Dichromium trioxide catalyst for catalyzing ethane to prepare ethylene and preparation thereof

A technology of chromium trioxide and catalyst, applied in the field of chromium trioxide catalyst and preparation thereof, can solve the problems of low conversion rate and selectivity and high reaction temperature, achieve good catalytic activity, low reaction temperature, and simplify product post-processing The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

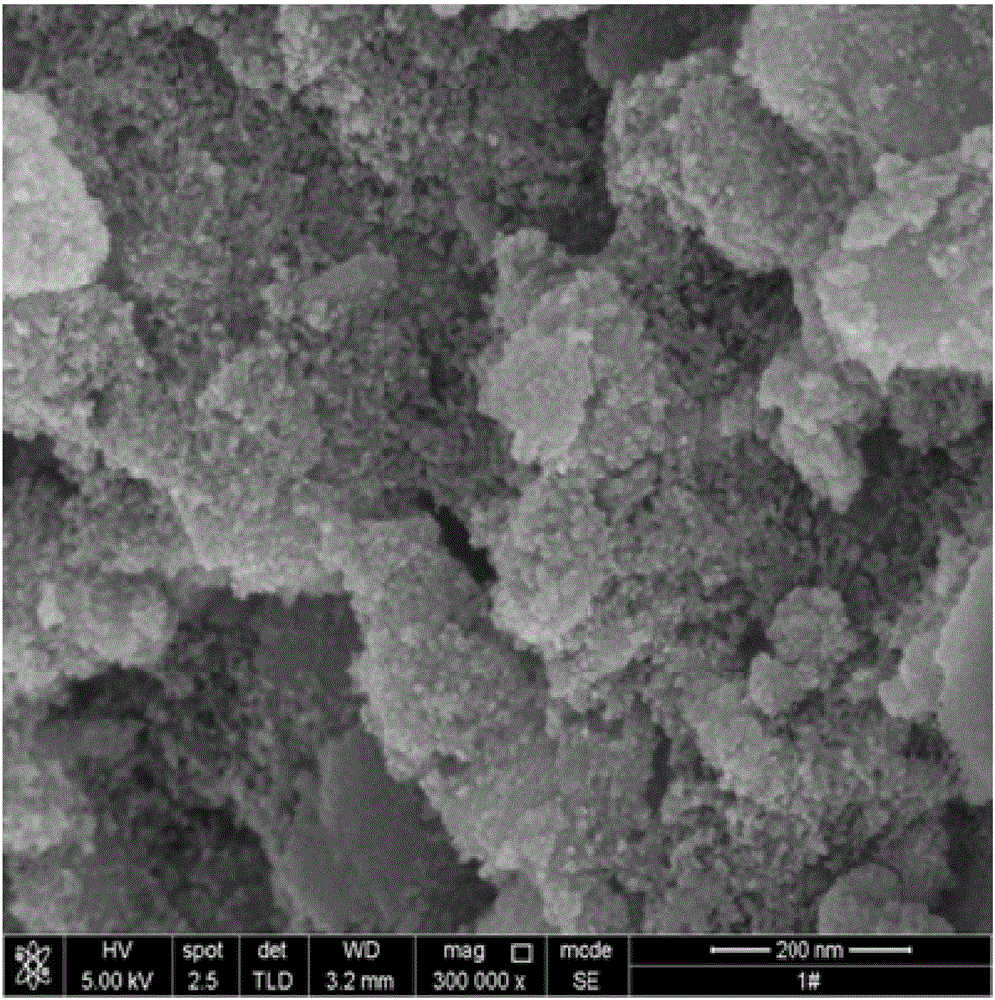

Embodiment 1

[0049] Mix 0.1mol / L urea aqueous solution and 0.038mol / L chromium nitrate aqueous solution at a volume ratio of 1.5:1, stir, and react at 95°C for 6h. The reaction product was then aged at 25 °C for 12 h. The aged product was filtered, washed with distilled water until the filtrate was neutral. Suction filter the filter residue until it is anhydrous, and obtain a wet gel. Soak the wet gel in absolute ethanol for 12 hours, and then filter; continue to treat the treated wet gel with ethanol once more to obtain an alcohol gel. The alcohol gel was air dried. Then the alcohol gel was immersed in 10wt% TEOS / ethanol solution and reacted at 25°C for 12h. The reaction product was filtered and washed three times with ethanol. The obtained solid product was dried at 80°C, then calcined at 600°C, pressed into tablets, pulverized and sieved to form 40-mesh granules to obtain a chromium trioxide catalyst.

