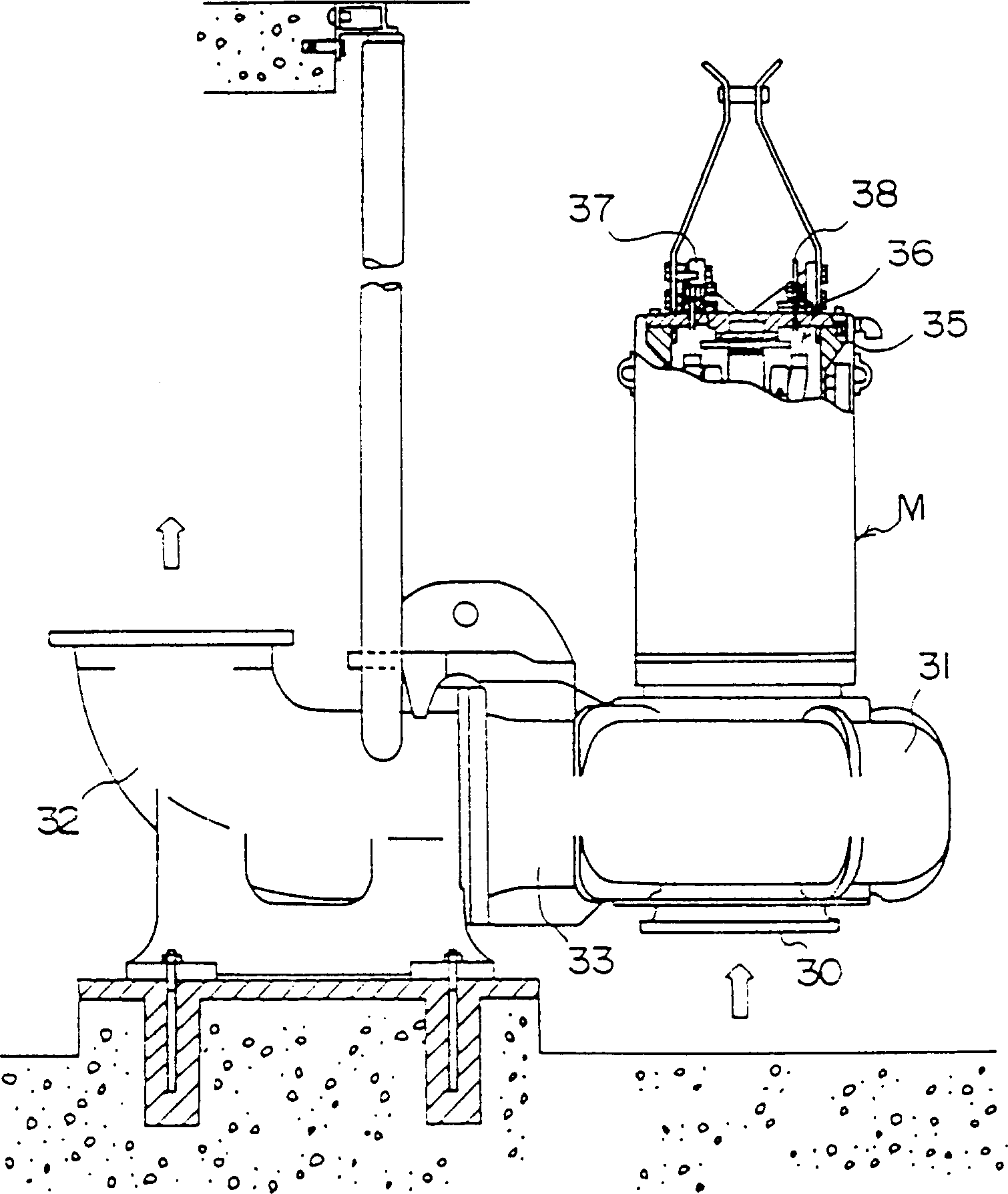

[0037] figure 1 A vertical shaft type submersible pump using the submersible motor of the present invention is shown. An impeller is provided in a pump casing 33 having a suction port 30 , a scroll chamber 31 , and a discharge pipe 32 , and an underwater motor M is assembled above the pump casing 33 . The structure of the underwater motor M is that the motor body 36 is incorporated into the cylindrical motor box 35 , and the structure of its connector is: a power cable 37 and a control cable 38 are detachably connected on the top of the motor box 35 .

