Co-based catalyst for production of sulfur through reduction of SO2 in flue gas as well as preparation method and application of Co-based catalyst

A catalyst and flue gas technology, which is applied in the field of Co-based catalysts for producing elemental sulfur from flue gas SO2 and its preparation field, can solve the problems of poor activity, unsuitable for large-scale production, complicated preparation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

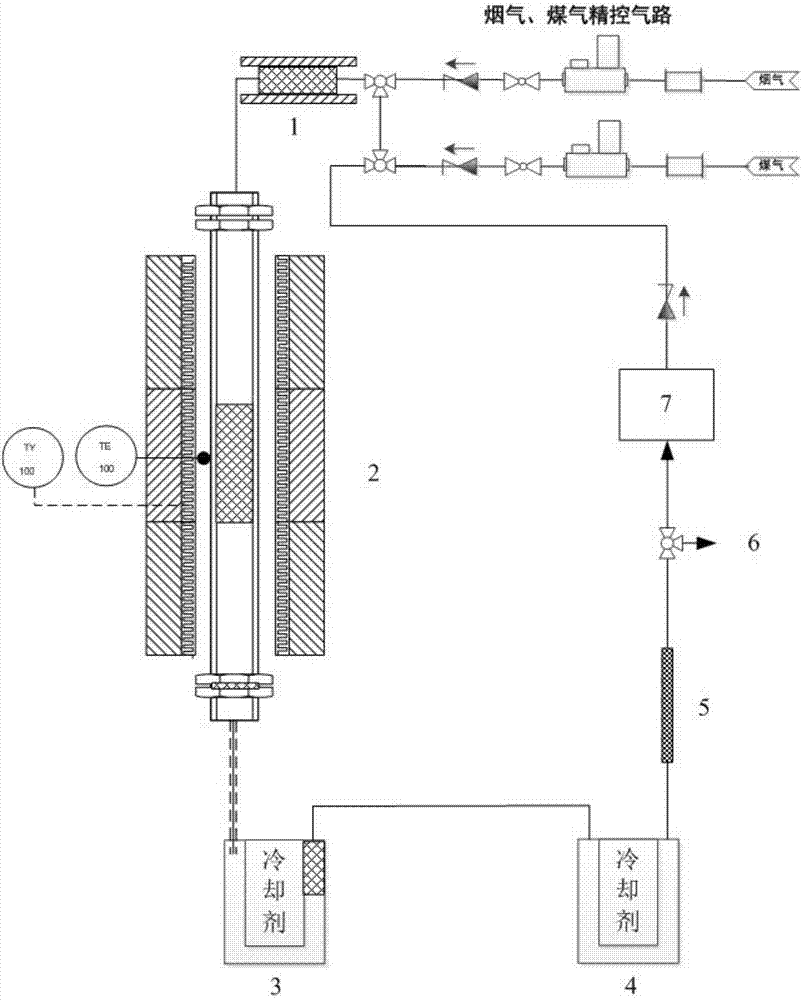

Image

Examples

Embodiment 1

[0064] This embodiment provides a method for SO in flue gas 2 A Co-based catalyst for reducing sulfur production and a preparation method thereof, the method comprising the following steps:

[0065] (1) Weigh 15g of γ-Al with a fixed mesh 2 o 3 Granules, put into a small beaker, gradually drop deionized water, when the water is just fully impregnated γ-Al 2 o 3 Stop dripping water when the time comes, weigh and calculate the amount of water added, and determine 15g of carrier γ-Al 2 o 3 Water absorption 15.3g;

[0066] (2) Calculate and prepare 14wt% Co / γ-Al according to the mass of carrier 2 o 3 Co(NO 3 ) 2 ·6H 2 The amount of O, wherein 14% is the ratio of the mass of the metal oxide to the mass of the support. 8.16g of Co(NO 3 ) 2 ·6H 2 O was dissolved in 15.3mL of deionized water, stirred until completely dissolved to form the desired concentration of Co(NO 3 ) 2solution; then pour the solution into 15g of γ-Al 2 o 3 Put it in a small beaker of the carrie...

Embodiment 2

[0071] This embodiment provides a method for SO in flue gas 2 A Co-based catalyst for reducing sulfur production and a preparation method thereof, the method comprising the following steps:

[0072] (1) Weigh 15g of γ-Al with a fixed mesh 2 o 3 Granules, put into a small beaker, gradually drop deionized water, when the water is just fully impregnated γ-Al 2 o 3 Stop dripping water when the time comes, weigh and calculate the amount of water added, and determine 15g of carrier γ-Al 2 o 3 Water absorption 15.3g;

[0073] (2) Calculate the preparation of 14% Co-4% Cu / γ-Al according to the mass of the carrier 2 o 3 Co(NO 3 ) 2 ·6H 2 O and Cu(NO 3 ) 2 ·3H 2 The amount of O. 8.16g of Co(NO 3 ) 2 ·6H 2 O and 1.82g of Cu(NO 3 ) 2 ·3H 2 Dissolve O in 15.3mL of deionized water, stir until it is completely dissolved to form an impregnation solution of the required concentration; then pour this solution into 15g of γ-Al 2 o 3 Put it in a small beaker of the carrier, ...

Embodiment 3

[0078] This embodiment provides a method for SO in flue gas 2 A Co-based catalyst for reducing sulfur production and a preparation method thereof, the method comprising the following steps:

[0079] (1) Weigh 15g of γ-Al with a fixed mesh 2 o 3 Granules, put into a small beaker, gradually drop deionized water, when the water is just fully impregnated γ-Al 2 o 3 Stop dripping water when the time comes, weigh and calculate the amount of water added, and determine 15g of carrier γ-Al 2 o 3 Water absorption 15.3g;

[0080] (2) Calculate and prepare 14%Co-4%Cu-2%La / γ-Al according to the mass of the carrier 2 o 3 Co(NO 3 ) 2 ·6H 2 O, Cu(NO 3 ) 2 ·3H 2 O and La(NO 3 ) 3 ·6H 2 The amount of O. 8.16g of Co(NO 3 ) 2 ·6H 2 O, 1.82g of Cu(NO 3 ) 2 ·3H 2 O and 0.9352g of La(NO 3 ) 3 ·6H 2 O was dissolved in 15.3mL of deionized water and stirred until completely dissolved to form an impregnation solution of the desired concentration. Then pour the solution into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com