Embodiment 2

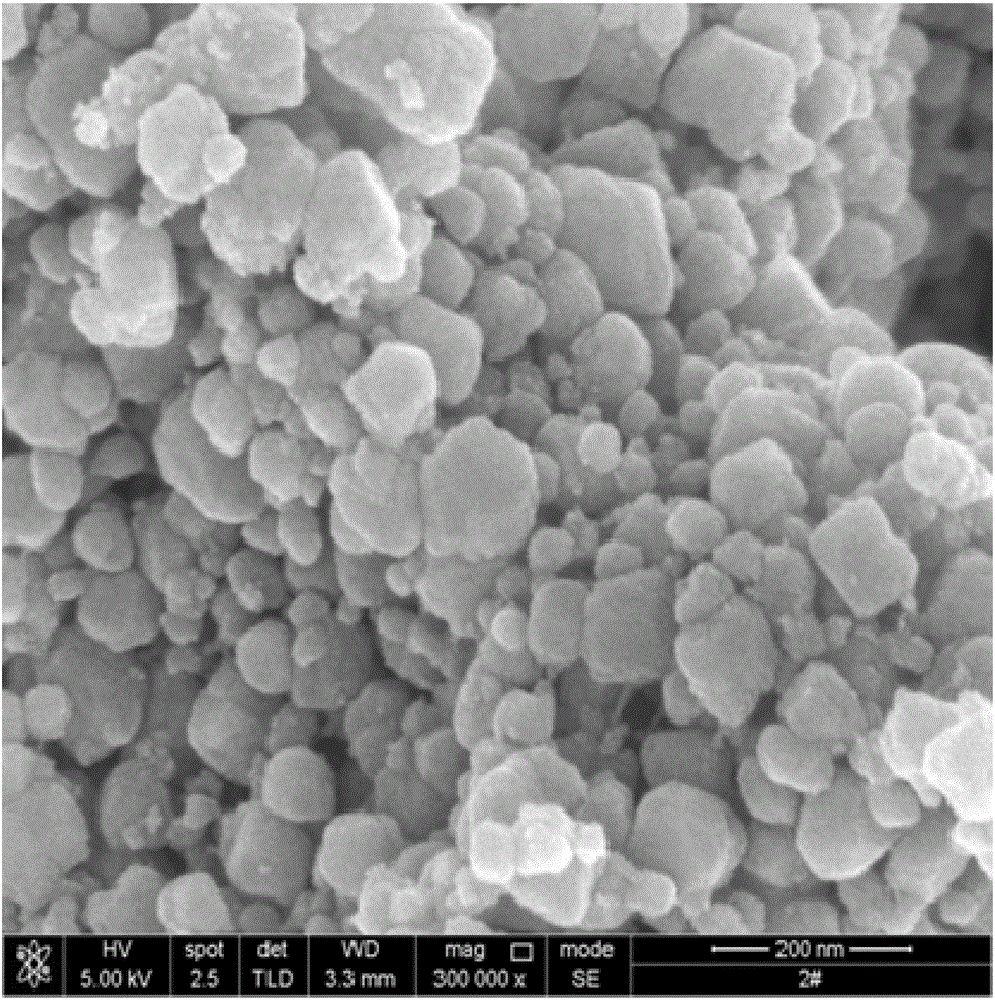

[0051] Mix 0.09mol / L urea aqueous solution and 0.075mol / L chromium nitrate aqueous solution at a volume ratio of 2:1, stir, and react at 90°C for 6h. The reaction product was then aged at 25 °C for 12 h. The aged product was filtered, washed with distilled water until the filtrate was neutral. Drain the filter residue as much as possible to obtain a wet gel. Soak the wet gel in absolute ethanol for 12 hours, and then filter; continue to treat the treated wet gel with ethanol twice to obtain an alcohol gel. The alcohol gel was air dried. Then the alcohol gel was immersed in 1wt% TEOS / ethanol solution and reacted at 50°C for 12h. The reaction product was filtered and washed three times with ethanol. The obtained solid product was dried at 80°C, then calcined at 600°C, pressed into tablets, crushed and sieved to form 20-mesh granules to obtain a chromium trioxide catalyst.

Embodiment 3

