Calcium carbide furnace tail gas recycling device

A calcium carbide furnace tail gas, calcium carbide furnace technology, applied in the direction of combined devices, gas treatment, climate change adaptation, etc., can solve the problems of endangering human health, environmental pollution, noise pollution, etc., achieve a wide range of use, reduce noise pollution, and dust The effect of volume and temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

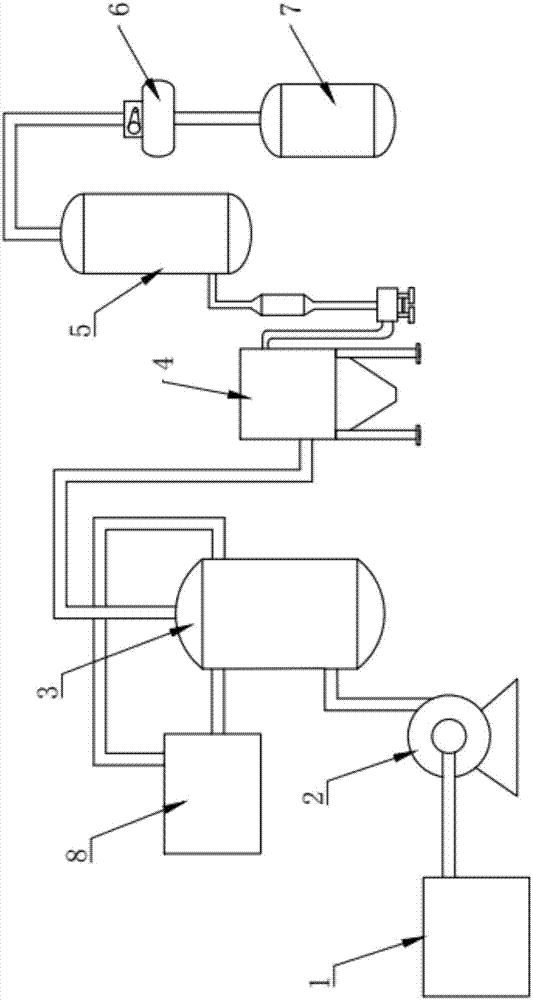

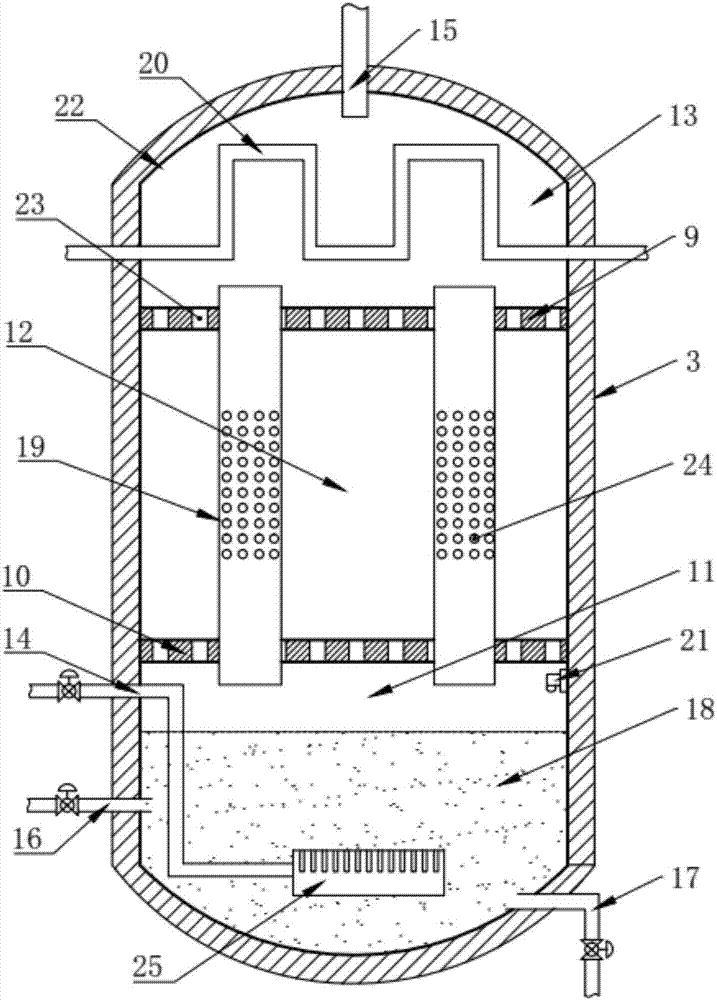

[0033] Such as figure 1 and figure 2 As shown, the present invention provides a recovery and utilization device for calcium carbide furnace 1 tail gas, comprising calcium carbide furnace 1, the tail gas outlet of calcium carbide furnace 1 is connected with induced draft fan 2, noise reduction and environmental protection absorption tank 3, cyclone separator 4, spray Washing tower 5, gas compressor 6 and synthesis reactor 7; after the exhaust gas of calcium carbide furnace 1 drawn from induced draft fan 2 is water-cooled, noise-reduced, air-cooled, purified and dust-removed and compressed, the temperature, pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com