L-shaped elbow clamping device

A technology of clamping device and pipe bending, applied in the direction of clamping device, workpiece clamping device, positioning device, etc., can solve the problems of difficult clamping, unsuitable for L-shaped elbow clamping, etc., and achieve smooth left and right motion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

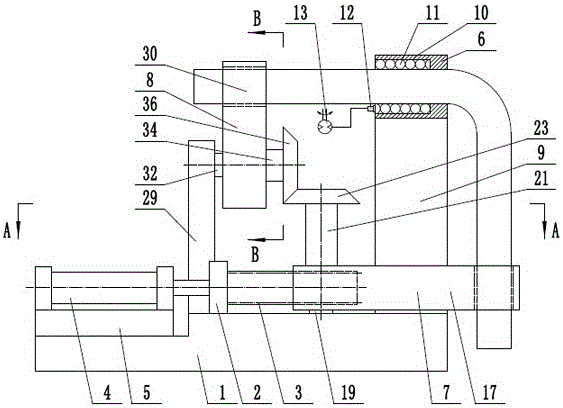

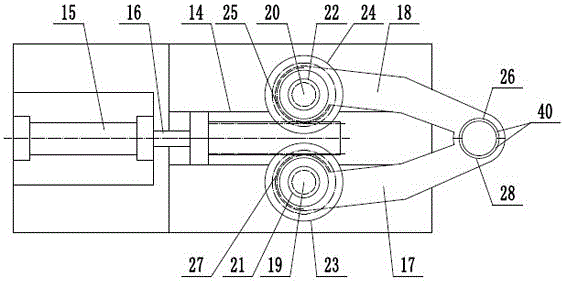

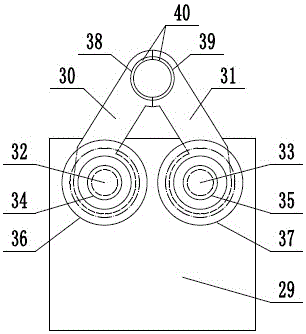

[0015] Such as figure 1 , figure 2 and image 3As shown, an L-shaped elbow clamping device includes a frame 1, a rack support block 2, a rack 3, a drive cylinder 4, a cylinder support 5, a positioning support mechanism 6, a horizontal clamping mechanism 7, a vertical The straight clamping mechanism 8 and the positioning support mechanism 6 realize the positioning and support of the L-shaped elbow, and the horizontal clamping mechanism 7 and the vertical clamping mechanism 8 realize the synchronous clamping of the two ends of the L-shaped elbow. The positioning support mechanism 5 includes a support frame 9, a positioning support plate 10, an expansion air pipe 11, a vent valve 12, and an air pump 13. The position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com