[0053] Mix 0.12mol / L urea aqueous solution and 0.05mol / L chromium nitrate aqueous solution at a volume ratio of 1:1, stir, and react at 95°C for 6h. The reaction product was then aged overnight at room temperature. The aged product was filtered, washed with distilled water until the filtrate was neutral. Suction filter the filter residue until it is anhydrous, and obtain a wet gel. The wet gel was soaked in absolute ethanol overnight, and then filtered; the treated wet gel was continued to be treated with ethanol once more to obtain an alcohol gel. The alcohol gel was air dried. Then the alcohol gel was immersed in 3wt% TEOS / ethanol solution and reacted overnight at room temperature. The reaction product was filtered and washed three times with ethanol. The obtained solid product was dried at 80° C., then calcined at 600° C., pressed into tablets, pulverized and sieved to form 30-mesh granules to obtain a chromium trioxide catalyst.

PUM

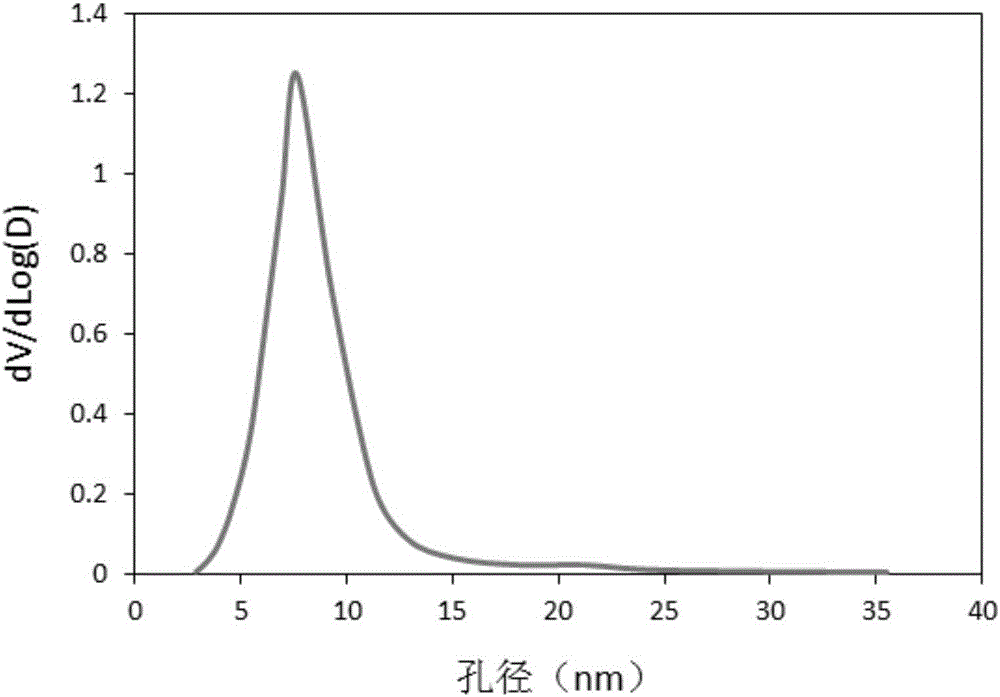

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com