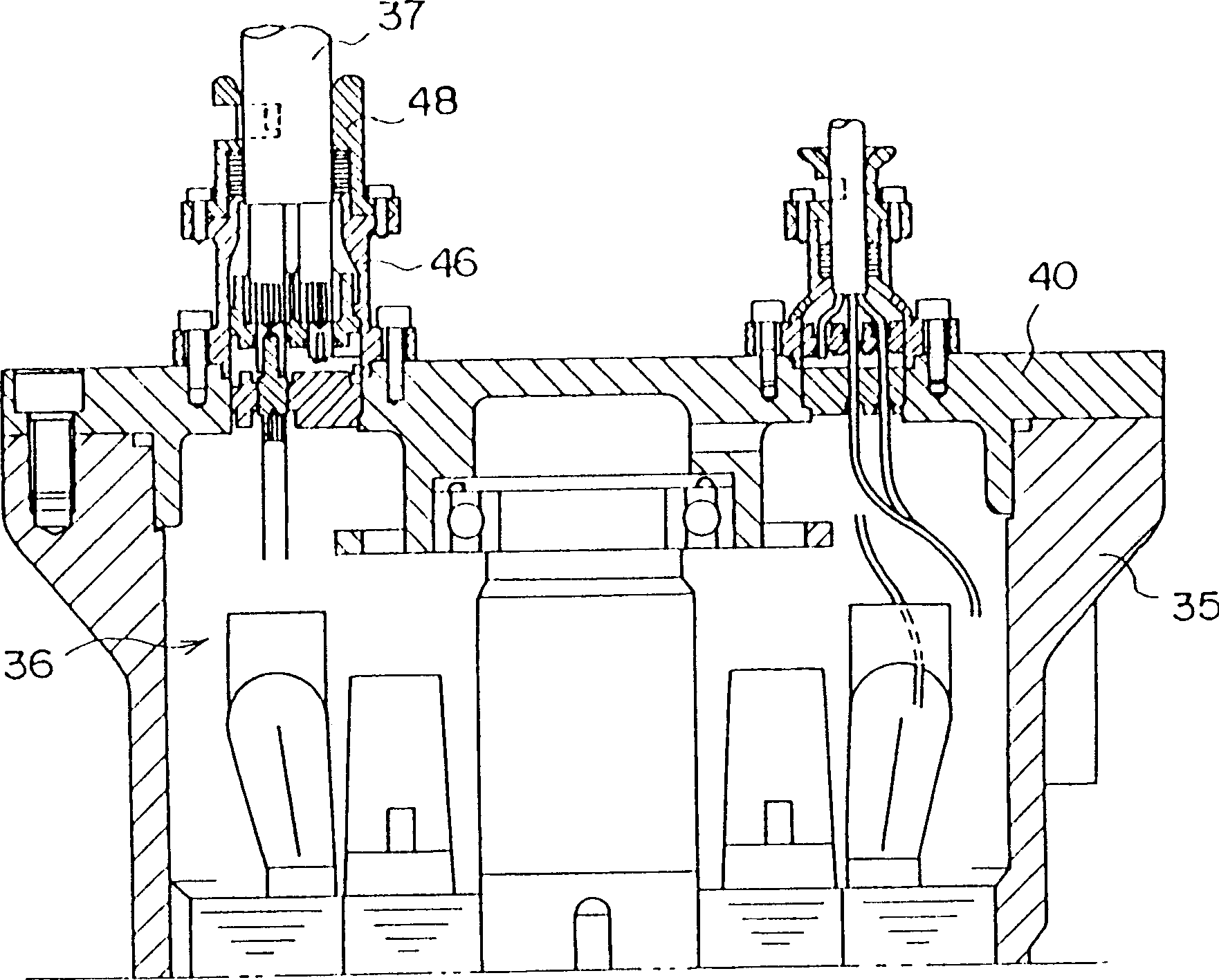

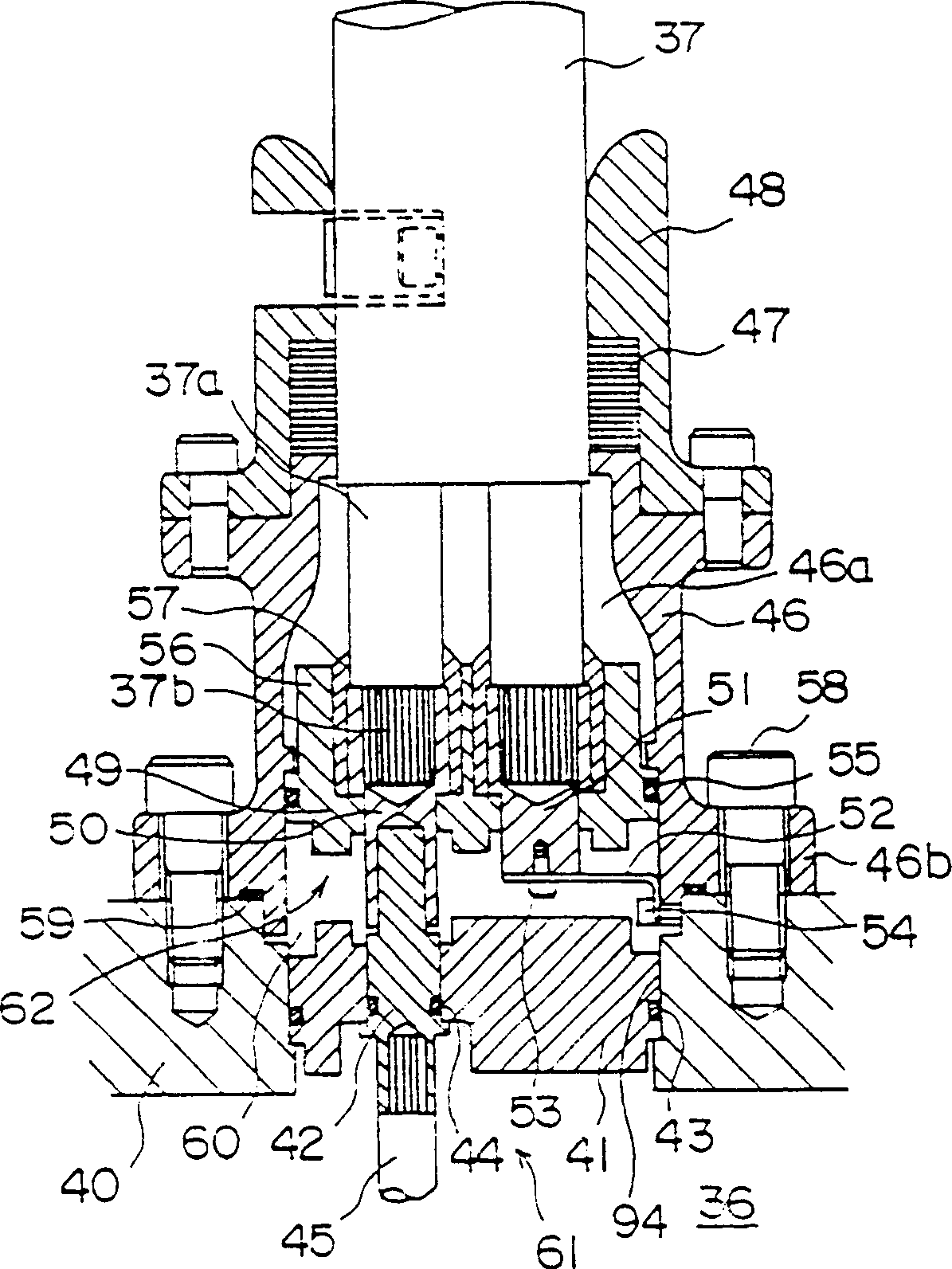

[0038] Such as figure 2 or image 3 As shown, on the motor body 36 side, a cover plate 41 made of an insulator is attached to the opening of the top plate 40 of the box 35, and a male side connector 42 protruding outward is provided on the cover plate 41. The top corner of the joint 42 is chamfered into a rounded guide face 42a. Between the top plate 40 and the cover plate 41 , and betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com