Zirconium-containing metal organic framework material modified open tubular capillary column and application thereof

A metal-organic framework and open-tube capillary column technology is applied in the field of chromatographic columns to achieve the effects of simple process, easy operation and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

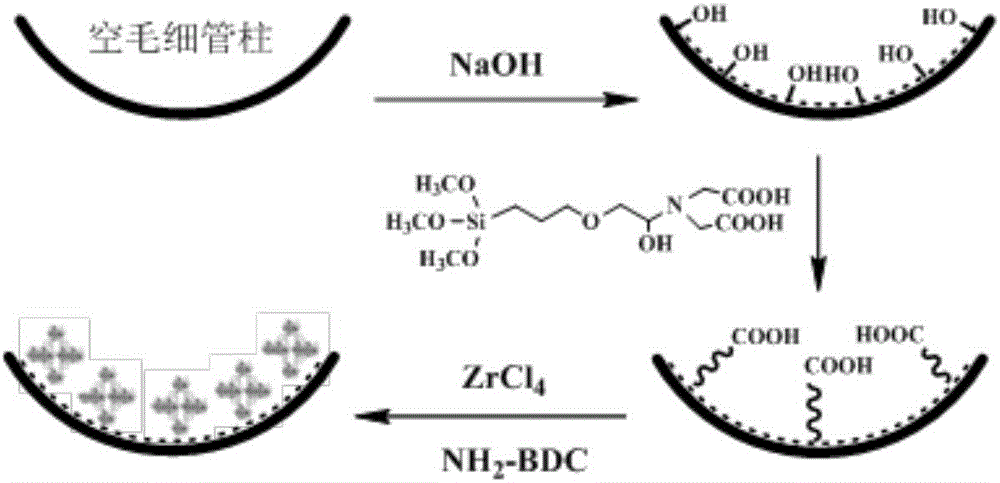

[0024] A 33.5 cm long quartz capillary (50 µm i.d. × 375 µm o.d.) was first washed with 1 M NaOH solution for 2 h, and then sequentially washed with H 2 O, 1 M HCl solution rinsed for 10 min, H 2 O was rinsed for 30 min, blown dry with nitrogen, and finally dried in an oven at 100 °C for 1 h. Take 2.125 g of iminodiacetic acid (IDA), add 25 mL of water, and adjust the pH to 11 with 10 mol / L sodium hydroxide. Under ice-bath conditions, stir and add 0.7 mL of 3-glycidyloxypropyltrimethoxysilane (GLYMO). The mixture was stirred at 65 °C for 6 h, then the ice bath was lowered to 0 °C, and 0.8 mL of GLYMO was added. Continue to stir at 65 °C for 6 h, then lower the ice bath to 0 °C, add 0.85 mL GLYMO, stir overnight at 65 °C, and finally adjust the pH to 6 with concentrated hydrochloric acid. The obtained solution was passed into the pretreated capillary column, and reacted in a water bath at 95 °C for 12 h, then washed with methanol and water respectively, and dried with nitrog...

Embodiment 2

[0026] A 33.5 cm long quartz capillary (50 µm i.d. × 375 µm o.d.) was first washed with 1 M NaOH solution for 2 h, and then sequentially washed with H 2 O, 1 M HCl solution rinsed for 10 min, H 2 O was rinsed for 30 min, blown dry with nitrogen, and finally dried in an oven at 100 °C for 1 h. Take 2.125 g of iminodiacetic acid (IDA), add 25 mL of water, and adjust the pH to 11 with 10 mol / L sodium hydroxide. Under ice-bath conditions, stir and add 0.7 mL of 3-glycidyloxypropyltrimethoxysilane (GLYMO). The mixture was stirred at 65 °C for 6 h, then the ice bath was lowered to 0 °C, and 0.8 mL of GLYMO was added. Continue to stir at 65 °C for 6 h, then lower the ice bath to 0 °C, add 0.85 mL GLYMO, stir overnight at 65 °C, and finally adjust the pH to 6 with concentrated hydrochloric acid. The obtained solution was passed through the pretreated capillary column, reacted in a water bath at 90 °C for 16 h, then washed with methanol and water, and dried with nitrogen to obtain a...

Embodiment 3

[0028] A 33.5 cm long quartz capillary (50 µm i.d. × 375 µm o.d.) was first washed with 1 M NaOH solution for 2 h, and then sequentially washed with H 2 O, 1 M HCl solution rinsed for 10 min, H 2O was rinsed for 30 min, blown dry with nitrogen, and finally dried in an oven at 100 °C for 1 h. Take 2.125 g of iminodiacetic acid (IDA), add 25 mL of water, and adjust the pH to 11 with 10 mol / L sodium hydroxide. Under ice-bath conditions, stir and add 0.7 mL of 3-glycidyloxypropyltrimethoxysilane (GLYMO). The mixture was stirred at 65 °C for 6 h, then the ice bath was lowered to 0 °C, and 0.8 mL of GLYMO was added. Continue to stir at 65 °C for 6 h, then lower the ice bath to 0 °C, add 0.85 mL GLYMO, stir overnight at 65 °C, and finally adjust the pH to 6 with concentrated hydrochloric acid. The obtained solution was passed into the pretreated capillary column, reacted in a water bath at 100 °C for 16 h, then washed with methanol and water, and dried with nitrogen to obtain a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com